Nano composite quaternary phosphonium salt resin

A nano-composite, quaternary phosphonium salt technology, applied in the direction of organic compound/hydride/coordination complex catalysts, organic chemistry, physical/chemical process catalysts, etc., can solve the problem of rapid activity decline, low catalyst activity, easy resin swelling, etc. problem, to achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

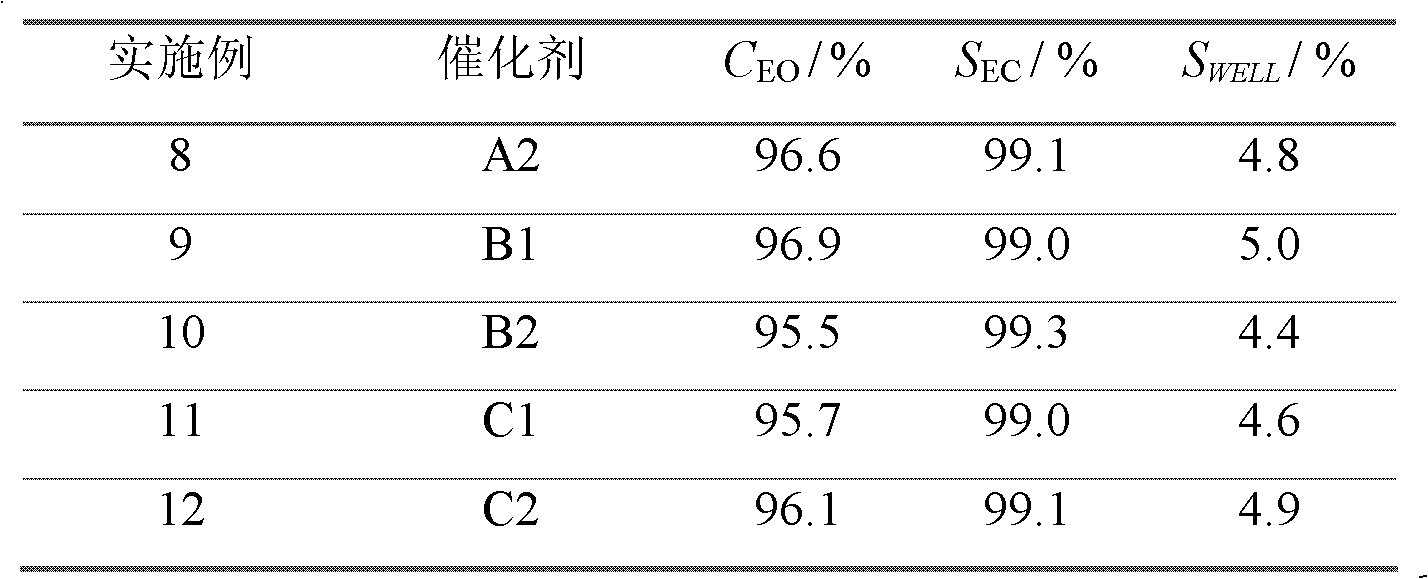

Examples

Embodiment 1

[0022] Add 58.0 grams of styrene, 0.6 grams of divinylbenzene, 30 grams of polystyrene and 0.6 grams of benzoyl peroxide initiator in a 500 milliliter three-necked flask, and stir for 2.0 hours at 60°C; then add 2.8 grams of multi-walled carbon Nanotubes, continue stirring for 1 hour for pre-polymerization. 260 mL of deionized water in which 2.5 g of polyvinyl alcohol had been dissolved was added. Adjust the stirring speed while gradually raising the temperature to 80°C and react for 5 hours; then raise the temperature to 90°C and react for 5 hours; finally raise the temperature to 98°C and react for 6 hours. After the reaction, pour out the upper liquid, wash with 85°C hot water, then wash with cold water, then filter, put in an oven to dry at 80°C, sieve, and collect composite microspheres with a particle size within the range of 0.35 to 0.60 mm a.

[0023] Chloromethylation of composite microspheres: In a 500-ml three-necked flask, add 50 grams of composite microspheres A...

Embodiment 2

[0026] In a 500 ml three-necked flask, add 20 grams of the composite chlorine ball A obtained in [Example 1], 150 milliliters of benzonitrile, 35.0 grams of dimethylphenylphosphine and 10.0 grams of nickel bromide, and stir and react under reflux for 30 hours After the reaction, the mother liquor was removed by filtration, washed with dichloromethane, acetone and water successively, and dried under vacuum to obtain the nanocomposite quaternary phosphonium salt resin A2.

Embodiment 3

[0028] Add monomer mixture solution (60.0 gram styrene, 1.7 gram divinylbenzene, 60 gram polystyrene, 1.6 gram multi-walled carbon nanotube and 1.0 gram benzoyl peroxide containing initiator in 500 milliliters of three-necked flasks, The solution was first stirred and reacted at 70°C for 0.5 hours), started the agitator, added a mixed solution of 200 milliliters of deionized water and 5 grams of gelatin, raised the temperature to 85°C, reacted for 3 hours, then raised the temperature to 90°C, reacted for 9 hours, and finally The temperature was raised to 100° C., and the reaction was carried out for 10 hours. After the reaction, pour out the upper liquid, wash with 85°C hot water, then wash with cold water, then filter, put in an oven to dry at 80°C, sieve, and collect composite microspheres with a particle size within the range of 0.35 to 0.60 mm b.

[0029] Chloromethylation of composite microspheres: In a 500-ml three-necked flask, add 50 grams of composite microspheres B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com