Reinforced biological stuffing and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

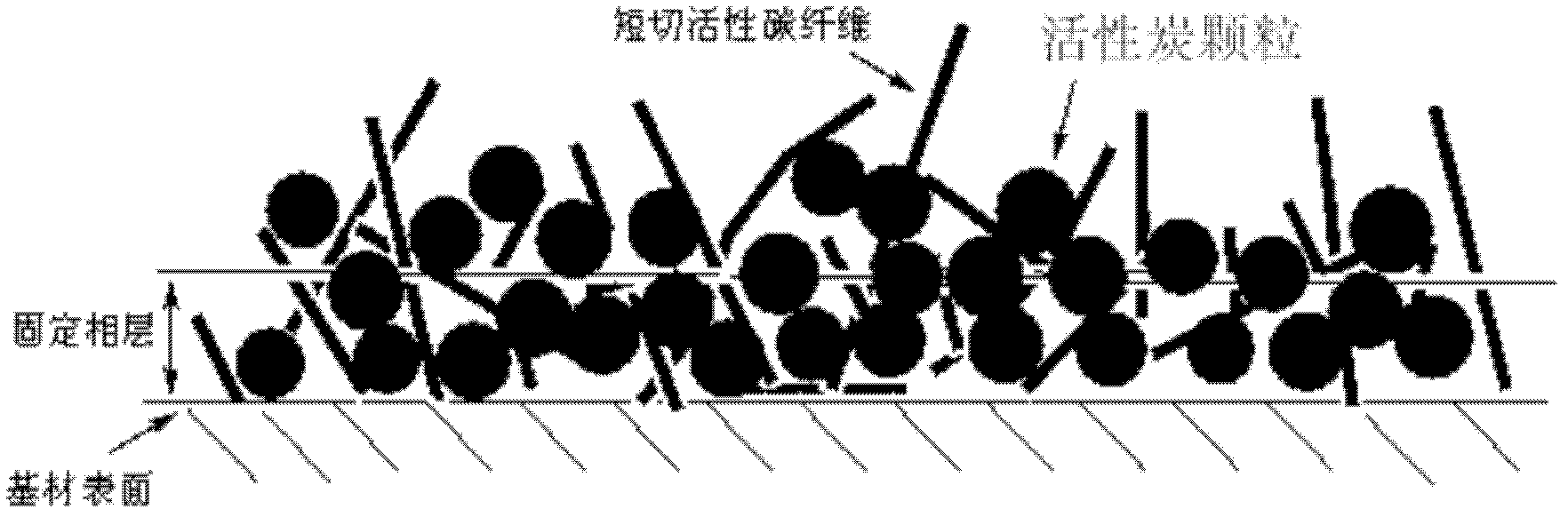

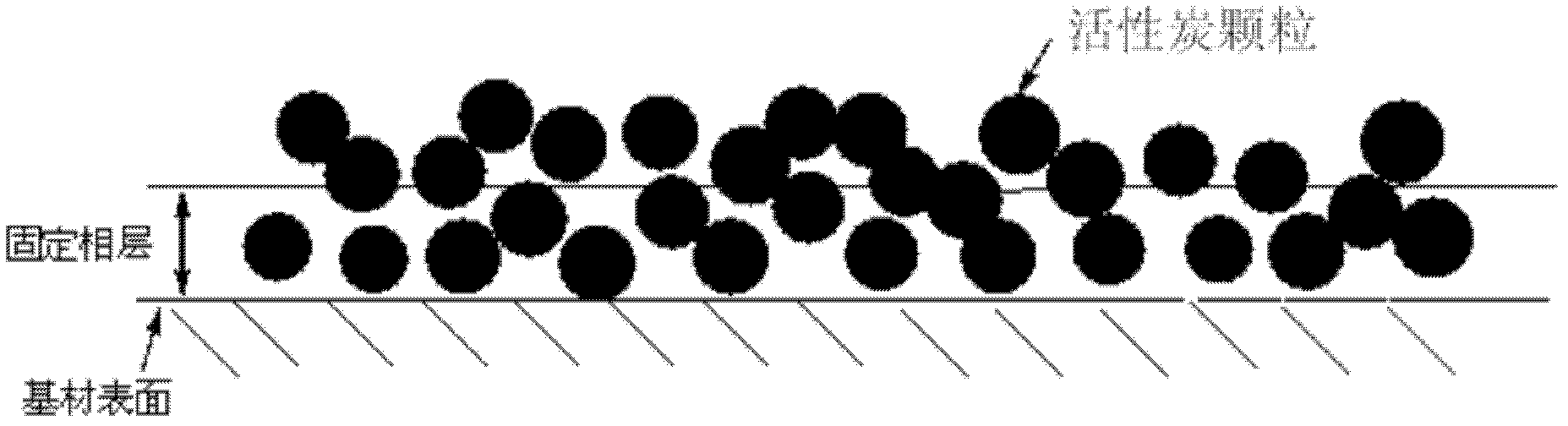

[0018] The invention provides a reinforced biological filler and a preparation method thereof. The enhanced biological filler can overcome the defects that the active carbon is easy to fall off, which causes relatively fast failure and short cycle time. By loading chopped activated carbon fibers and activated carbon particles on the surface of the filler, the specific surface area of the biological filler can be increased, and the structural properties of the two materials can be used to compositely enhance the mechanical properties of the filler, that is, the functional body (high specific surface area) and reinforcement (mechanical properties). The principle is as follows: short-cut activated carbon fibers and activated carbon particles with high specific surface area are selected as reinforcing materials. The former is fibrous and has one-dimensional high tensile strength, and the latter is approximately spherical and has three-dimensional homogeneity. The two materials ...

Embodiment 1

[0069] Example 1 (Preparation and performance characterization of high specific surface polyurethane biofillers with super-hybrid composite reinforcing layer)

[0070] A high specific surface polyurethane biofiller with a super-hybrid composite reinforcement layer was prepared by the following steps.

