Armature plate and synchronous motor suitable for plate type coreless permanent magnet synchronous motor

A permanent magnet synchronous motor and armature disk technology, which is applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, etc. Complex process and other problems, to achieve the effect of avoiding manufacturing difficulties, light weight, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

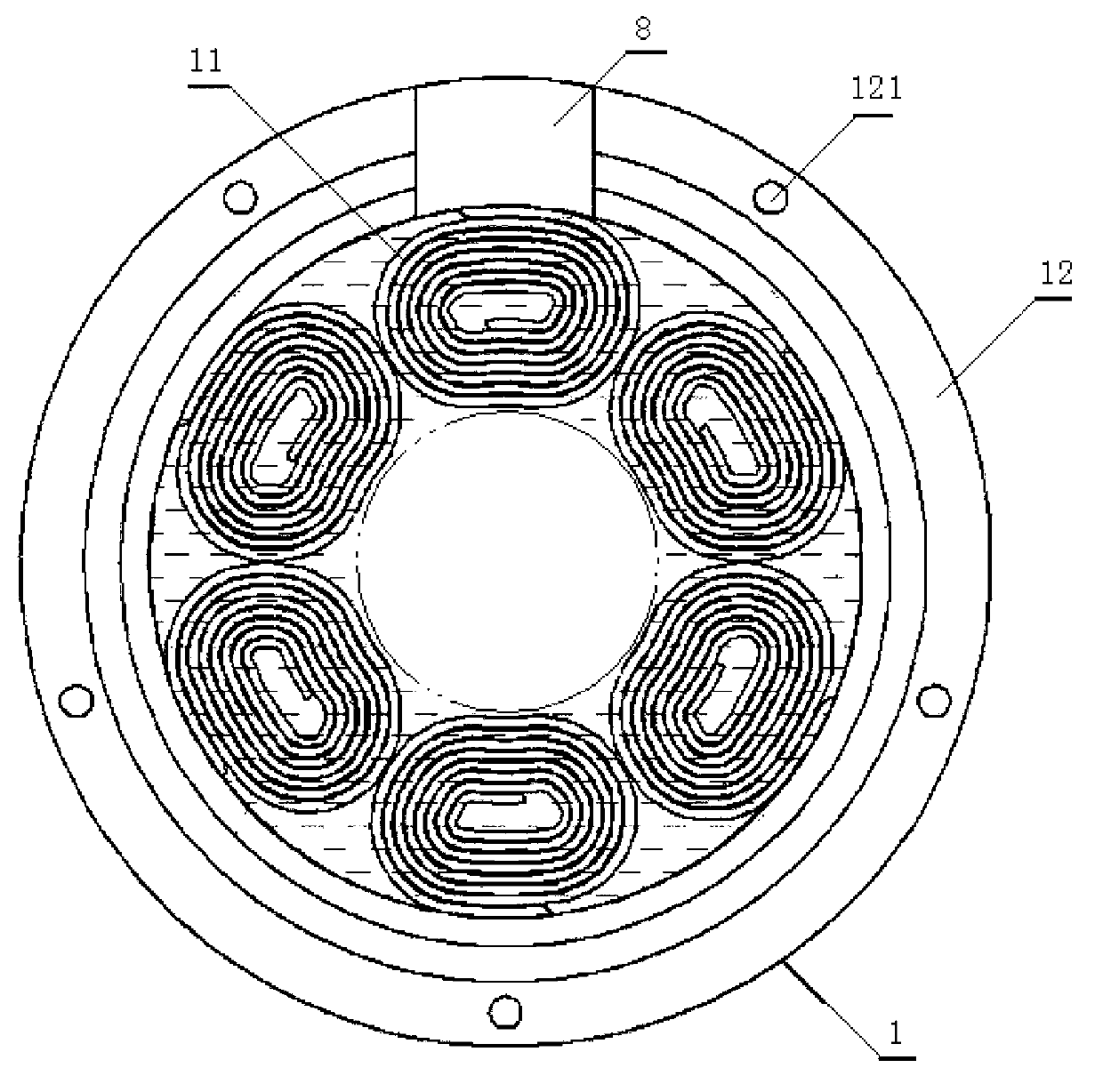

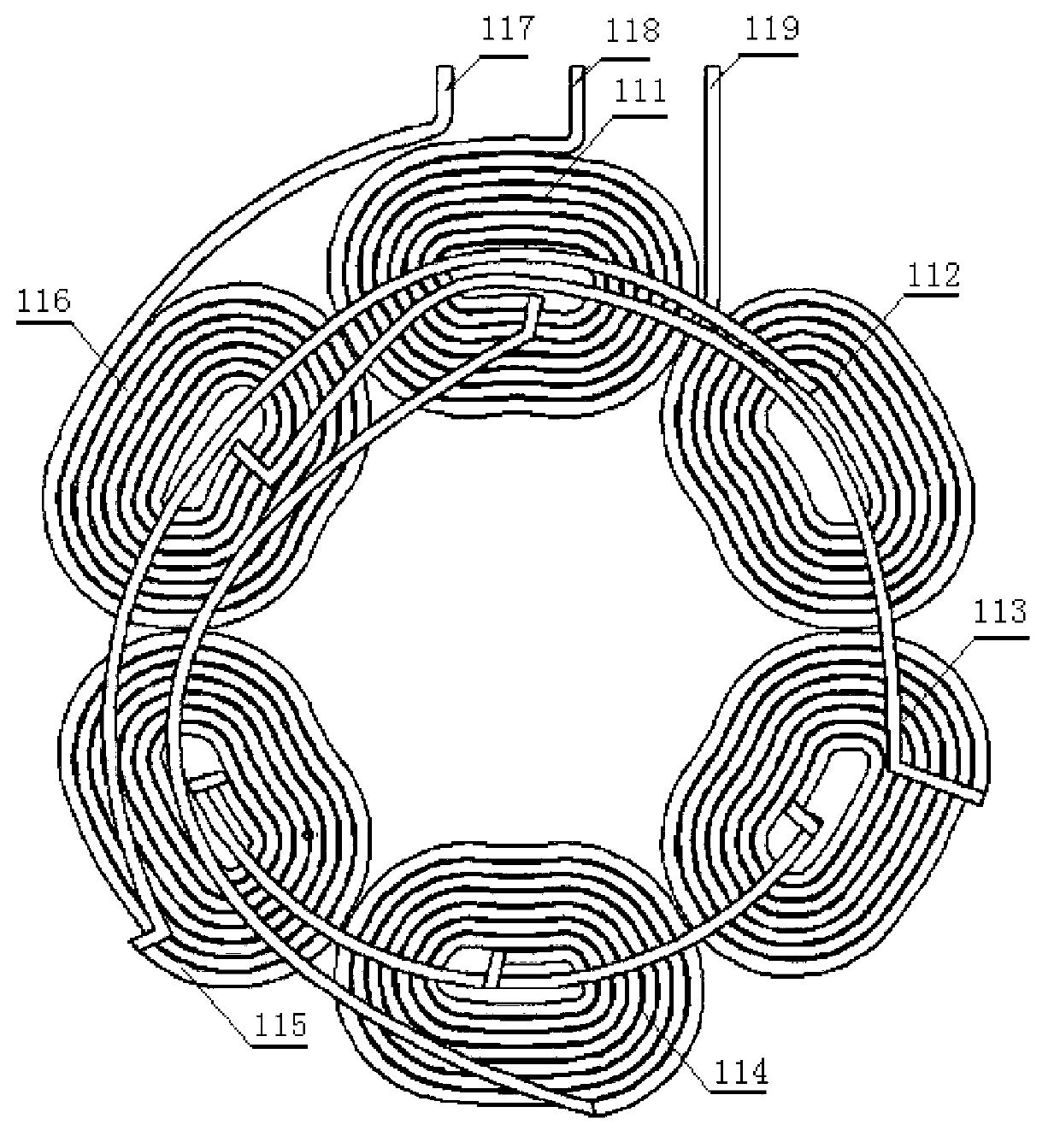

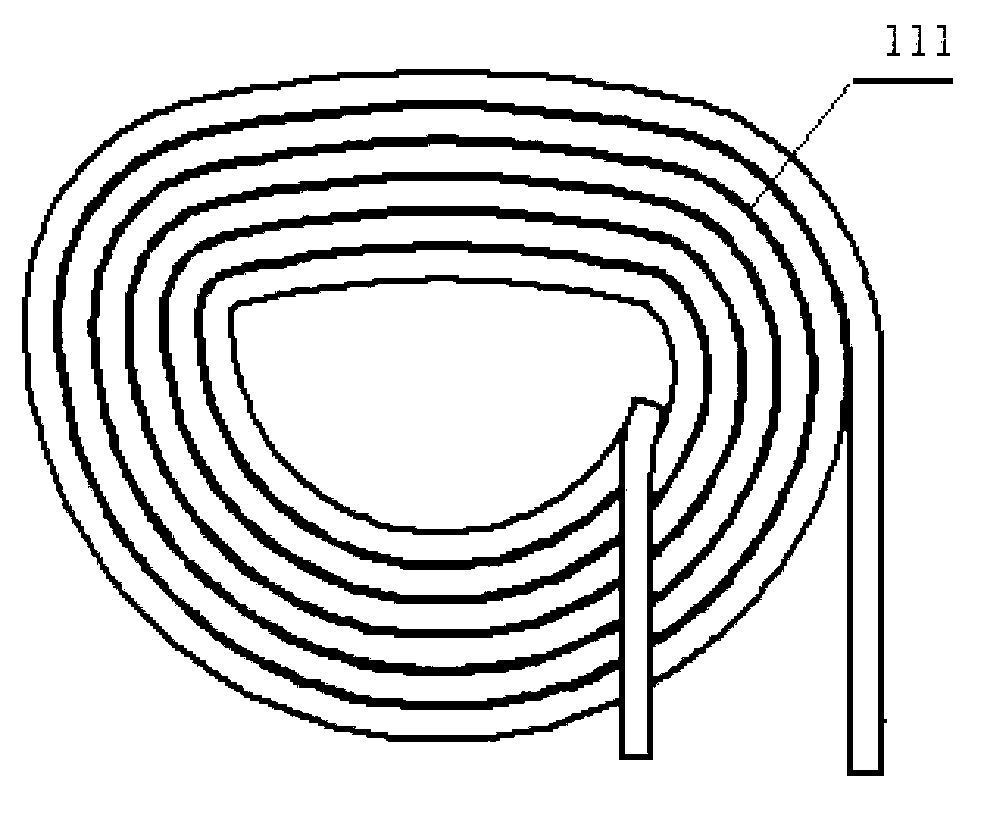

[0017] Such as figure 1 As shown, an armature disk suitable for a disk-type coreless permanent magnet synchronous motor has an armature 1, and the armature 1 has an armature disk body 12 and a coil winding 11. The armature disk body 12 is circular, and the coil The winding 11 is installed in the inner circle of the armature disk body 12. The coil winding 11 is composed of multiple winding coils. A single winding coil is wound by enamelled flat wire in a single row, and multiple winding coils are arranged in a single layer without overlapping. In a circular structure, the taps of a single winding coil are connected and drawn out according to the performance of the required synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com