Preparation method of aerogel material capable of efficiently absorbing iodide ions and iodide steam

A technology of iodine ion and iodine vapor, which is applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of difficult collection of iodine ions and iodine molecule adsorption materials, and achieve good adsorption effect, cost, environmental protection and green , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Specific embodiment 1: The first embodiment of this embodiment is to take an aqueous dispersion of nanofibrillated natural polymer with a mass percentage content of 0.01% to 1.5%;

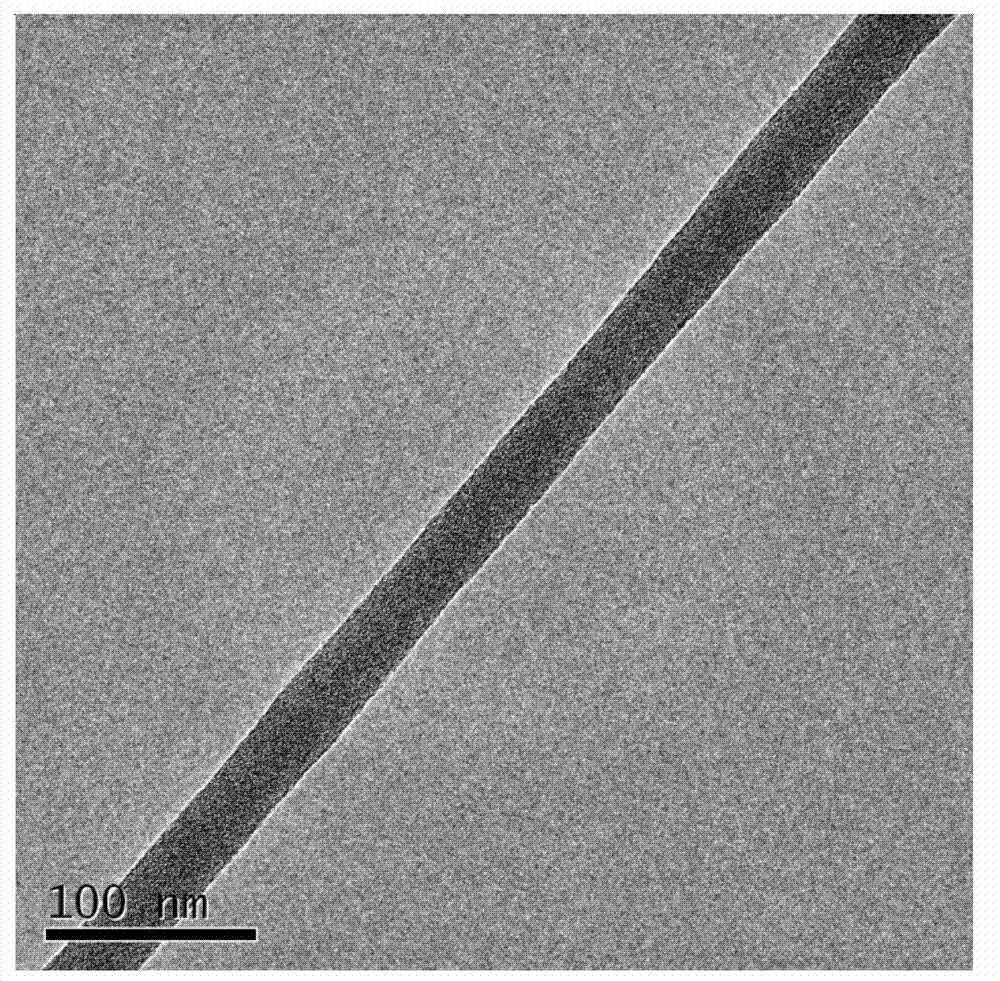

[0030] 2. Pour the aqueous dispersion of nanofibrillated natural polymer obtained in step 1 into a container and freeze-dry to obtain an ultra-light porous material composed of nanofibrils;

