Optical axis and thickness measurement method and device of differential confocal internal-focusing lens

A differential confocal and thickness measurement technology, which is applied in the direction of measuring devices, using optical devices, testing optical properties, etc., to achieve high axial resolution, reduce running distance, and increase depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

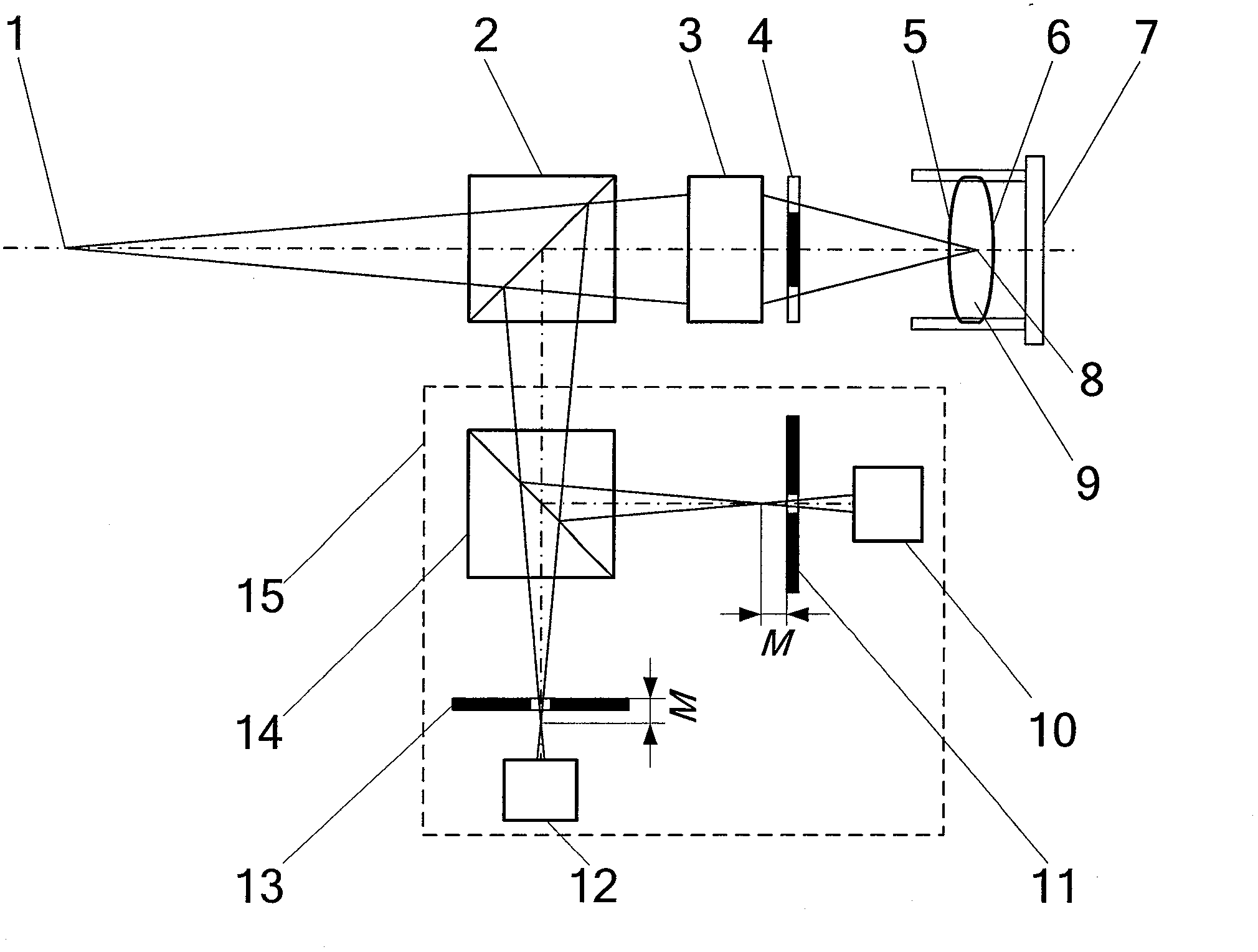

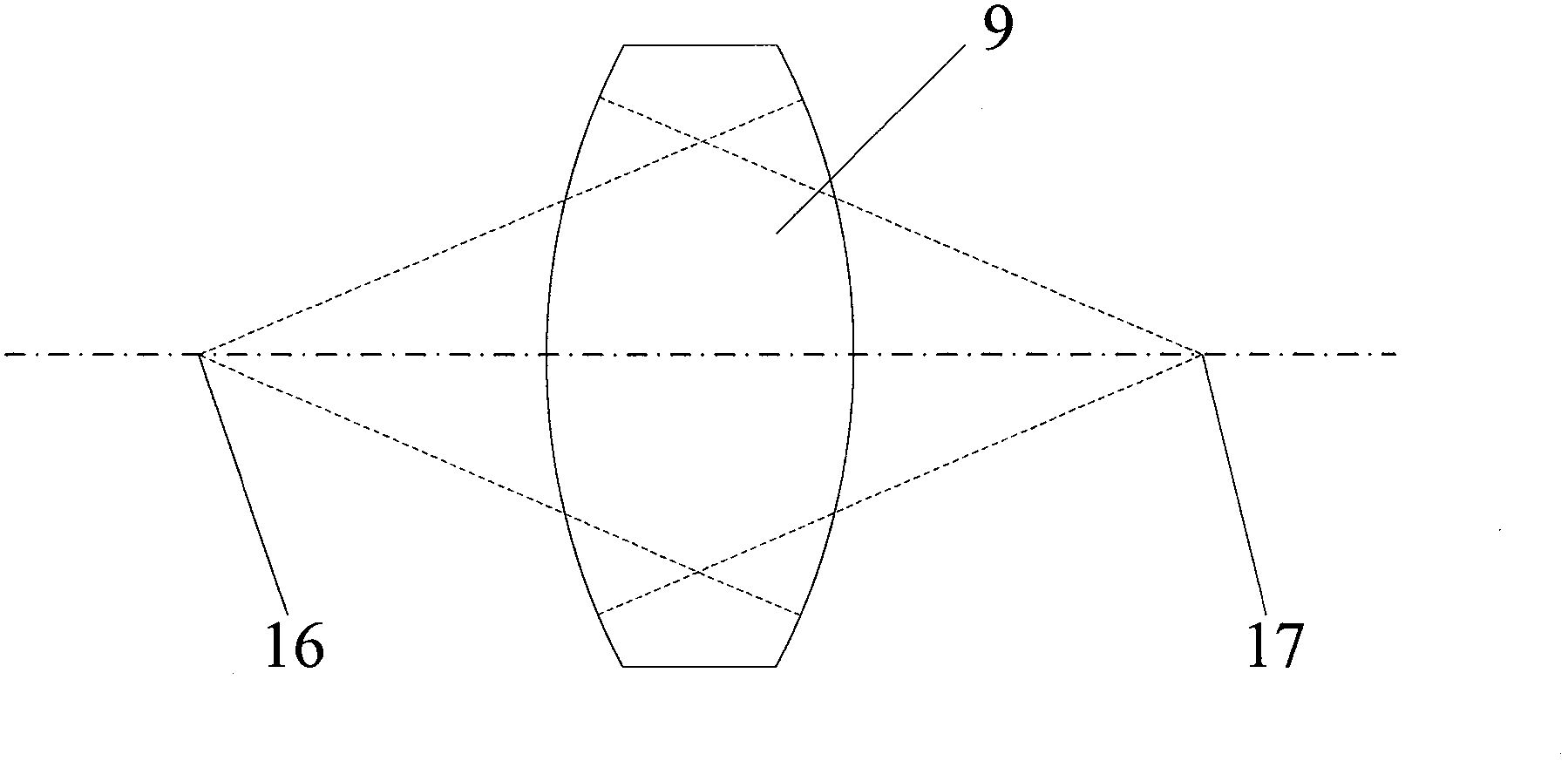

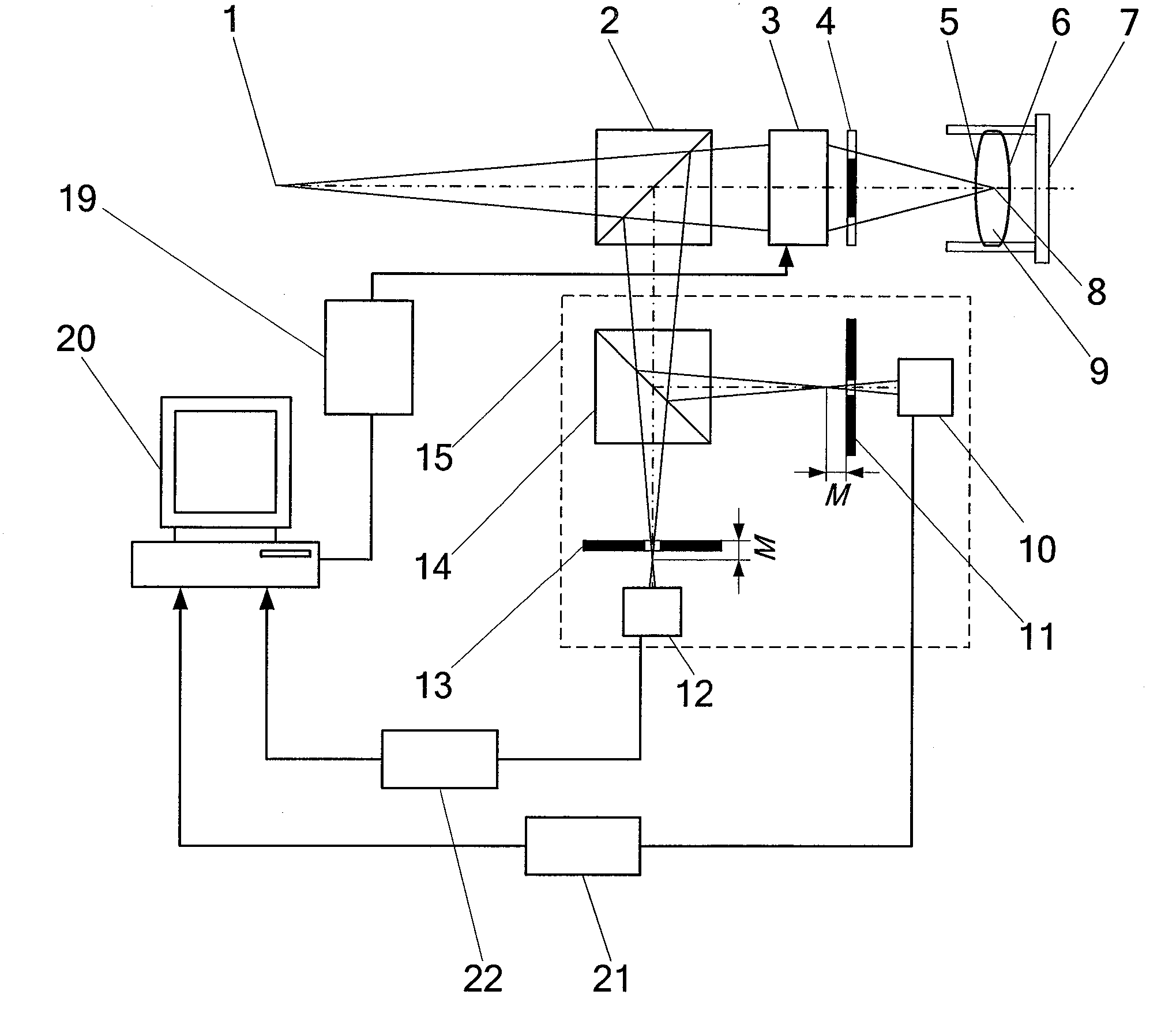

[0057] like Figure 7 As shown, the optical axis and thickness measuring device of the differential confocal inner focusing method lens includes a point light source generating device 18, which is sequentially placed in the first beam splitter 2, the inner focusing objective lens 3 and the ring light in the direction of the light emitted by the point light source 1. Pupil 4 also includes a differential confocal system 15 placed in the reflection direction of the first beam splitter 2, wherein the surface of the measured