Preparation method of organic nickel oxide resistance storage film and electrical property test method thereof

A technology for preparing resistive memory and thin films, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, instruments, etc., can solve the problems of complex process and expensive equipment, and achieve the effect of simple process, convenient operation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The test method for the electrical properties of the organic nickel oxide resistance memory film prepared by the above preparation method, the specific steps are as follows:

[0033] Step 1. Connect the organic nickel oxide resistive memory film with four lead wires. The lead wires are incoming wires with a purity of 99.9%. Use metal indium to connect the lead wires to the test point using the indium pressing method, and two of the lead wires are connected to the top electrode platinum. The layer is separated and independent, and the other two leads are connected to the bottom electrode, which is separated and independent;

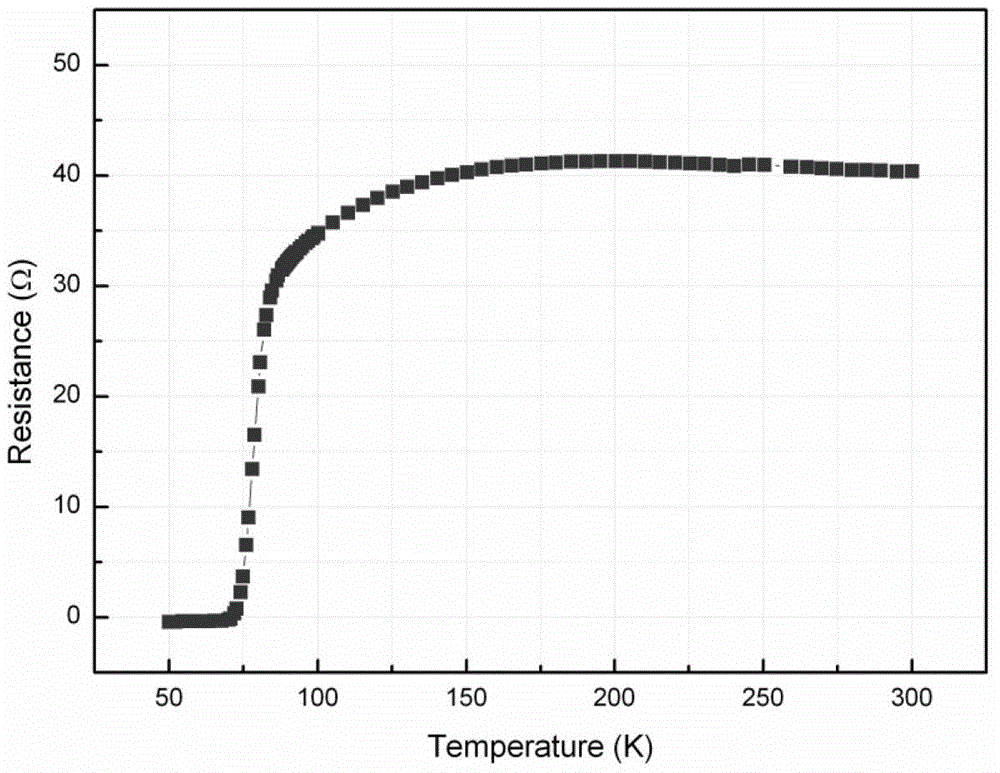

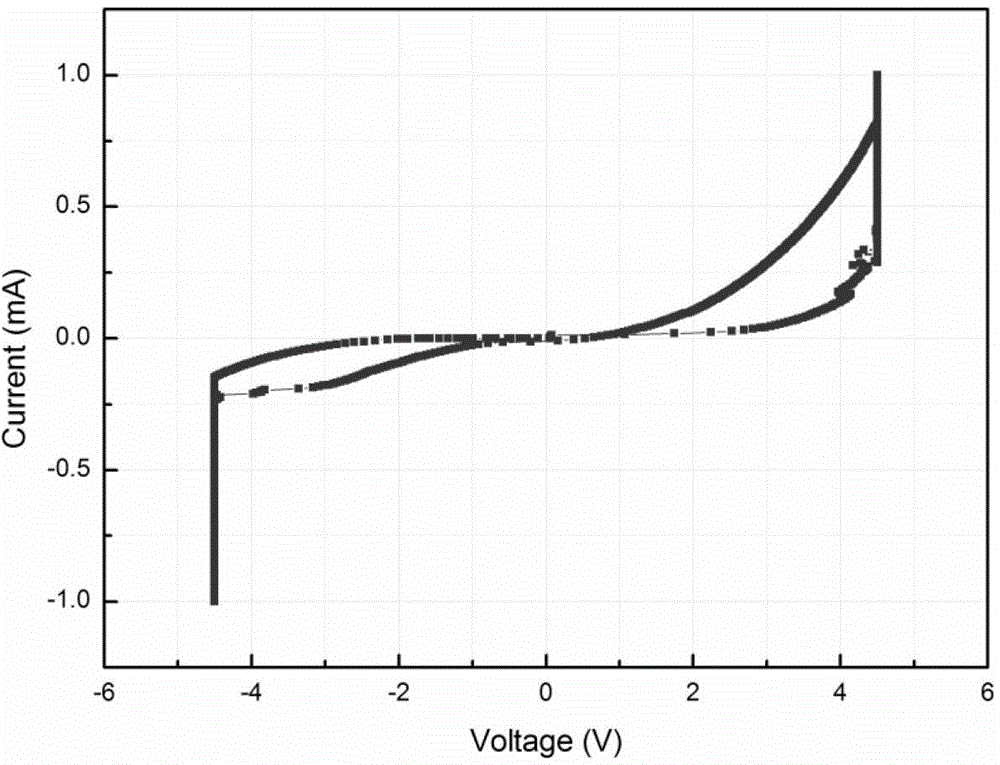

[0034] Step 2, fix the organic nickel oxide resistance memory film connected with four leads on the sample stage and put it into the material comprehensive physical property measuring instrument to measure its resistance change characteristics and fatigue characteristics. The material comprehensive physical property measuring instrument is set to ele...