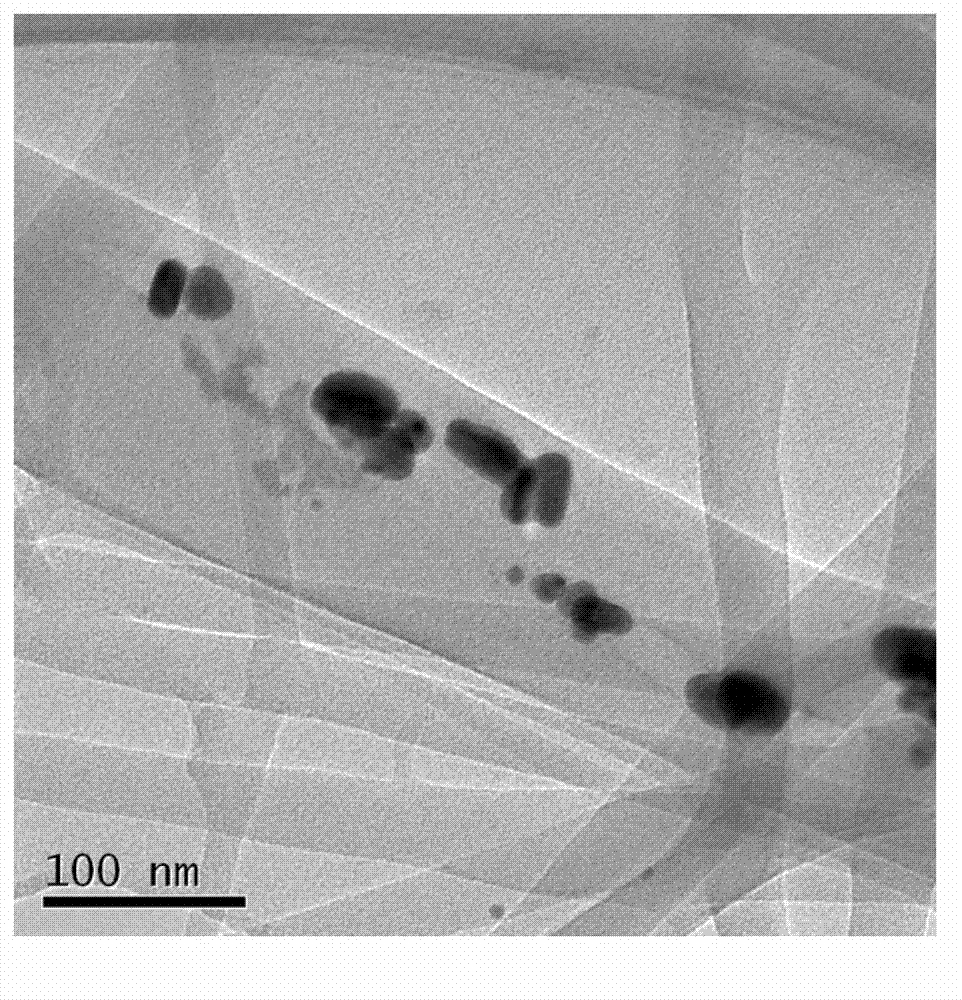

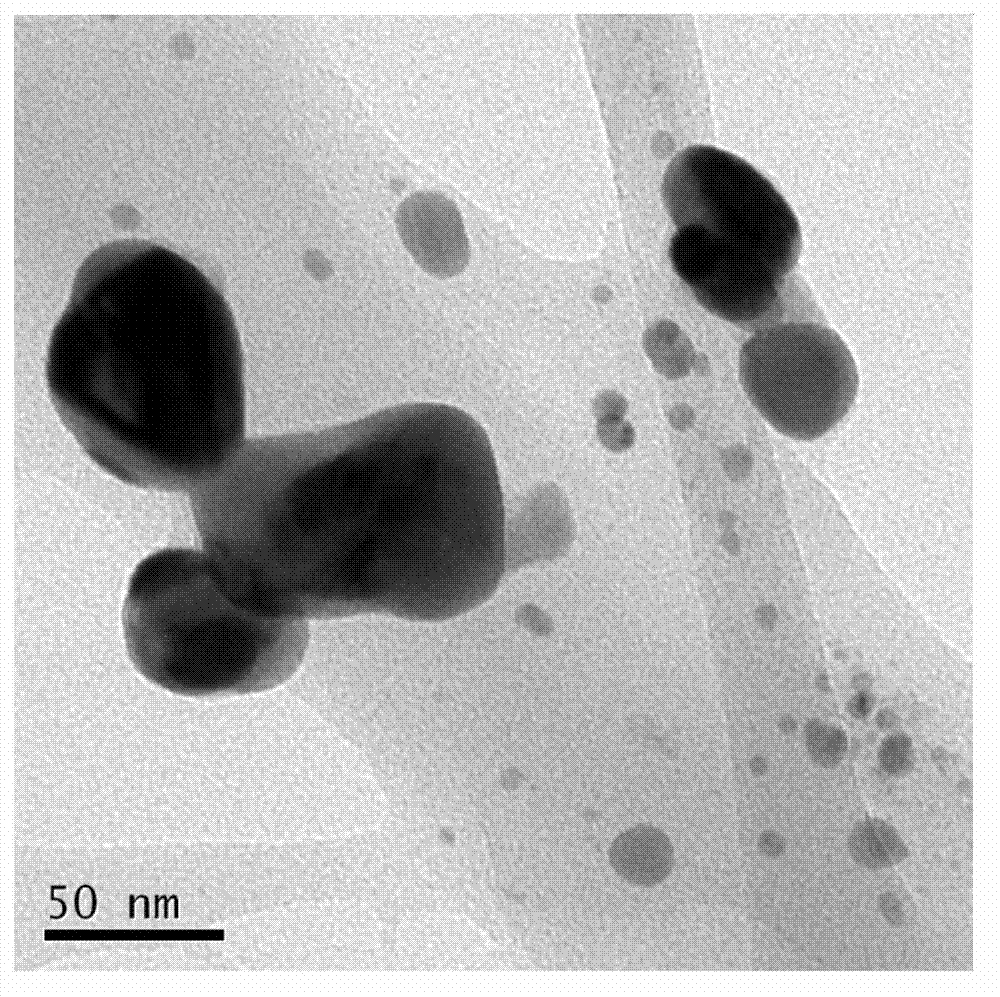

[0031] 3. Add the same volume to the ultra-light porous material obtained in step 2 at a concentration of 5×10 -5 M~5×10 -2 The silver ammonia solution of M is uniformly dispersed under ultrasound and then freeze-dried to obtain Ag-laden + Natural polymer nanofibrils of complexes;

[0032] Fourth, add Ag to the obtained in step three + The natural polymer nanofibers of the complex are added with a NaOH solution of pH=9~11, and the dispersion is uniformly dispersed under ultrasound. The dispersion is aged at room temperature and allowed to stand for 12~48h to obtain natural polymer nanofibers loaded with silver ...

specific Embodiment approach 2

[0044] Specific embodiment two: this embodiment is the same as the specific embodiment one: the ultrasonic treatment described in step two is: ultrasonic treatment is carried out under the condition of ultrasonic power of 400W-2000W for 5min-30min; high-speed shearing treatment is: Shear treatment for 5min~20min under the condition of power 600W~3000W; high pressure homogenization treatment: 5min~30min under pressure of 380~420bar; ball mill pulverization: under the condition of cylinder rotation speed of 500~600rpm The treatment is 5min-20min; the rubber milling treatment is: 5min-30min under the condition of rotating speed of 1500~3500rpm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0045] Specific embodiment three: This embodiment is the same as the specific embodiment one or two in that: the step four described in step four contains Ag + The mass ratio of the natural polymer nanofibrils of the complex to the NaOH solution is 0.05 to 1.2:1. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com