Smooth-surface geomembrane and preparation method thereof

A technology of geomembrane and smooth surface, which is applied in the field of smooth geomembrane and its preparation, can solve the problems of being unable to meet multiple environments, multiple changes, resistance to environmental stress cracking, and single formula, and achieve excellent resistance to environmental stress cracking and mechanical properties The effect of balance and flexibility can be highlighted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

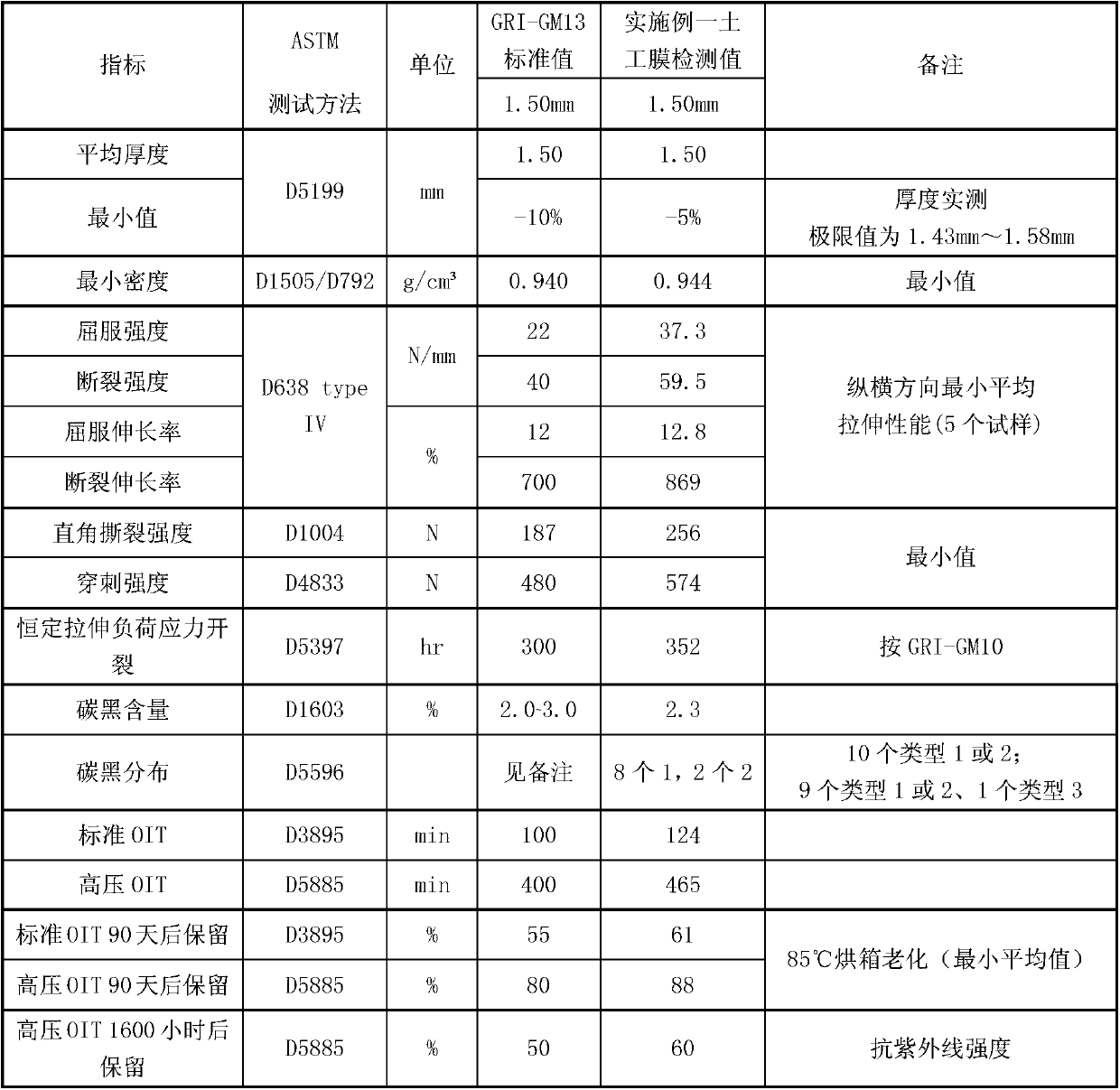

Embodiment 1

[0020] (1) According to the following formula: the raw material is composed of 100 parts of MDPE and 8 parts of LLDPE; then add the carbon black of 5.4% of the weight of the raw material, the antioxidant of 0.3% of the weight of the raw material, and the light stabilizer of 0.2% of the weight of the raw material. MDPE has a bimodal distribution of molecular weight, butene copolymerization, a comonomer content of about 3%, and a density of 0.936g / cm 3 ~0.938g / cm 3 , Medium density polyethylene with a melt flow rate MFR of 0.1-0.2g / 10min (190°C, 2.16kg). LLDPE is octene copolymer, density 0.920g / cm 3 ~0.925g / cm 3 , Linear low density polyethylene with a melt flow rate MFR of 0.8-1.0g / 10min (190°C, 2.16kg). Carbon black is nano-scale particle size (20-25nm), concentration 45-48%, carrier uses LDPE, density 1.20g / cm 3 ~1.25g / cm 3 , Melt flow rate MFR of 2.0 ~ 2.5g / 10min (190 ℃, 2.16kg) medium pigment carbon black masterbatch, as a UV shielding agent. The antioxidant is 2,6-t...

