Method for modifying and tackifying low-rank coals

A low-rank coal and modified technology, applied in the petroleum industry, coke ovens, etc., can solve the problems of high cost, increase the use of coking coal blending, and complicated procedures, reduce emissions, solve uneven distribution, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

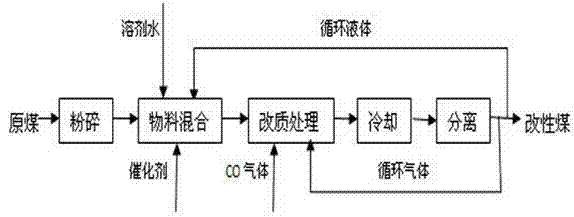

Image

Examples

Embodiment 1

[0043] Coal modification test was carried out with Xinjiang Heishan long-flame coal as raw material.

[0044] Use a sieve with a mesh number of 200 to screen the Heishan long-flame coal, weigh 30g and place it in a high-pressure reactor, then add 15g of coking wastewater, weigh 3gFe, 0.25g Co, 1.65g S and 0.1gAl, mix and add, Stir, seal, blow with CO gas and set the initial pressure to 4MPa, heat at a rate of 10°C / min until the reaction temperature is 380°C, the reaction time is 30min, and the pressure in the kettle reaches 26MPa. After the reaction is finished, the reaction kettle is naturally cooled to room temperature, the reaction materials are taken out, and the water and coal materials are separated into solid and liquid, and the separated solid is modified coal.

[0045] The modified coal was tested according to GB / T 5447-1997 with a caking index tester, and the caking index of the product was 80.

Embodiment 2

[0047] Coal Modification Test Using Shanxi Changzhi Lean Coal as Raw Material

[0048] Use a sieve with a mesh number of 120 to screen Changzhi lean coal, weigh 30g and place it in a high-pressure reactor, then add 30g of coking wastewater, weigh 2.7gFe, 0.22g Co, 1.47g S and 0.09gAl, mix and add, Stir, seal, pass in CO gas to purge and set the initial pressure to 3MPa, heat up to the reaction temperature of 360°C at a rate of 10°C / min, react for 50min, and the pressure in the kettle reaches 20 MPa. After the reaction is finished, the reaction kettle is cooled to room temperature, the reaction materials are taken out, and the water and coal materials are separated into solid and liquid, and the separated solid is modified coal.

[0049] The modified coal was tested according to GB / T 5447-1997 with a caking index tester, and the caking index of the product was 64.

Embodiment 3

[0051] Coal modification test was carried out with Shanxi Changzhi lean coal as raw material.

[0052] Use a sieve with a mesh number of 100 to screen Changzhi lean coal, weigh 30g and place it in an autoclave, then add 30g of coking wastewater, weigh 1.8gFe, 0.15g Co, 0.99g S and 0.06gAl, mix them and add them. Stir, seal, pass in CO gas to purge and set the initial pressure to 4MPa, heat up to the reaction temperature of 410°C at a rate of 10°C / min, react for 25min, and the pressure in the kettle reaches 22MPa. After the reaction is finished, the reaction kettle is cooled to room temperature, the reaction materials are taken out, and the water and coal materials are separated into solid and liquid, and the separated solid is modified coal.

[0053] The modified coal was tested according to GB / T 5447-1997 with a caking index tester, and the caking index of the product was 88.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com