lens 9 and the first beam splitter 2 reflect the light beam to the second beam splitter in the differential confocal system 15 14; the second beam splitter 14 divides the light into two paths, the reflected light illuminates the CCD detector 30 after passing through the pinhole 11 after the focus, and the transmitted light illuminates the CCD detector 31 after passing through the pinhole 13 before the focus; the image acquisition card 32 collects the CCD detecti...

Embodiment 2

[0074] like Figure 4 and Figure 7 As shown, the embodiment 1 Figure 7 The differential confocal system in 15 is replaced by Figure 4 The differential confocal system 15 can constitute the second embodiment. The difference from Embodiment 1 is that after the light enters the differential confocal system 15 , the second beam splitter 14 splits the light into two paths, the reflected light illuminates the first light intensity sensor 10 , and the transmitted light illuminates the second light intensity sensor 12 . All the other measuring methods and devices are the same as in Example 1.

Embodiment 3

[0076] like Image 6 and Figure 7 As shown, the embodiment 1 Figure 7 The differential confocal system in 15 is replaced by Image 6 The differential confocal system 15 can constitute Embodiment 3. The difference from Embodiment 1 is that after the light enters the differential confocal system 15, the second beam splitter 14 divides the light into two paths, and the reflected light forms an image on the surface of the first light intensity sensor 10 after passing through the focused microscopic objective lens 23. The transmitted light is imaged on the surface of the second light intensity sensor 12 after passing through the pre-focus microscopic objective lens 24; wherein the object plane of the post-focus microscopic objective lens 23 is positioned after the focus, and the first light intensity sensor 10 is placed on its image plane, and the pre-focus microscopic The object plane of the objective lens 24 is located in front of the focus, and the second light intensity se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com