Manufacturing method of composite medical non-woven fabric absorbent pads

A non-woven and composite technology, applied in absorbent pads, applications, clothing, etc., can solve problems such as unreasonable structure, wound adhesion, etc., to reduce the contact area, avoid the skin, and shorten the treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

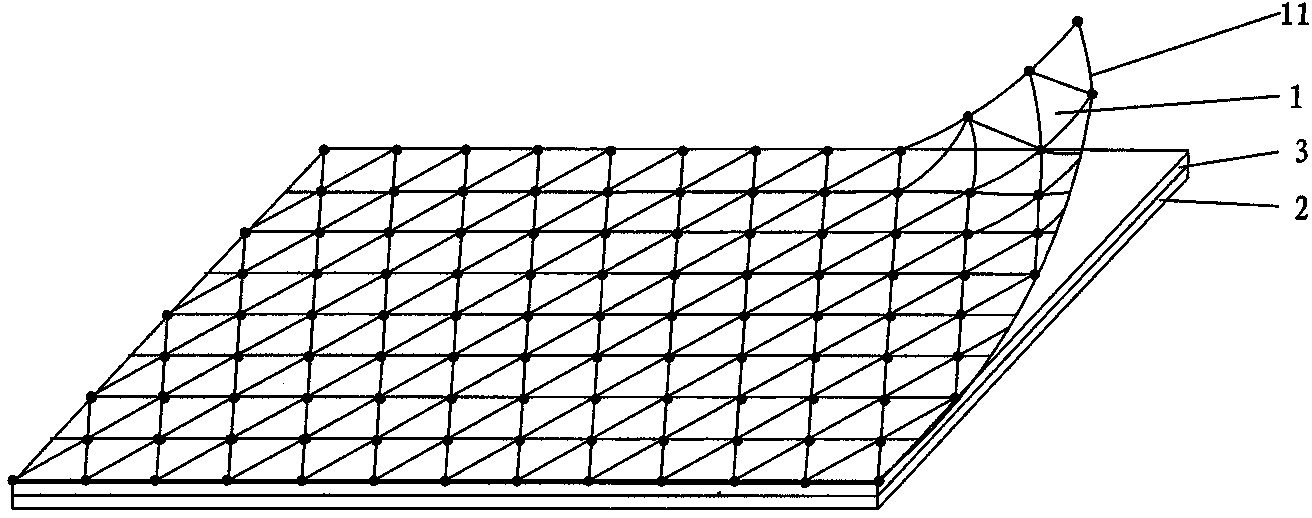

[0020] See figure 1 , provides a medical non-woven absorbent pad, which has the following structure: including an anti-adhesion layer 1 for contacting a patient's wound (also called a "wound") in use, and a waterproof pad facing outwards in use. Air-permeable layer 2 and liquid-absorbent layer 3 between anti-adhesion layer 1 and waterproof breathable layer 2, the steps of preparing the medical non-woven absorbent pad of this structure are as follows:

[0021] A) Prepare the anti-adhesion layer, put the medical non-toxic grade polyethylene (English abbreviation "PE") pellets into the screw extruder for melt extrusion, wherein: the melting temperature during melt extrusion is 125 °C, and the screw extrusion After machine melting and extrusion, the film is formed by casting film forming method, rolling out the anti-adhesion hole 11, cooling and winding to obtain the medical non-toxic grade polyethylene film as the anti-adhesion layer 1, the medical non-toxic grade polyethylene fi...

Embodiment 2

[0026] Only change the melting temperature in step A) to 110°C, change the weight of the anti-adhesion layer 1 to 20g / ㎡, and change the side length of the anti-adhesion hole 11 to 0.4mm; change the weight of the viscose fiber in step B) Change the parts by weight to 90 parts, change the parts by weight of the superabsorbent fiber to 10 parts, change the acupuncture frequency of the acupuncture machine to 650 pricks / min, and change the gram weight of the liquid-absorbent layer 3 to 300 g / ㎡; Change the melting temperature in step C) to 110°C, change the thickness of the waterproof and breathable layer 2 to 0.04mm; change the compounding temperature in step D) to 120°C. The obtained medical non-woven absorbent pad is suitable for post-operative application, and the rest are the same as those described in Example 1.

Embodiment 3

[0028] Only change the melting temperature in step A) to 120°C, change the gram weight of the anti-adhesion layer 1 to 18g / ㎡, and change the side length of the anti-adhesion hole 11 to 0.25㎜; change the viscose fiber in step B) to Change the parts by weight to 50 parts, change the parts by weight of the superabsorbent fiber to 50 parts, change the acupuncture frequency of the acupuncture machine to 800 pricks / min, and change the gram weight of the liquid-absorbent layer 3 to 200 g / ㎡; Change the melting temperature in step C) to 120°C, change the thickness of the waterproof and breathable layer 2 to 0.03mm; change the compounding temperature in step D) to 115°C. The obtained medical non-woven absorbent pad is suitable for post-operative application, and the rest are the same as those described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com