Manufacturing method for polymer composite products

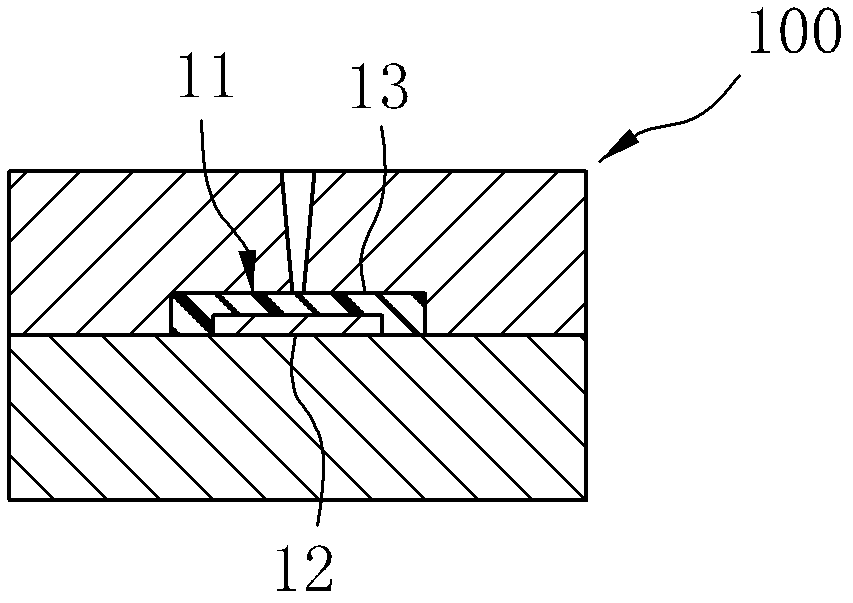

A composite product and manufacturing method technology, applied in the field of product manufacturing, can solve problems such as inability to effectively resist pressure, easy peeling, deformation, etc., and achieve the effect of improving the accuracy of appearance and bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

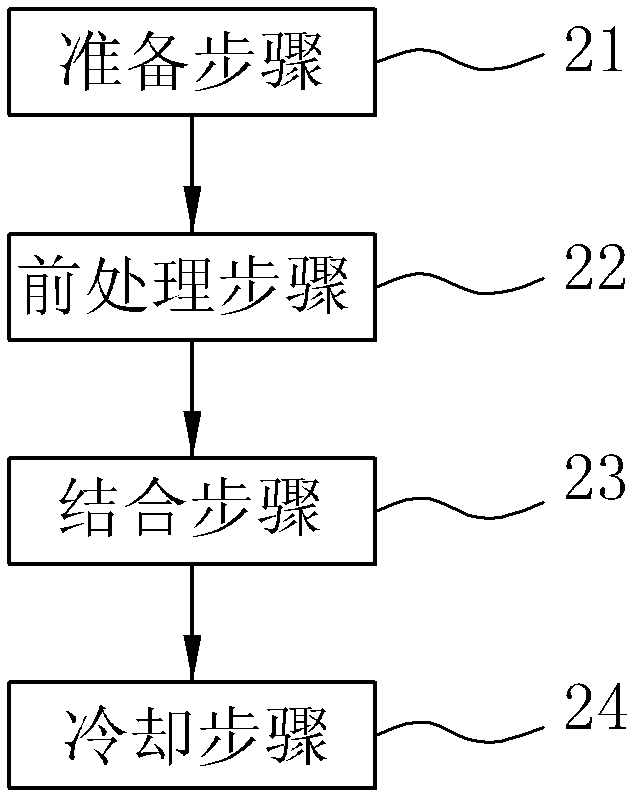

[0026] refer to figure 2 , 3 , The first preferred embodiment of the manufacturing method of the polymer composite product of the present invention includes a preparation step 21 , a pretreatment step 22 , a combining step 23 , and a cooling step 24 .

