Low-gloss clear finishing coat and preparation method thereof

A clear finish and matte technology, applied in coatings, polyester coatings, etc., can solve the problems of low hardness, affect the appearance, easy to be scratched, etc., achieve good hand feel, strong scratch resistance, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

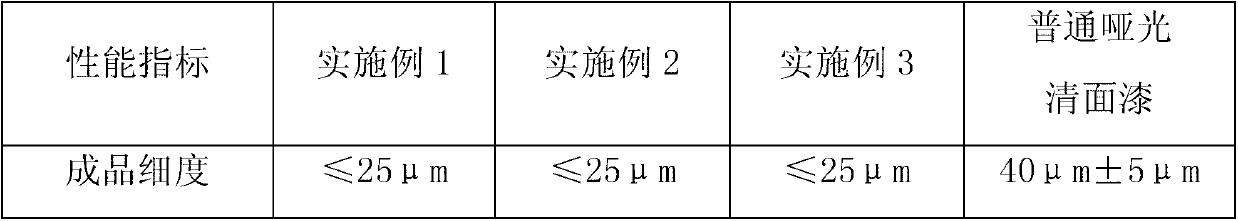

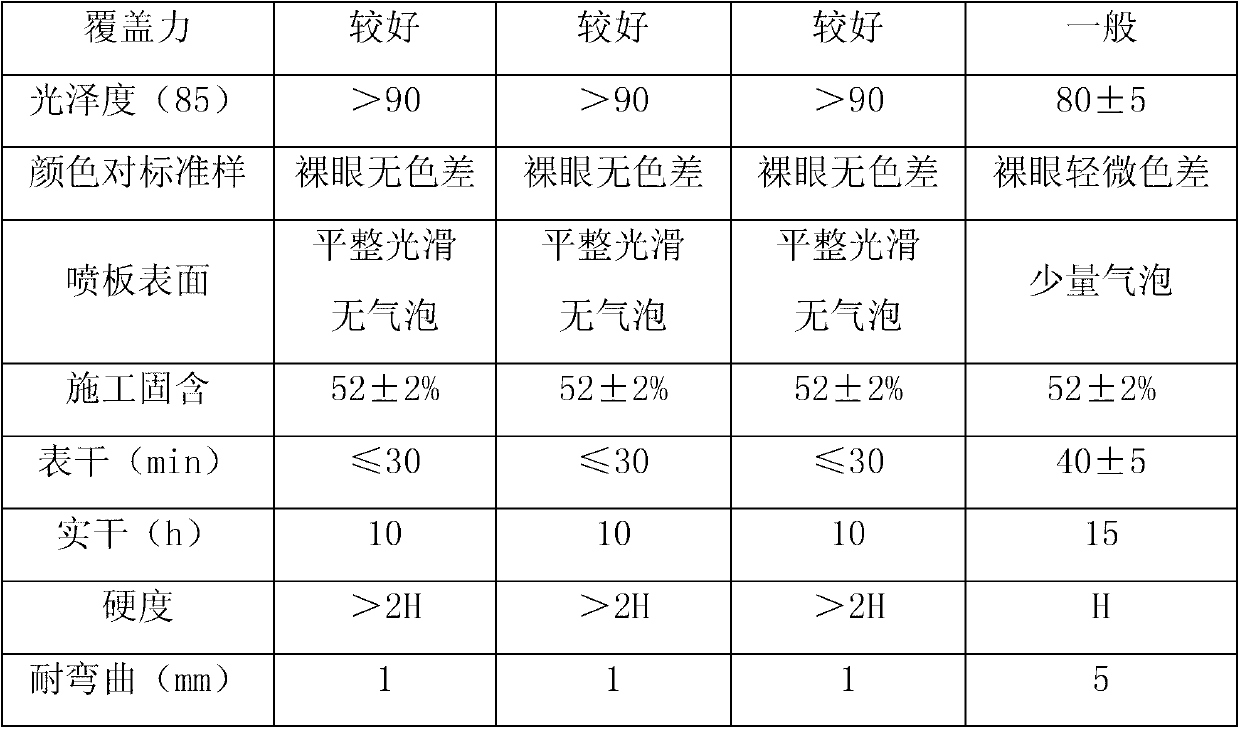

Examples

example 1

[0018] A kind of matte clear finish paint, is made up of following components: modified alkyd resin 71.5kg, xylene 5.3kg, butyl acetate 4.6kg, dispersant 0.25kg, defoamer 0.10kg, bentonite 4.2kg, matting powder 4.8kg, 1 / 4 nitrocellulose liquid 4.2kg, cyclohexanone 1.8kg, leveling agent 0.40kg, ethylene glycol ethyl ether acetate 1.8kg, drier 0.25kg; In the present embodiment, described leveling agent is made of 0.10 kg of organo-modified siloxane and 0.30 kg of polyether-modified polydimethylsiloxane are mixed, and the drier is dibutyltin dilaurate;

[0019] Described modified alkyd resin is made up of 20kg vegetable oleic acid, 18kg glycerol, 5kg pentaerythritol, 15kg terephthalic acid, 0.1kg hypophosphorous acid, 4kg phthalic anhydride, 5kg benzoic acid, 4.5kg xylene, 20kg acetone and 0.15kg dispersant; Its preparation method is: put vegetable oleic acid, glycerin, pentaerythritol, terephthalic acid and hypophosphorous acid into the reaction kettle, pass inert gas into the r...

example 2

[0022] A matte clear finish paint, consisting of the following components: 72.5kg modified alkyd resin, 4.8kg xylene, 4.8kg butyl acetate, 0.15kg dispersant, 0.20kg defoamer, 3.8kg bentonite, matting powder 5.1kg, 1 / 4 nitrocellulose liquid 3.6kg, cyclohexanone 