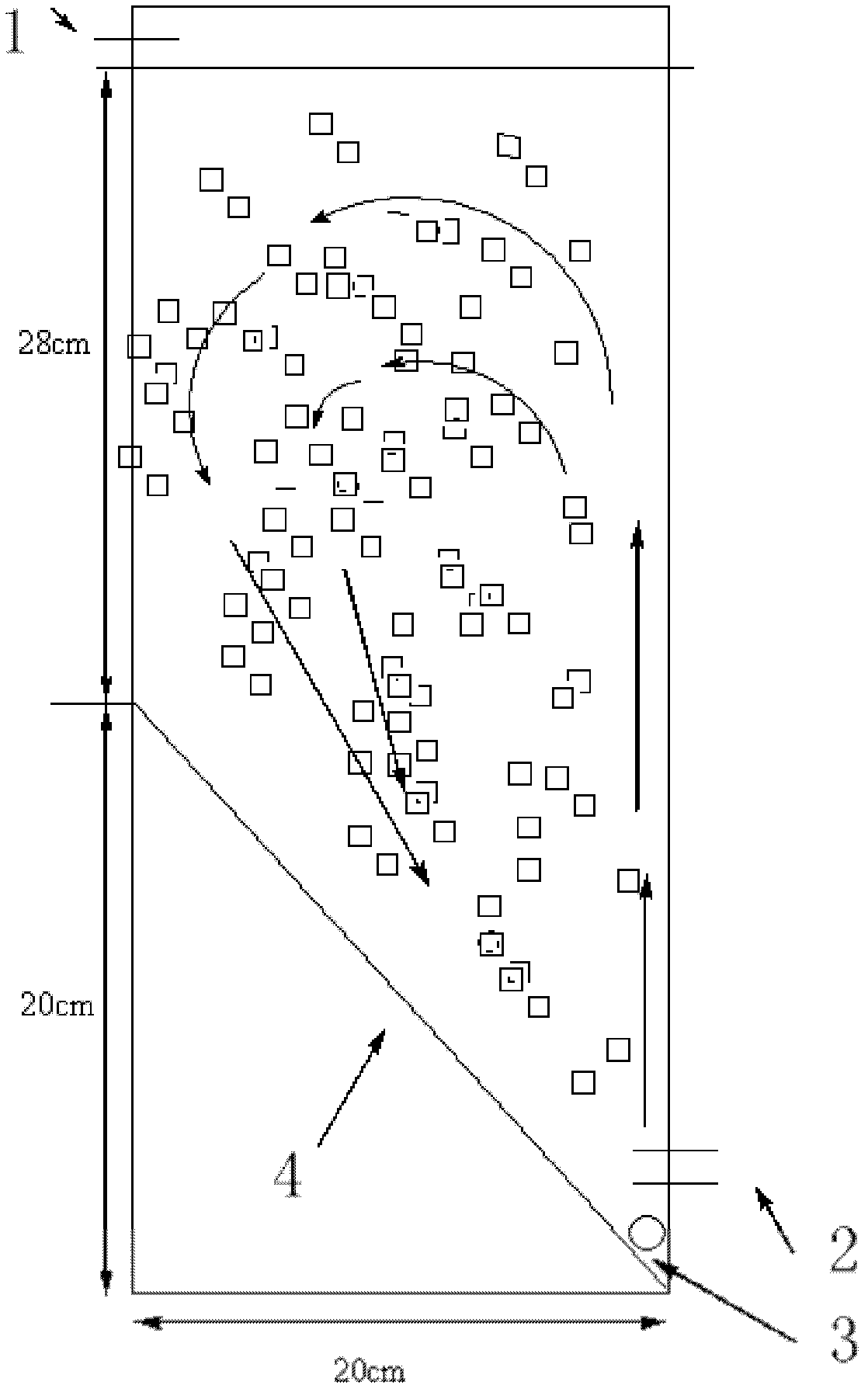

[0071] 1. Activated carbon particles (coconut shell, Beijing Kecheng Guanghua Co., Ltd., powder particle size: 30-80μm, specific surface area about 1000m 2 / g) and chopped activated carbon fiber (STC1300, Jiangsu Sutong Carbon Fiber Co., Ltd., with a diameter of 10-30 μm and a length of 0.05-0.5 mm, namely: Φ(10-30) μm*(50-500) μm, the specific surface area is about 1300m 2 / g) were dried at 120° C. for 4 hours; then 600 g of dried activated carbon particles and 100 g of dried chopped activated carbon fibers were placed in a rotary box (cylindrical, 40 cm in diameter, 100 cm in length, and the rotation speed was 100 rpm), Thoroughly mix by rotating; 10ml nitrifying bacteria ag...

Embodiment 2

[0101] Example 2 (Preparation and performance characterization of high specific surface polyurethane biofillers with super-hybrid composite reinforcing layer)

[0102] Preparation of high specific surface polyurethane biofillers with hyperhybrid composite reinforcement layer by dry method.

[0103] 1. Activated carbon particles (coconut shell, Beijing Kecheng Guanghua Co., Ltd., powder particle size: 30-80μm, specific surface area about 1000m 2 / g) and chopped activated carbon fiber (STC1300, Jiangsu Sutong Carbon Fiber Co., Ltd., with a diameter of 10-30 μm and a length of 0.05-0.5 mm, namely: Φ(10-30) μm*(50-500) μm, the specific surface area is about 1300m 2 / g), were dried at 120°C for 4 hours, and then 600g of dried activated carbon particles and 100g of dried chopped activated carbon fibers were placed in a rotary box (cylindrical, 40cm in diameter, 100cm in length, and the rotation speed was 100rpm) , fully mixed by rotation; with 70 parts by weight of mixed powder, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com