Six-dimensional miniature force and torque sensor used for force feedback of minimally invasive surgical robot

A technology of torque sensor and miniature sensor, which is applied in the direction of instruments, simulators, computer control, etc., can solve the problem of difficult access to contact information, and achieve the effect of easy disassembly and strong biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

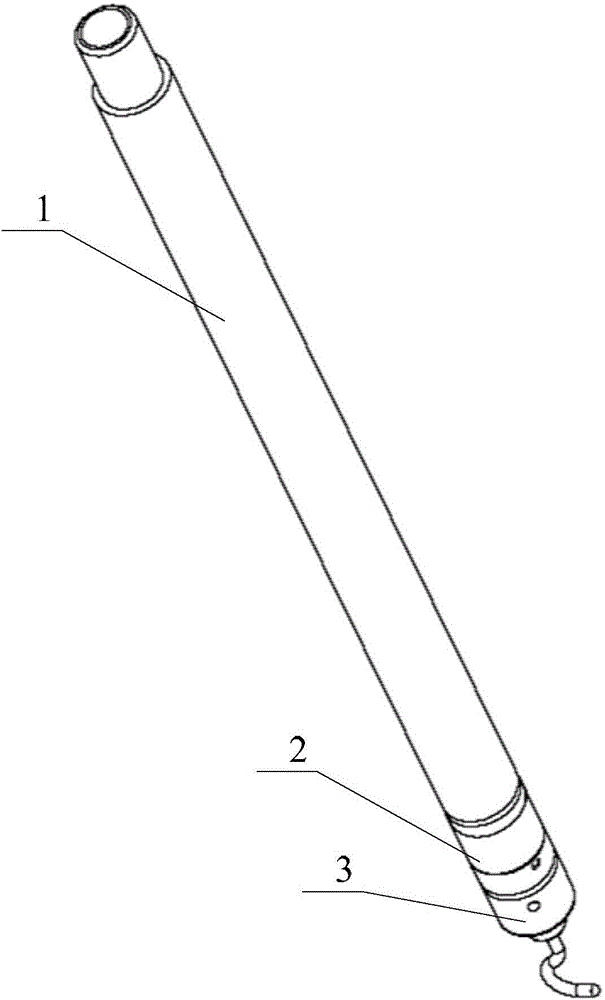

[0025] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the six-dimensional miniature force and torque sensor for minimally invasive surgical robot force feedback described in this embodiment is characterized in that it includes an instrument shaft 1, a miniature sensor 2, a pulling device 3 and a detection circuit 4,

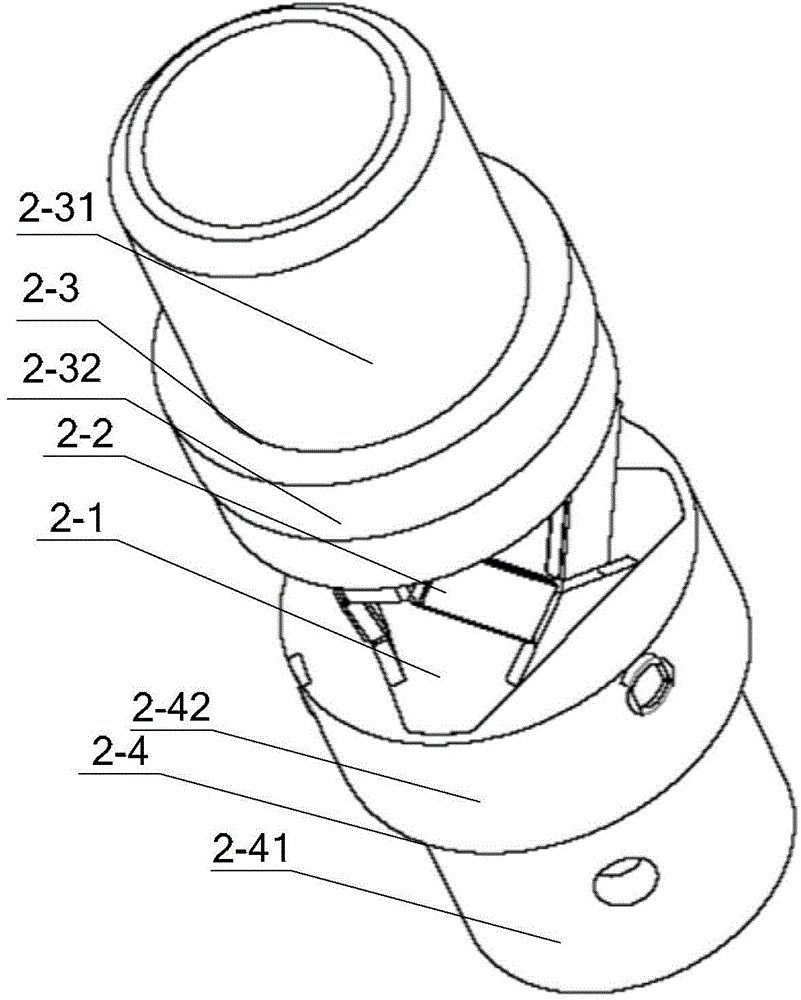

[0026] Miniature sensor 2 is made up of Stewart platform structure elastic body 2-1, twelve strain gauges 2-2, upper connector 2-3, lower connector 2-4 and casing 2-5; Upper connector 2-3 includes The upper connecting ring section 2-31 and the columnar upper support platform 2-32, the lower connecting piece 2-4 includes the lower connecting ring section 2-41 and the columnar lower supporting platform 2-42;

