Rolling mill roll series device and rolling mill used for rolling mill roll series device

A rolling mill and roll system technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of large roughness, increased energy consumption, manpower input, enhanced light diffuse reflection, etc., and reduces the possibility of reaching new defects , Improve the effect of chromatic aberration defects and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The core of the present invention is to provide a rolling mill roll system device, which can reduce or eliminate the color difference defects of rolled products without increasing the roughness of the rolls or increasing the number of rolling passes, thereby reducing the production of rolled products Reduce the cost, shorten the lead time of rolled products, and increase the yield of rolled products. Another core of the present invention is to provide a rolling mill with the above rolling mill roll train device.

[0018] In order to enable those skilled in the art to better understand the technical solutions provided by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

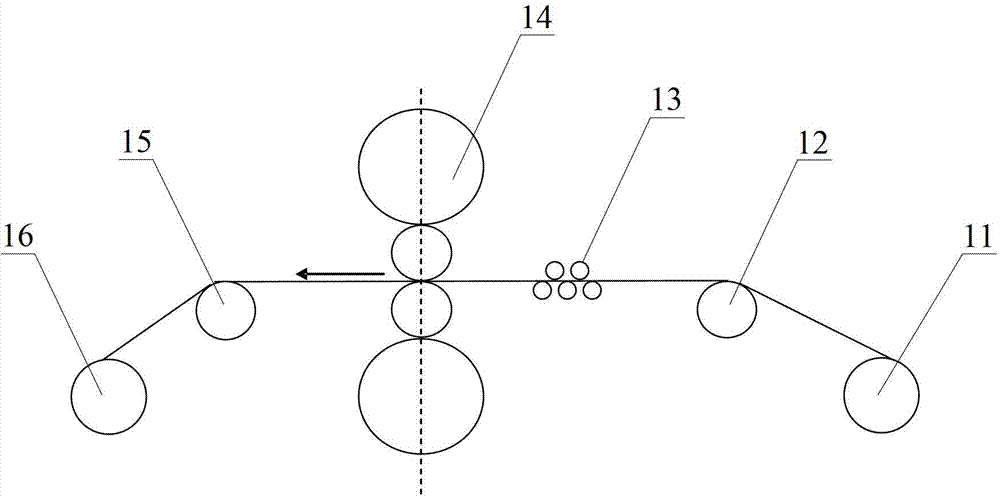

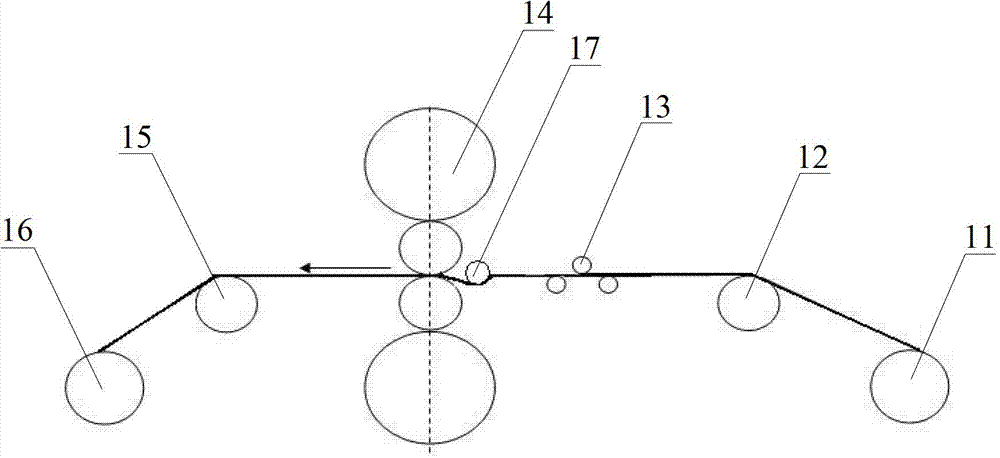

[0019] Such as figure 1 As shown, the rolling mill roll system device provided by the embodiment of the present invention includes an entrance reel 11, an entrance guide roll 12, a tension roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com