Method for preparing spherical cobalt powder

A cobalt powder and spherical technology, which is applied in the field of preparing spherical cobalt powder and raw material cobalt powder, can solve the problems of low purity of spherical cobalt powder, unfavorable industrial production, difficult operation and realization, etc., and achieves controllable product particle size and good reliability The effect of mixing and good shape characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

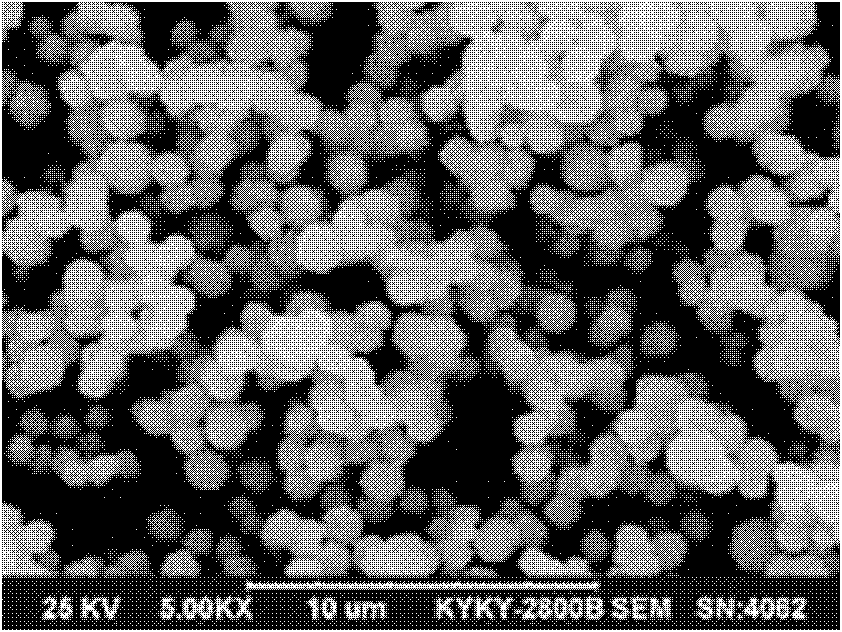

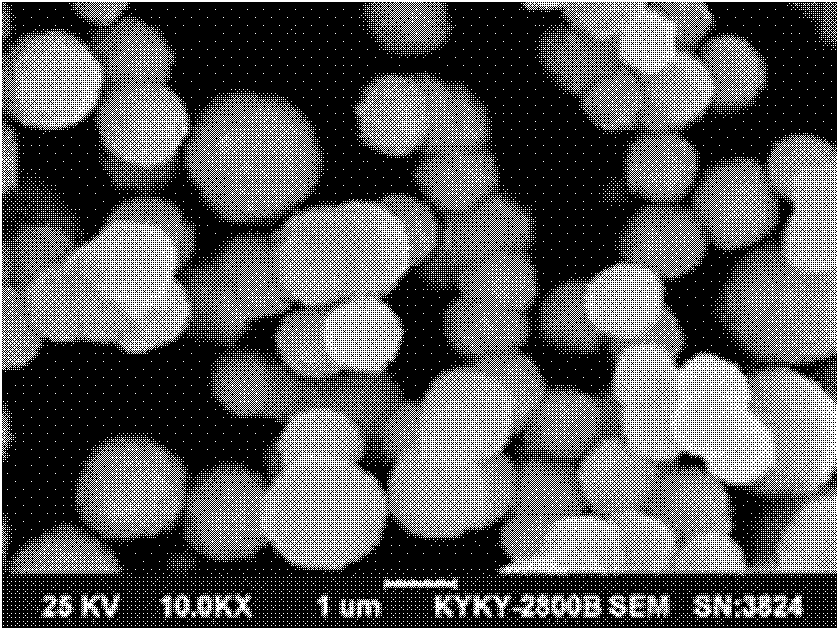

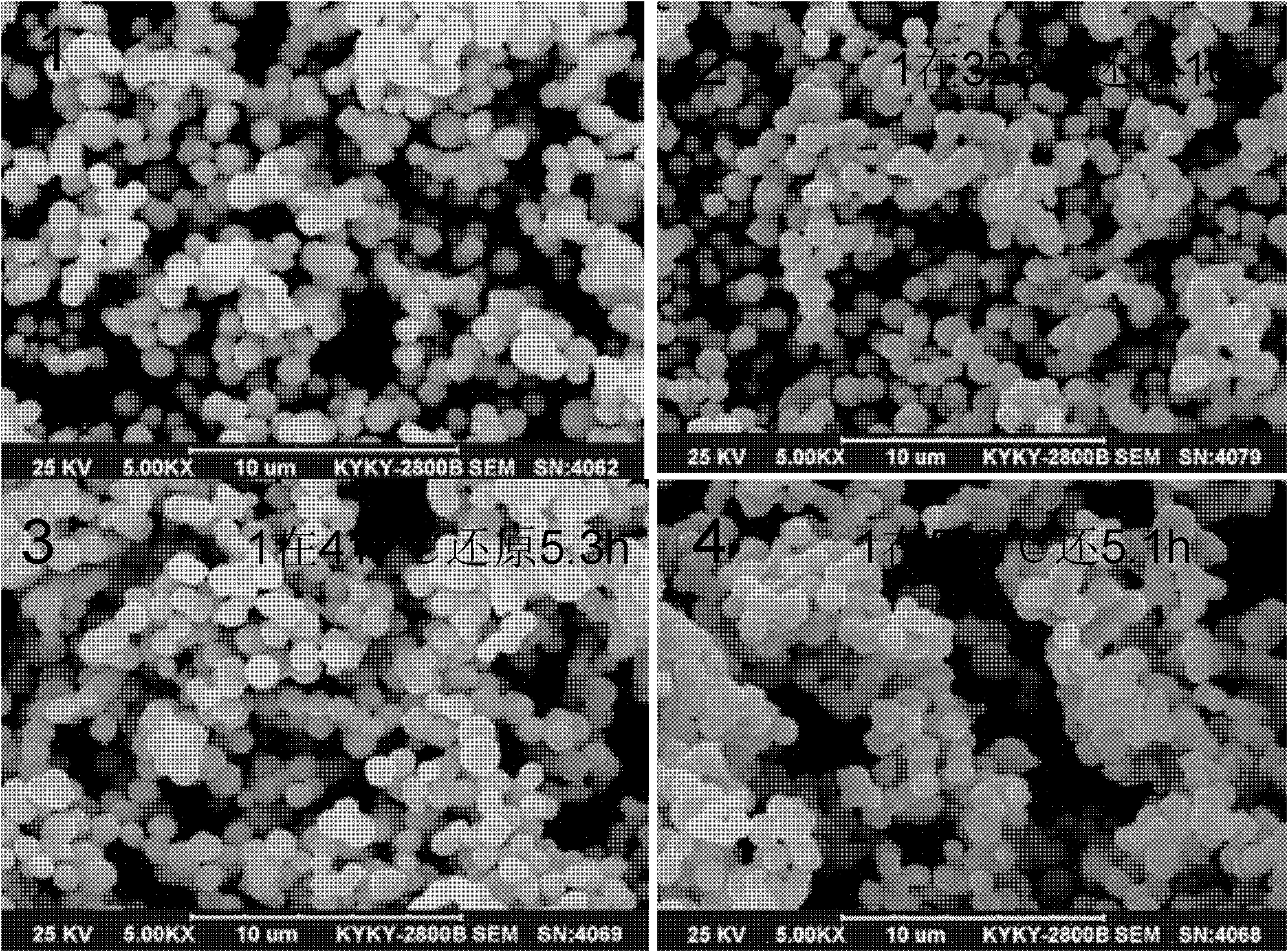

[0022] A method for preparing spherical cobalt powder, comprising the steps of: taking CoCl 2 ·6H 2 Mix O with ethylene glycol, add NaOH solution, n(NaOH):n(Co)=4, prepare a mixed solution, wherein the concentration of cobalt is 30g / L, the concentration of ethylene glycol is 80g / L, heat to 198°C, Reflux for 2 hours, suction filtration, washing, hydrogen drying and reduction in four stages of high temperature, the temperature of each stage is: 416°C, 420°C, 426°C and 415°C, and the flow rate of hydrogen is 4m 3 / h, the process also adds a flow rate of 6m 3 / h of nitrogen for 4 hours to obtain spherical cobalt powder.

[0023] The spherical cobalt powder prepared by the invention has an average particle size of 1-10 μm, a spherical shape, uniform distribution and a purity of 99.96%.

Embodiment 2

