Device and method for continuous recovery treatment of chlorosilane residual liquid

A chlorosilane residual liquid, recovery and treatment technology, applied in the direction of halogenated silanes, halogenated silicon compounds, etc., can solve the problems of waste, difficult operation and many impurities, and achieve the effect of increasing yield and maximizing resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

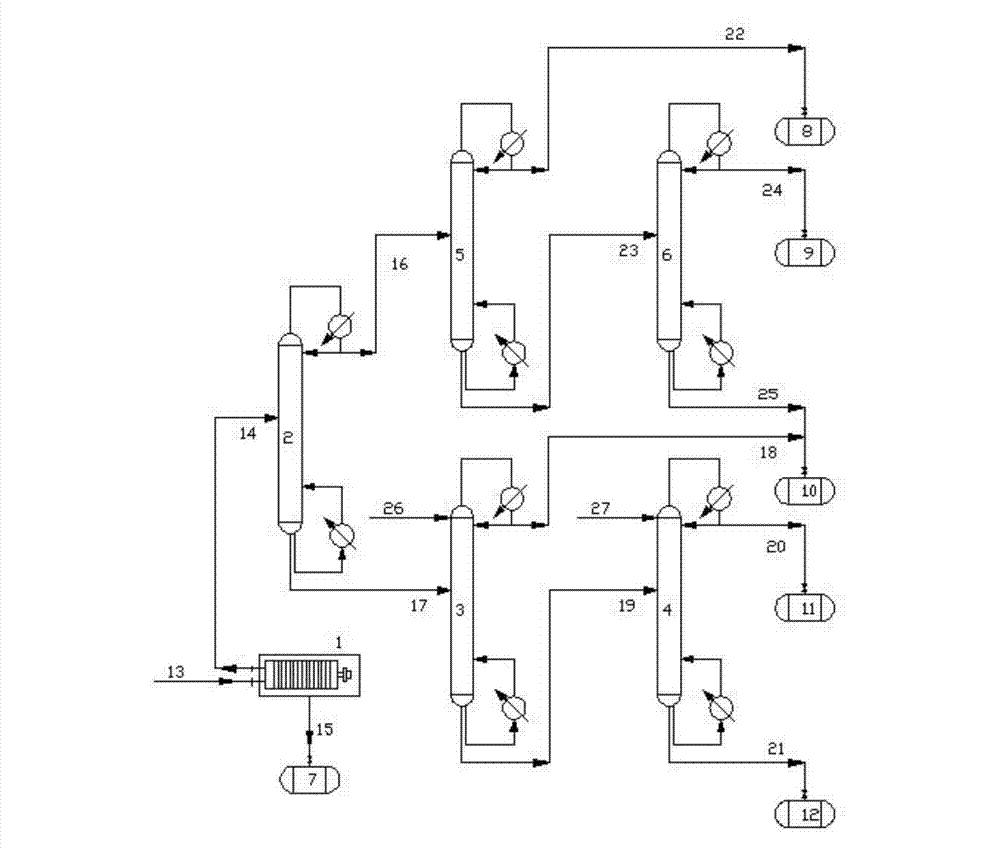

[0034] Combine below figure 1 Further details on the continuous scheme

[0035]A continuous chlorosilane residue recovery treatment device: including a filter (1), an initial distillation tower (2), a hexachlorodisilane light removal tower (3), a hexachlorodisilane weight removal tower (4), a tetrachloride Silicon dehydrogenation tower (5), silicon tetrachloride weight removal tower (6), filter residue storage tank (7), trichlorosilane storage tank (8), silicon tetrachloride storage tank (9), organochlorosilane storage tank (10), hexachlorodisilane storage tank (11), and high-boiling silicone oil storage tank (8); it is characterized in that a chlorosilane raffinate (13) feed inlet is provided on the filter (1), and a The filtrate outlet pipeline (14) is connected to the primary distillation tower (2), and the bottom is provided with a filter residue unloading pipeline (15) connected to the filter residue storage tank (7); the bottom of the primary distillation tower (2) is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com