Realize 150mm high-precision large-stroke tool inching feed and detection device based on ultrasonic motor

An ultrasonic motor and cutting tool technology, applied in feeding devices, manufacturing tools, metal processing machinery parts, etc., to achieve the effect of good start-stop control, high power density, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

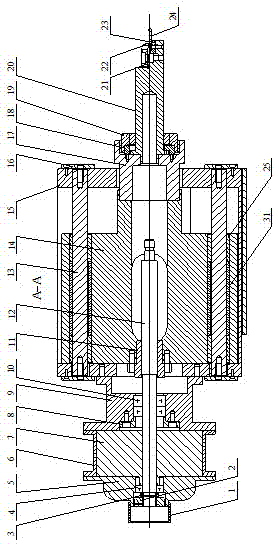

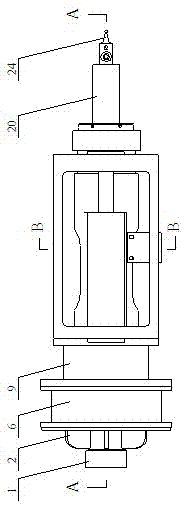

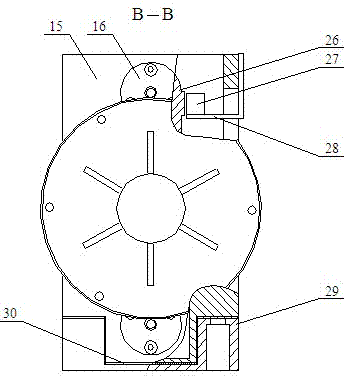

[0015] Such as Figure 1 ~ Figure 3 As shown, this embodiment involves a device based on an ultrasonic motor to realize 150mm high-precision large-stroke tool micro-feeding and detection, including a linear ball guide bush 25, a shaft sleeve 31, a guide rod 13, a sliding block 14, and a tool holder. Frame body 15 and connecting flange one 16, the front and rear ends of described guide rod 13 are fixed on the knife rest frame body 15, are connected by connecting flange one 16 between guide rod 13 and knife rest frame body 15, slide block 14 is arranged in the frame body 15 of the tool holder, and linear ball guide bushings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com