2.4kg, leveling agent 0.28kg, ethylene glycol ethyl ether acetate 2.1kg, drier 0.15kg; In the present embodiment, described leveling agent is made of 0.20kg of organo-modified siloxane and 0.08kg of polyether-modified polydimethylsiloxane are mixed, and the drier is dibutyltin dilaurate;

[0023] Described modified alkyd resin is made up of 25kg vegetable oleic acid, 15kg glycerol, 6kg pentaerythritol, 10kg terephthalic acid, 0.15kg hypophosphorous acid, 3kg phthalic anhydride, 6kg benzoic acid, 3.5kg xylene, 25kg acetone and 0.1kg dispersant; Its preparation method is with embodiment 1.

[0024] The production method of described matt varnish is the same as in Example 1.

example 3

[0026] A kind of matte clear finish paint, is made up of following components: modified alkyd resin 72kg, xylene 5kg, butyl acetate 5kg, dispersant 0.2kg defoamer 0.15kg, bentonite 4.0kg, matting powder 5.0kg, 1 / 4 nitrocellulose liquid 4.0kg, cyclohexanone 2.0kg, leveling agent 0.35kg; It is prepared by mixing methyl siloxane, 2.0 kg of ethylene glycol ether acetate, and 0.2 kg of drier, which is dibutyltin dilaurate.

[0027] The modified alkyd resin is dispersed by 23kg vegetable oleic acid, 16kg glycerol, 5.5kg pentaerythritol, 12kg terephthalic acid, 0.12kg hypophosphorous acid, 3.5kg phthalic anhydride, 5.5kg benzoic acid, 4.0kg xylene, 22kg acetone and 0.12kg Agent composition; Its preparation method is with embodiment 1.

[0028] The production method of described matt varnish is the same as in Example 1.

[0029] In the above three embodiments, the dispersant adopts the EFKA-4010 dispersant produced by Guangzhou Shenggao Chemical Technology Co., Ltd.; the defoamer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com