Temperature gradient liquid-liquid-liquid microextraction method

A temperature gradient and extraction technology, applied in liquid solution solvent extraction and other directions, can solve the problems of long extraction time and low absolute recovery rate, and achieve the effects of improving extraction recovery rate, simple operation and improving extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

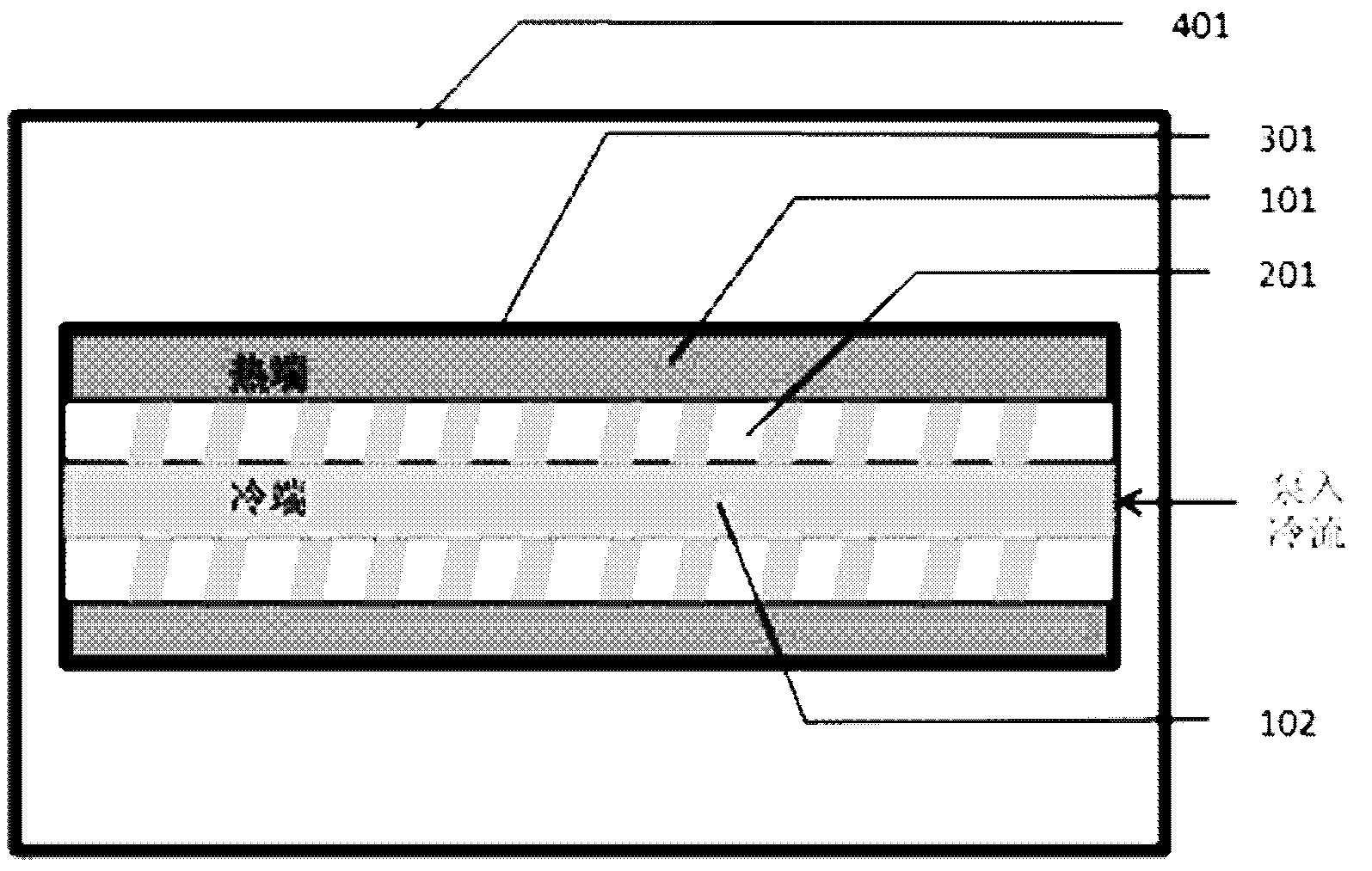

[0030] Embodiment 1: with figure 1 The extraction device shown realizes the extraction and enrichment of gibberellin GA3 in water

