Preparation method of Al-Mn alloy prevention plating layer on surface of metallic matrix

An al-mn and alloy technology, which is applied in the field of preparation of ionic liquid electrodeposited Al-Mn alloy protective coating on the surface of metal substrates, can solve the problems of high cost, high energy consumption, corrosion of containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] Preparation of Al-Mn Alloy Protective Coating

[0075] The invention provides a method for preparing an Al-Mn alloy protective coating by an electroplating process, the method comprising:

[0076] The electroplating solution prepared by the above method is used as a plating solution, a metal substrate is used as a cathode, and a high-purity aluminum is used as an anode to form an electroplating system, and an Al-Mn alloy protective coating is obtained by electrodeposition.

[0077] The metal matrix is not particularly limited, and is generally an active metal or alloy that is difficult to plate, preferably selected from the following group: NdFeB permanent magnet, magnesium alloy, lithium alloy, and aluminum alloy.

[0078] Preferably, the plating solution is heated and stirred before electroplating.

[0079] Before electroplating, a certain pretreatment can be optionally performed on the metal substrate to improve the bonding force between the plating layer and the substrate. ...

Embodiment 1

[0095] Example 1: Preparation of Al-Mn alloy protective coating on the surface of NdFeB magnet

[0096] In Example 1, the metal matrix is a sintered NdFeB magnet, and the ionic liquid is aluminum chloride (AlCl 3 )-BMIC (1-butyl-3-methylimidazole chloride), add anhydrous manganese chloride (MnCl 2 ), stir to dissolve, and electrodeposit on the surface of the NdFeB magnet to obtain an Al-Mn alloy protective coating.

[0097] The specific preparation method of the Al-Mn alloy protective coating obtained by electrodeposition of the ionic liquid on the surface of the NdFeB magnet includes the following steps.

[0098] (1) Preparation of ionic liquid

[0099] Ready to configure aluminum chloride (AlCl 3 )-BMIC (1-butyl-3-methylimidazole chloride) instruments: jars, beakers, keys, electronic scales, glass rods and magnets. All equipment must be completely dried and placed in the glove box. Weigh BMIC (1-butyl-3-methylimidazole chloride) in a jar in the glove box, and then weigh aluminum ...

Embodiment 2

[0109] Example 2: Electroplating effect under different electroplating solution concentration conditions

[0110] In Example 2, the metal matrix is a sintered NdFeB magnet, and the ionic liquid is aluminum chloride (AlCl 3 )-BMIC (chlorinated 1-butyl-3-methylimidazole), which is basically the same as the steps in Example 1. In step (3) electrodeposition of Al-Mn alloy coating, weigh 1.573g of anhydrous chlorinated Manganese (MnCl 2 ) Add to 50ml ionic liquid and stir to dissolve to form a 0.25mol / L plating solution.

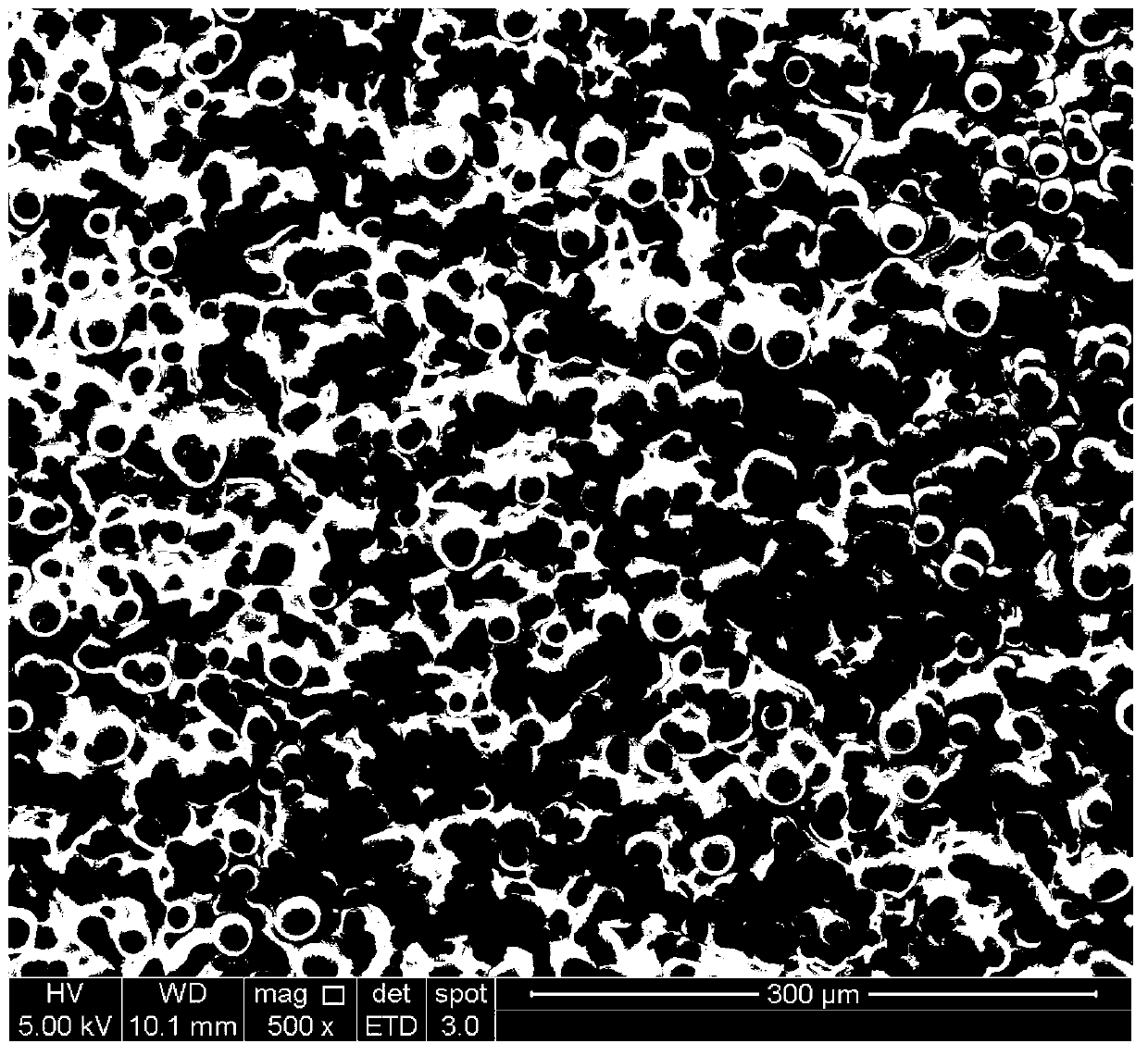

[0111] The surface morphology of the Al-Mn alloy coating obtained by electrodeposition is as attached image 3 As shown, the surface is uniform and dense, which is brighter than the surface of the plating layer in Example 1. However, because the surface morphology was observed under high magnification, microscopic cracks were generated, resulting in its corrosion resistance inferior to the alloy coating prepared in Example 1.

[0112] The corrosion resistance test re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com