Plug-in mounting type balance valve

A balance valve and plug-in technology, applied in the field of hydraulic valves, can solve problems such as easy vibration, increased processing costs, and fewer damping links of the balance valve, and achieve the effects of easy size assurance, simple manufacturing process, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

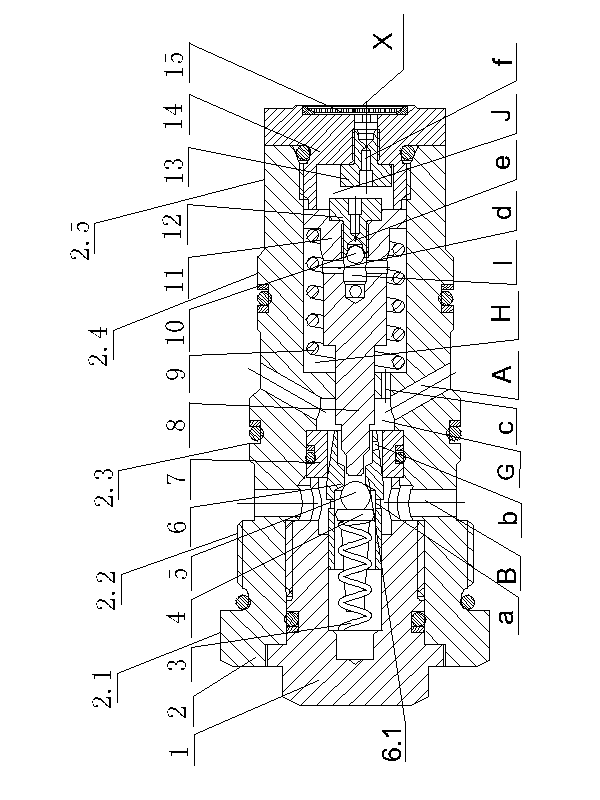

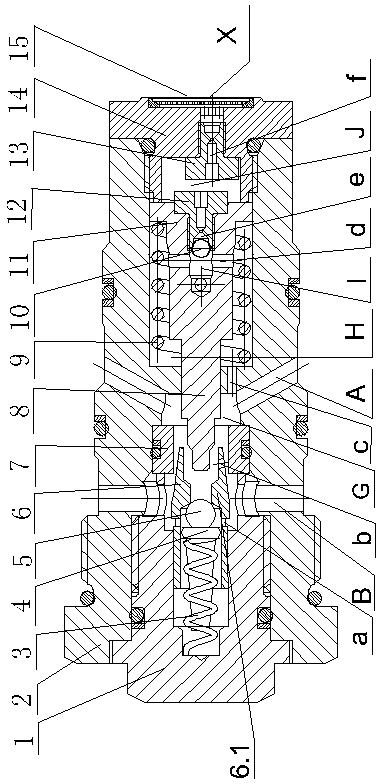

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, a plug-in balance valve includes a cylindrical valve body 2 with a first oil port A and a second oil port B and a first chamber G and a second chamber H arranged in the axial direction, respectively The end cover 1, the screw plug 14, the valve core 6, the steel ball, the valve seat 7 and the piston 11 covered with the second spring are sealingly connected at both ends of the valve body 2; the rear end of the screw plug 14 is provided with a third oil port X, the third oil port X is provided with a filter 15 and a second damper 13, the valve seat 7 is set in the first chamber G of the valve body 2, and is located at the first oil port A, the second between the oil ports B; the front section of the valve core 6 is slidingly fitted in the end cover 1, the rear section of the valve core 6 is fitted in the through hole of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com