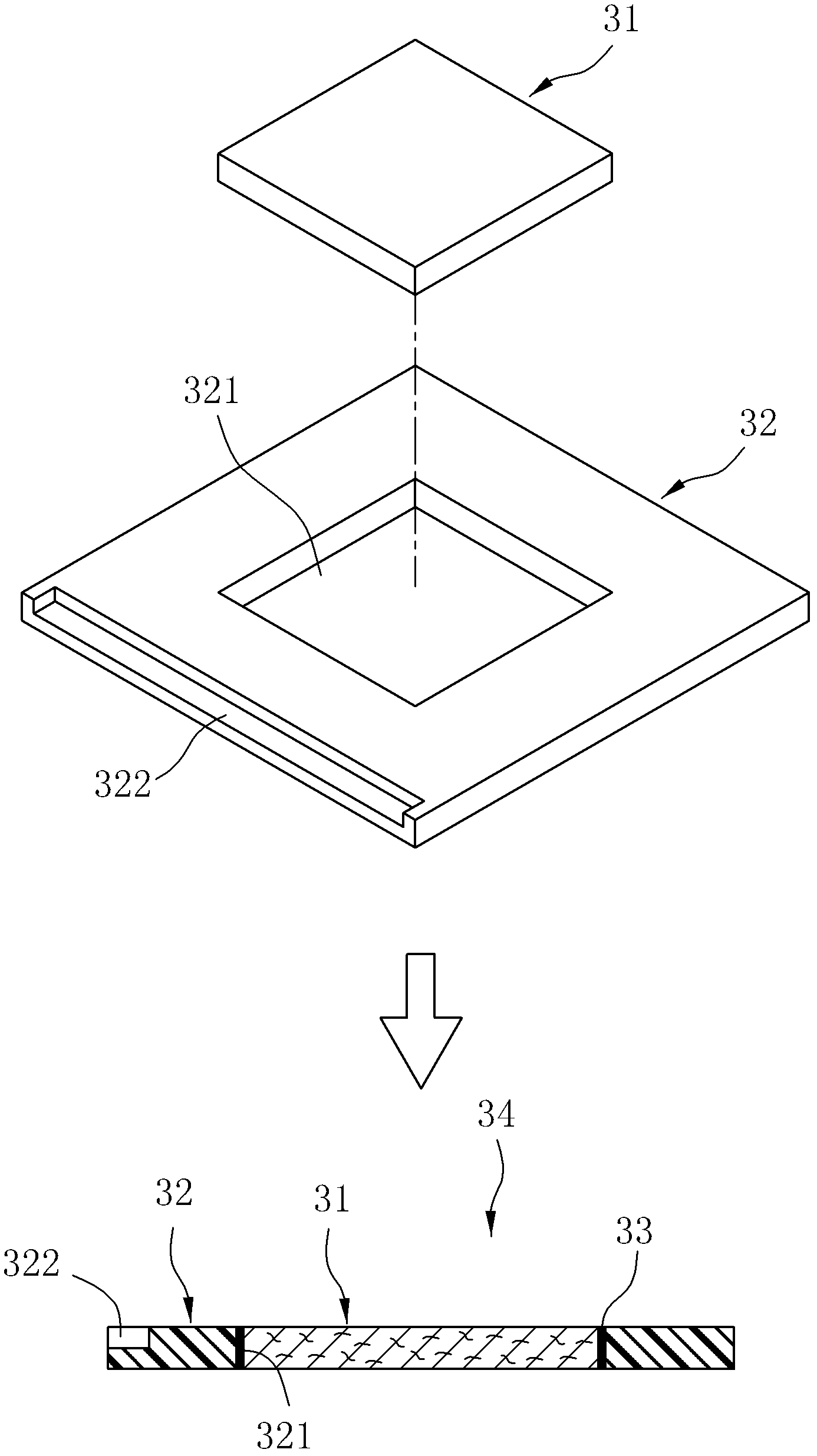

[0027] The preparatory step 21 is to form a semi-finished product 31 with non-polymer materials and polymer materials respectively, and a to-be-processed piece 32 that can match the semi-finished product 31, wherein the semi-finished product 31 is made of fiber-reinforced composite material , the to-be-processed piece 32 has a receiving hole 321 matching the size of the semi-finished product 31, and a structural feature portion 322 in the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com