Embodiment 2

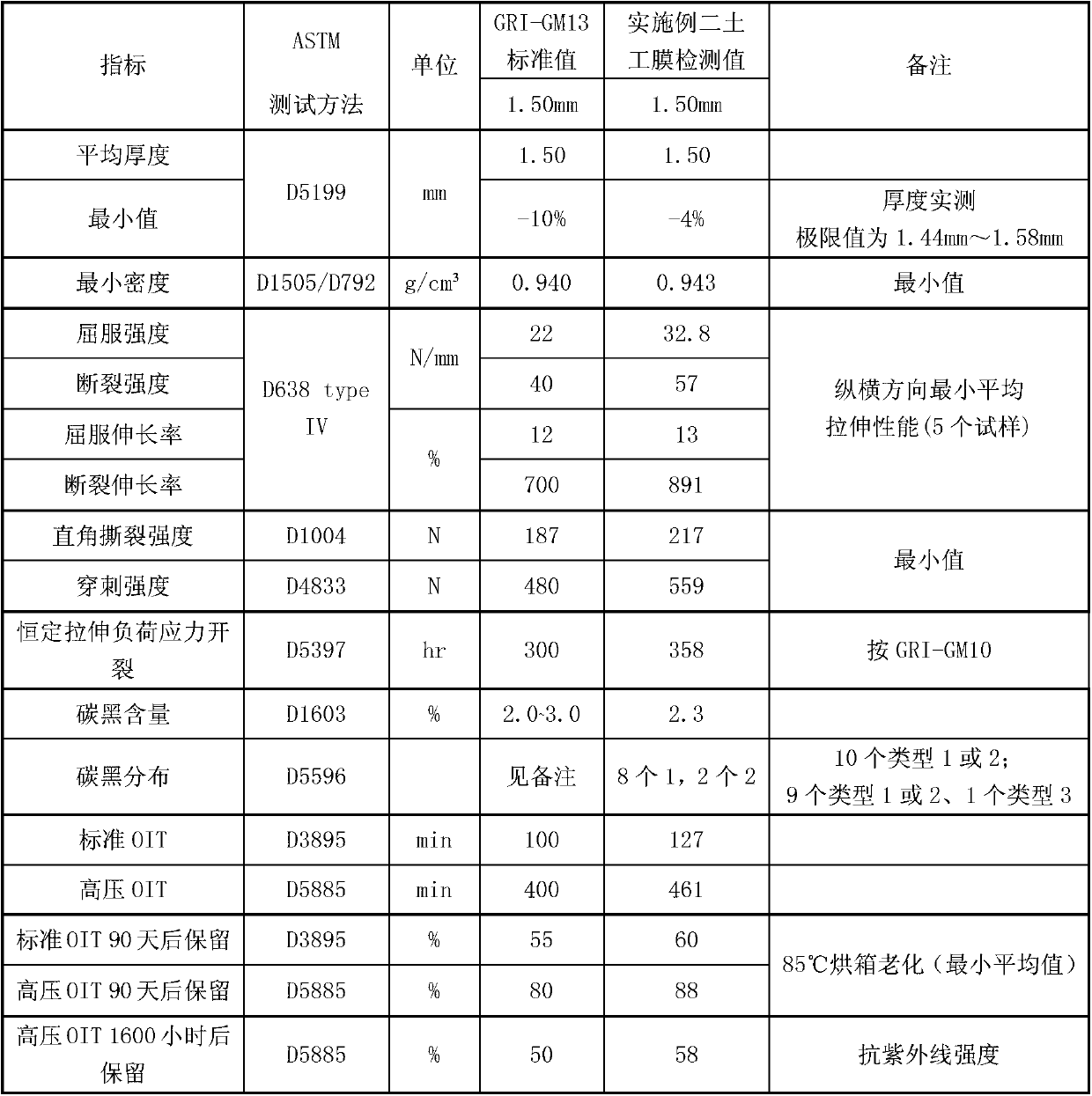

[0031] (1) According to the following formula: the raw material is composed of 100 parts of MDPE and 10 parts of LLDPE; then add the carbon black of 5.4% of the weight of the raw material, the antioxidant of 0.3% of the weight of the raw material, and the light stabilizer of 0.2% of the weight of the raw material. MDPE has a bimodal distribution of molecular weight, butene copolymerization, a comonomer content of about 3%, and a density of 0.936g / cm 3 ~0.938g / cm 3 , Medium density polyethylene with a melt flow rate MFR of 0.1-0.2g / 10min (190°C, 2.16kg). LLDPE is octene copolymer, density 0.920g / cm 3 ~0.925g / cm 3 , Linear low density polyethylene with a melt flow rate MFR of 0.8-1.0g / 10min (190°C, 2.16kg). Carbon black is nano-scale particle size (20-25nm), concentration 45-48%, carrier uses LDPE, density 1.20g / cm 3 ~1.25g / cm 3 , Melt flow rate MFR of 2.0 ~ 2.5g / 10min (190 ℃, 2.16kg) medium pigment carbon black masterbatch, as a UV shielding agent. The antioxidant is 2,6-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com