Super duplex stainless steel ingot hot working cogging method

A duplex stainless steel and production method technology, applied in the field of metallurgy, can solve the problems of high metallurgical manufacturing cost, low metal billet rate, and long production cycle, and achieve the effects of reduced metallurgical manufacturing cost, simple process, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

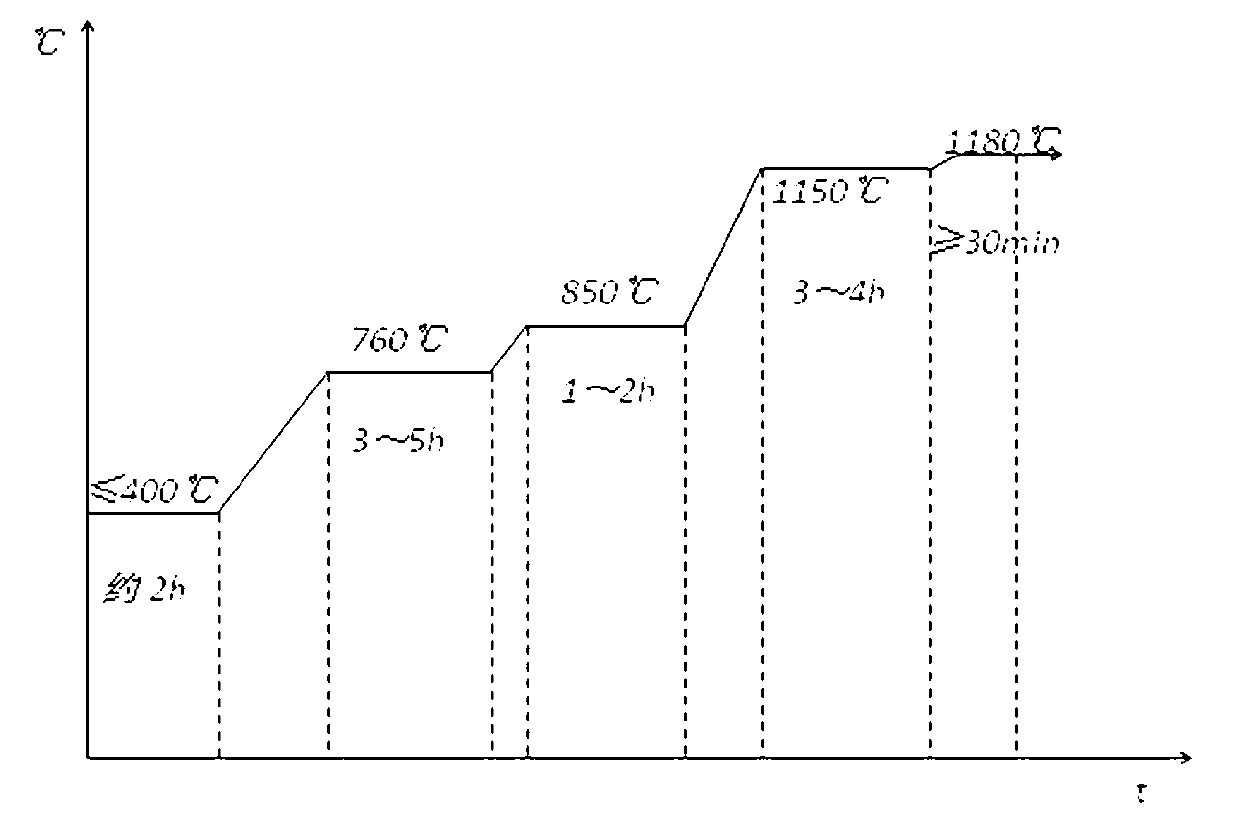

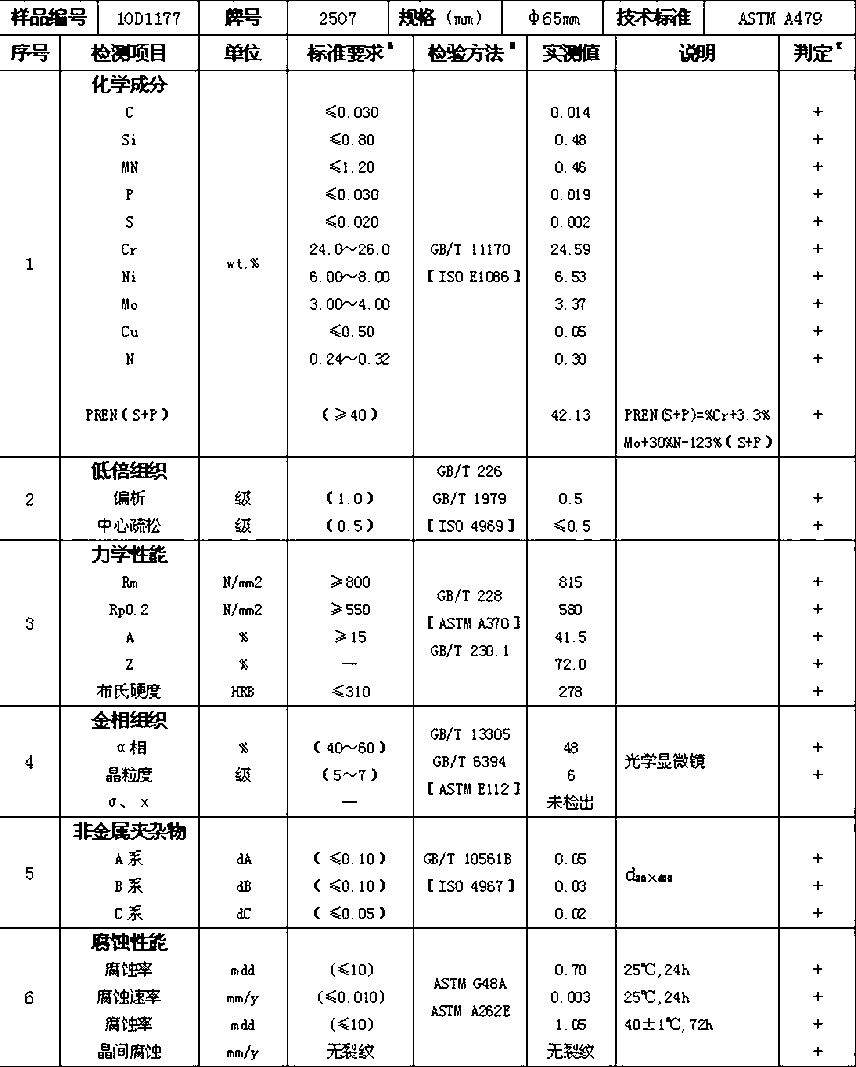

[0025] A production method for hot-processing billeting of super duplex stainless steel ingots, using bell-type electric soaking furnace to heat steel ingots (ingot weight 0.75 tons) + preliminary rolling mill (850 rolling mill) for thermal processing billeting, and producing 2507 square meters Billet (140×140×5000mm).

[0026] During the first fire rolling of the blooming mill, the soaking furnace heats the steel ingot: (A) the furnace temperature of the steel ingot is ≤400°C, and the temperature is kept for 1.5 hours; (B) the temperature is raised to 760°C at a speed of 60°C / h for 3 hours, and Raise the temperature to 850°C and hold it for 1 hour; (C) raise the temperature to 1150°C at a rate of 80°C / h, turn over the steel ingot after holding it for 2 hours, and keep it for 1 hour; (D) heat it up to 1180°C at a rate of 100°C / h ℃, heat preservation ≥ 30 minutes, enter the blooming mill for the first fire rolling.