[0027] The pulling device 3 is composed of a sleeve 3-1 and a pull hook 3-2,

[0028] The columnar upper support platform 2-32 is coaxially located at the bottom of the upper connecting ring sectio...

specific Embodiment approach 2

[0034] Specific implementation mode two: the following combination Figure 6 and Figure 7 Describe this embodiment, this embodiment will further explain Embodiment 1, the detection circuit 4 includes a Wheatstone bridge 4-1, a conditioning amplifier circuit 4-2, a six-way analog multiplexer 4-3, a voltage follower 4- 4. Analog-to-digital conversion chips 4-5 and single-chip microcomputers 4-6,

[0035] The voltage signal output end of the strain gauge 2-2 is connected to the signal input end of the Wheatstone bridge 4-1, and the signal output end of the Wheatstone bridge 4-1 is connected to the signal input end of the conditioning amplifier circuit 4-2, and the conditioning amplifier circuit 4 The signal output end of -2 is connected to the signal input end of the six-way analog multiplexer 4-3, the signal output end of the six-way analog multiplexer 4-3 is connected to the signal input end of the voltage follower 4-4, and the voltage follower 4-4 The signal output end of t...

specific Embodiment approach 3

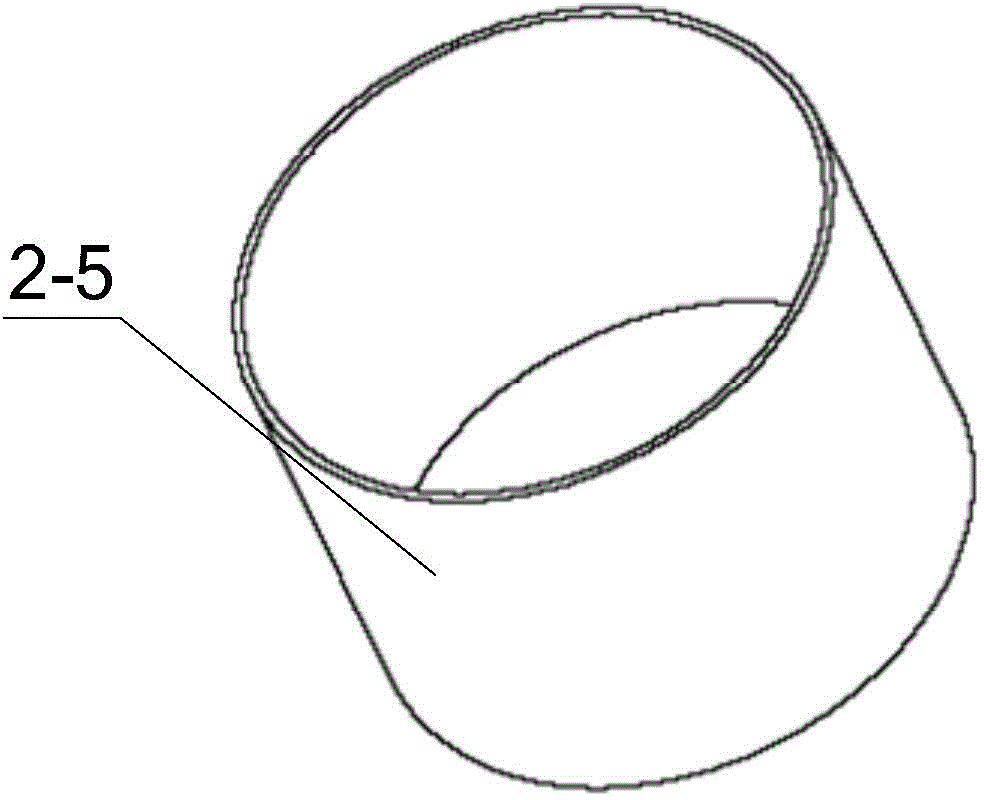

[0039] Specific Embodiment Three: This embodiment will further explain Embodiment One or Two. The top of the casing 2-5 is bonded to the columnar upper support platform 2-32, and the bottom end of the casing 2-5 is bonded to the columnar lower support platform. There is a gap between 2-42.

[0040] In this embodiment, a gap of 0.2 mm may be reserved between the casing 2-5 and the columnar lower support platform 2-42 to provide enough space for the deformation and overload protection of the Stewart platform structure elastic body 2-1.

[0041] The invention can be reliably integrated with multi-degree-of-freedom surgical instruments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com