[0031] 1) Extraction device: This device is connected by a tee and a thin tube to form a shell-and-tube channel. Cut the polyvinylidene fluoride hollow fiber membrane that has been ultrasonically dried with acetone into 9 cm sections (the inner diameter of the membrane is 800 μm, the wall thickness is 200 μm, and the pore size is 0.2 μm). The coaxial structure is realized by the nesting of the inner tube and the outer tube. The inner tube is a hollow fiber membrane, and the outer tube is made of metal, inorganic material or polymer material, with a diameter of 1.3mm. The two ends of the outer tube are connected and sealed with the tee, and the hollow fiber membrane passes through the inner channel of the tee. lead out at one end. The receiving phase is imported and exported from the C terminals of the two tees.

[0032] 2) Provide phase confi...

Embodiment 2

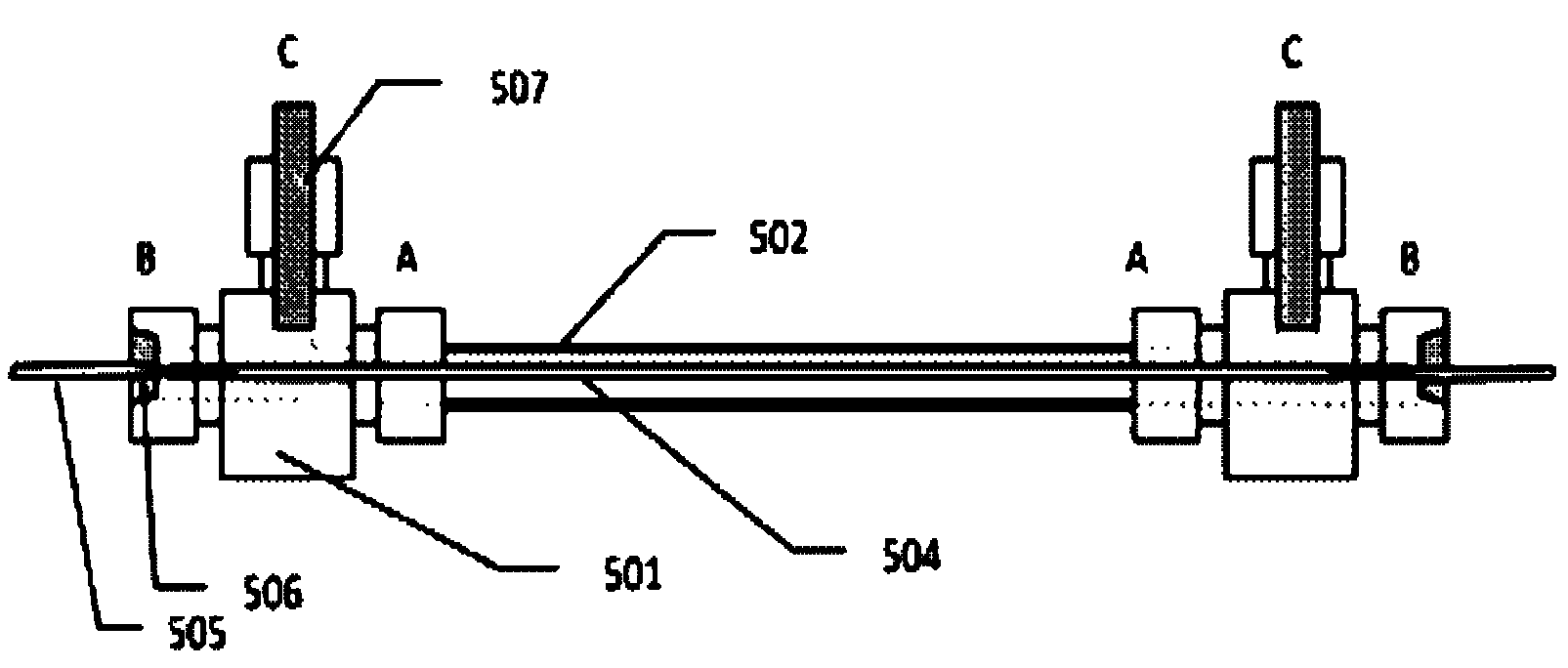

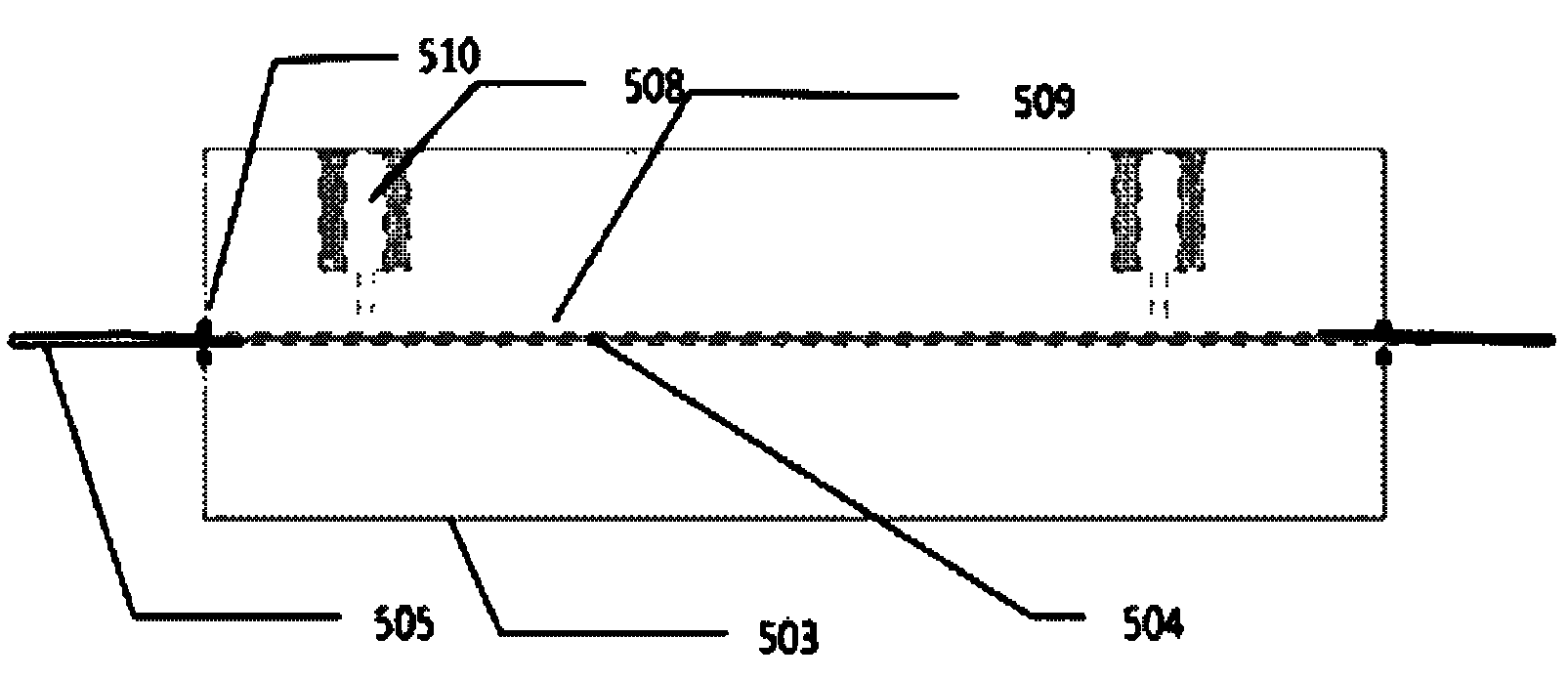

[0038] Embodiment 2: with figure 2 The extraction device shown realizes the extraction and enrichment of gibberellins GA1, GA3, and GA4 in water

[0039] 1) Extraction device: This device processes a shell-and-tube channel from a single piece of material. Cut the polypropylene hollow fiber membrane that has been ultrasonically dried with acetone into 9 cm sections (the inner diameter of the membrane is 600 μm, the wall thickness is 200 μm, and the pore diameter is 0.2 μm), and the dried membrane is passed through the AB end of the 1.05 mm diameter channel processed by PMMA material , and the gap between the AB end of the channel and the hollow fiber membrane is sealed with epoxy glue, and the two ends of the hollow fiber membrane are respectively connected with a stainless steel tube with an outer diameter of 0.6 mm and heated and sealed.

[0040] 2) Provide phase configuration: Dissolve GA1, GA3, and GA4 mixed standard samples in acetonitrile to obtain a 100 μg / mL stock sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com