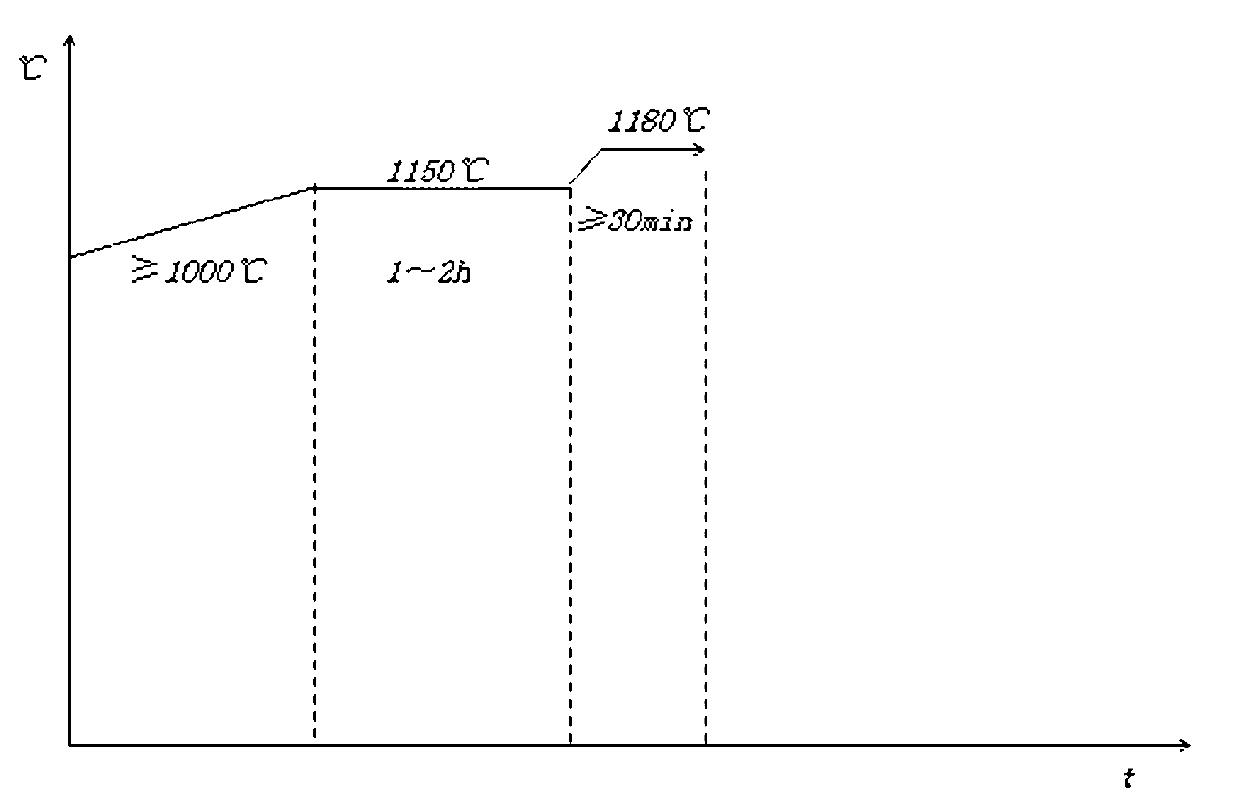

[0027] Hot processing blanking of the blooming mill: (A) Bef...

Embodiment 2

[0031] A production method for hot-processing billets of super duplex stainless steel ingots, using a bell-type electric soaking furnace to heat the steel ingots (ingot weight 1.5 tons) + preliminary rolling mill (850 rolling mill) for hot-processing billets, and producing 2507 cubic meters Billet (180×180×6000mm).

[0032] During the first fire rolling of the blooming mill, the soaking furnace heats the steel ingot: (A) the furnace temperature of the steel ingot is ≤400°C, and the temperature is kept for 2.5 hours; (B) the temperature is raised to 760°C at a speed of 60°C / h for 5 hours, and then Raise the temperature to 850°C and hold it for 2 hours; (C) raise the temperature to 1150°C at a rate of 80°C / h, turn over the steel ingot after holding it for 2.5 hours, and keep it for another 1.5 hours; (D) heat it up to 1180°C at a rate of 100°C / h ℃, heat preservation ≥ 60 minutes, enter the blooming mill for the first fire rolling.

[0033] Hot processing blanking of the bloomin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com