Sonochemistry preparing method of nitrogen and rare earth element codope nanometer titania crystal

A nano-titanium dioxide, rare earth element technology, applied in the chemical/physical/physical chemical process of energy application, microsphere preparation, microcapsule preparation, etc., can solve the problems of high time consumption, inseparable from high temperature treatment, high energy consumption, etc. , to achieve the effect of simple process, narrow particle size distribution and small product particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

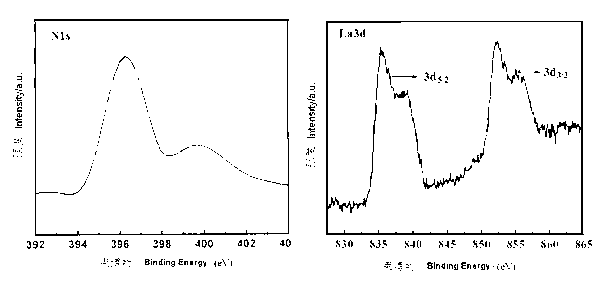

Image

Examples

Embodiment 1

[0029] Dissolve 5ml tetraisopropyl titanate into 30ml deionized water / isopropanol (1:3, volume ratio) mixture to obtain solution A. 0.2 g urea, 0.3 g La (NO 3 ) 3 Dissolve in 20ml of deionized water / isopropanol (1:1, volume ratio) mixture to obtain solution B. Then the solution is slowly added dropwise to solution A, and at the same time, the titanium alloy probe of the ultrasonic generator is immersed in it for ultrasonic treatment. The ultrasonic frequency is 40KHz and the intensity is 60W / cm 2 , control the temperature of the reaction solution at 90°C, and the reaction time is 3h, then add 0.1g of polypyrrolidone dispersant, stir for 1h with magnetic force, then centrifuge, and the obtained precipitates are washed twice with deionized water and once with absolute ethanol, and finally vacuum-dried . The obtained product is short columnar, with a size of 10 / 16nm (W / L), narrow particle size distribution range, good monodispersity, and anatase crystal form.

Embodiment 2

[0031] Dissolve 5ml of tetrabutyl titanate into 30ml of deionized water / ethanol (1:3, volume ratio) mixture to obtain solution A. 0.2g urea, 0.3gCe(NO 3 ) 3 Dissolve in 20ml of deionized water / ethanol (1:1, volume ratio) mixture to obtain solution B. Then, while sonicating, solution B was slowly added dropwise into solution A. Ultrasonic frequency is 100KHz, intensity is 35 W / cm 2 , control the temperature of the reaction solution at 70°C, and the reaction time is 4 hours, then add 0.1g of polyethylene glycol (PEG) dispersant, stir it magnetically for 1 hour, then centrifuge, and the obtained precipitates are washed twice with deionized water and absolute ethanol Once, and finally vacuum dry. The obtained product is short columnar, with a size of 9 / 14nm (W / L), narrow particle size distribution range, good monodispersity, and anatase crystal form.

Embodiment 3

[0033] Dissolve 5ml of tetrapropyl titanate into 30ml of deionized water / propanol (1:3, volume ratio) mixture to obtain solution A. 0.2g (NH 4 ) 2 SO 4 , 0.3gNd(NO 3 ) 3 Dissolve in 20ml of deionized water / isopropanol (1:1, volume ratio) mixture to obtain solution B. Then solution B was slowly added dropwise to solution A while ultrasonic treatment was performed. Ultrasonic frequency is 20KHz, intensity is 40W / cm 2 , control the temperature of the reaction solution at 80°C, and the reaction time is 4h, then add 0.1g of polypyrrolidone dispersant, stir it with magnetic force for 1h, then centrifuge, and the obtained precipitates are washed twice with deionized water and once with absolute ethanol, and finally vacuum-dried . The obtained product is short columnar, with a size of 12 / 19nm (W / L), narrow particle size distribution range, good monodispersity, and anatase crystal form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com