[0025] A method for preparing spherical cobalt powder, comprising the steps of: taking CoCl 2 ·6H 2 O is mixed with ethylene glycol, NaOH solution is added, n(NaOH):n(Co)=8, Prepare a mixed solution, in which the concentration of cobalt is 28g / L, the concentration of ethylene glycol is 60g / L, heated to 197°C, refluxed for 3 hours, suction filtered, washed, dried and reduced by hydrogen in four stages of high temperature, and the temperature of each stage is respectively : 310°C, 317°C, 317°C and 310°C, the flow rate of hydrogen is 4m 3 / h, nitrogen flow rate is 64m 3 / h for 12 hours to obtain spherical cobalt powder.

[0026] The spherical cobalt powder prepared by the invention has an average particle size of 1-10 μm, a spherical shape, uniform distribution and a purity of 99.95%.

Embodiment 3

[0028] A method for preparing spherical cobalt powder, comprising the steps of: taking CoCl 2 ·6H 2 O is mixed with ethylene glycol, NaOH solution is added, n(NaOH):n(Co)=1, Prepare a mixed solution, in which the concentration of cobalt is 10g / L, the concentration of ethylene glycol is 40g / L, heat to 196°C, reflux for 4 hours, filter with suction, wash, dry and reduce at 500°C with mixed gas of hydrogen and nitrogen for 6h , to obtain spherical cobalt powder.

[0029] The spherical cobalt powder prepared by the invention has an average particle size of 1-10 μm, a spherical shape, uniform distribution and a purity of 99.96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com