Aptamer sensor and preparation method thereof

An aptamer sensor and nucleic acid aptamer technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of low sensitivity, complicated testing process, and poor reproducibility, and achieve high sensitivity and selectivity, high preparation efficiency, and detection low limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the preparation method of the aptamer sensor of the present invention, the electrode material for the aptamer sensor is dispersed in ethanol to obtain an electrode material suspension for the aptamer sensor.

[0040] Preferably, the concentration of the electrode material suspension for the aptamer sensor is 1 mg / mL.

[0041] In the preparation method of the aptamer sensor of the present invention, the coating amount of the electrode material suspension for the aptamer sensor on the electrode surface is 5.0 µL.

[0042] In the preparation method of the aptamer sensor of the present invention, the drying time of the modified electrode is 3-8h. The drying temperature is room temperature. The drying temperature can be 20-30°C.

[0043] The water was Milli-Q water (the resistivity at 25°C was 18.2Ω·cm).

[0044] Reagents and materials:

[0045] Nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O), K 3 [Co(CN) 6 ] Purchased from Aladdin Chemical Reagent Co., Ltd. (Shanghai, China). Sodium citrat...

Embodiment 1

[0054] The preparation method of the aptamer sensor of this embodiment includes the following steps:

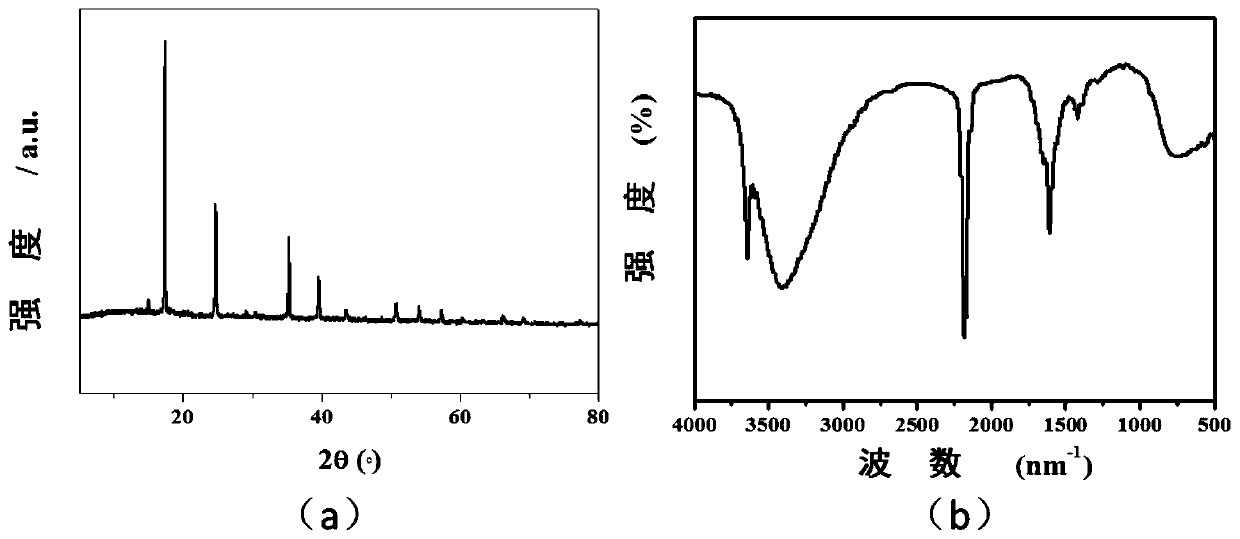

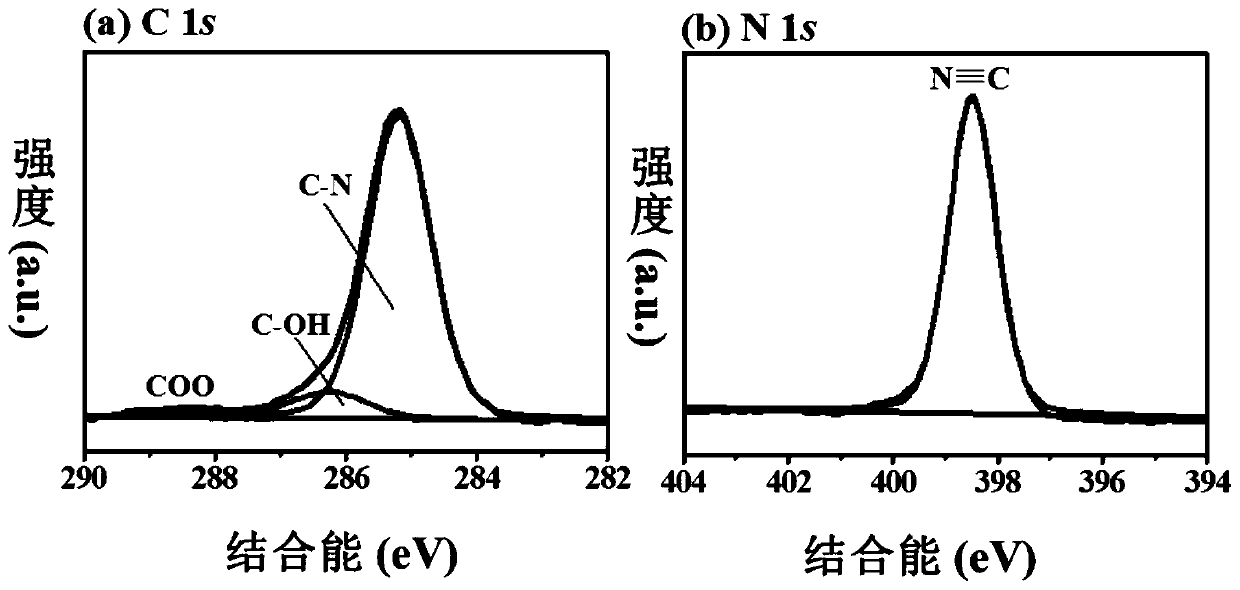

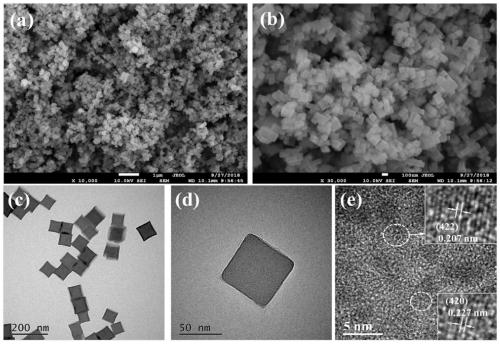

[0055] (1) Preparation of nickel-cobalt Prussian blue analogs

[0056] At room temperature, 0.6 mM (174 mg) of nickel nitrate and 0.6 mM (265 mg) of sodium citrate were dissolved in 20 mL of deionized water to form solution A.

[0057] At room temperature, potassium (III) hexacyanocobaltate (134 mg) was dissolved in 20 mL of deionized water to form solution B.

[0058] At 37°C, while stirring, add solution B to solution A dropwise until a precipitate is formed. The precipitate is separated. The precipitate is washed three times with ethanol, and then dried in a vacuum oven at 60°C for 10 hours to obtain a nickel cobalt Prussian blue analog , Marked as NiCo PBA.

[0059] (2) Pretreatment of bare gold electrode

[0060] First, polish the bare gold electrode with 0.05mm alumina slurry and rinse with ultrapure water.

[0061] Then, in the piranha solution (v / v, H 2 SO 4 : H 2 O 2 = 7: 3) Ri...

Embodiment 2- Embodiment 6

[0070] Example 2-The preparation method of the aptamer sensor of Example 6. The difference from Example 1 is that the concentration of NiCo PBA in step (3) is different, and the rest of the steps are the same as Example 1, Example 1 and Example 2. -The concentration of NiCo PBA in Example 6 is shown in Table 1.

[0071] Table 1 Concentration of NiCo PBA in Example 1 and Example 2-Example 6

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com