Embodiment 1

[0038] Step 1, first mix nickel acetate, acetylacetone and ethylene glycol methyl ether at a molar ratio of 1:1:26 and stir for 6 hours. After fully dissolving, add nickel acetate, acetylacetone and acrylic acid at a molar ratio of 1:1:1 Acrylic acid, after stirring for 2 hours, aging for 24 hours, the organic nickel oxide sol was obtained;

[0039] Step 2, using the dipping and pulling method, using a pulling machine to pull the organic nickel oxide sol obtained in step 1 on the superconducting electrode substrate, and then drying it at room temperature to obtain an organic nickel oxide film;

[0040] Step 3, put the organic nickel oxide film obtained in step 2 into a vacuum degree of 1×10 -3 In the sputtering apparatus of Pa, the mask plate is fixed, the sputtering target material is platinum with a purity of 99.9%, and the top electrode is sputtered for 10 minutes to obtain an organic nickel oxide resistance memory film.

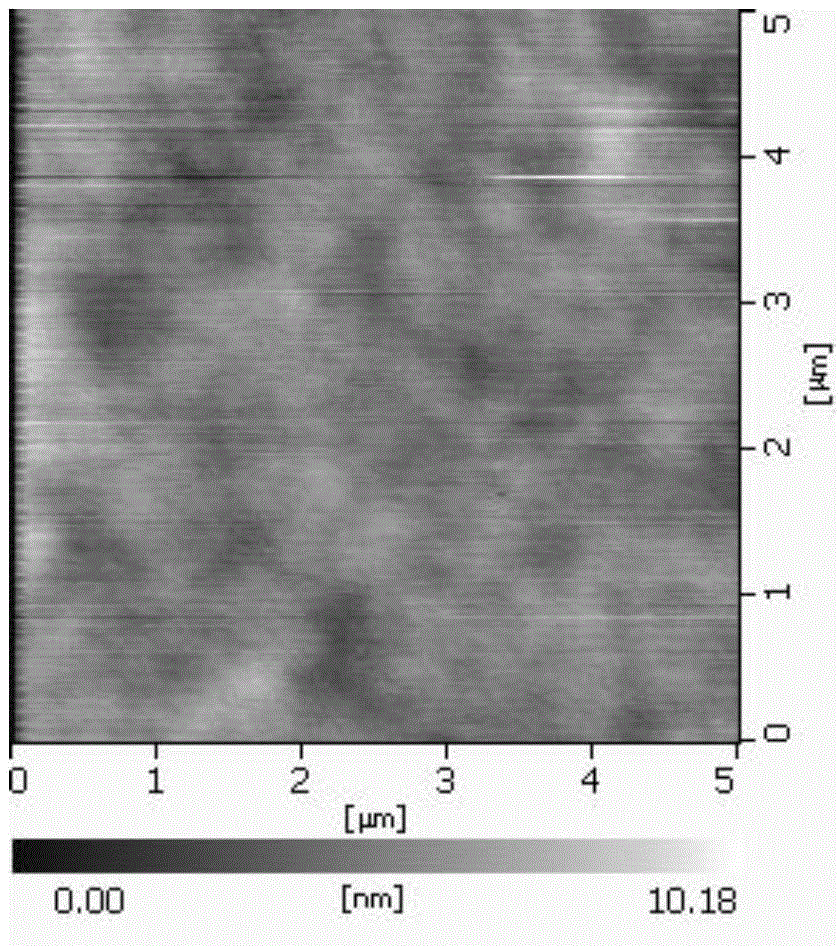

[0041] The organic nickel oxide film obtained in s...

Embodiment 2

[0047] Step 1, first mix nickel acetate, acetylacetone and ethylene glycol methyl ether at a molar ratio of 1:1:28 and stir for 5 hours. After fully dissolving, add nickel acetate, acetylacetone and acrylic acid at a molar ratio of 1:1:1 Acrylic acid, after stirring for 1.5h, aging for 22h, the organic nickel oxide sol was obtained;

[0048] Step 2, using the dipping and pulling method, using a pulling machine to pull the organic nickel oxide sol obtained in step 1 on the superconducting electrode substrate, and then drying it at room temperature to obtain an organic nickel oxide film;

[0049] Step 3, put the organic nickel oxide film obtained in step 2 into a vacuum degree of 1×10 -3 In the sputtering apparatus of Pa, the mask plate is fixed, the sputtering target material is platinum with a purity of 99.9%, and the top electrode is sputtered for 15 minutes to obtain an organic nickel oxide resistance memory film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com