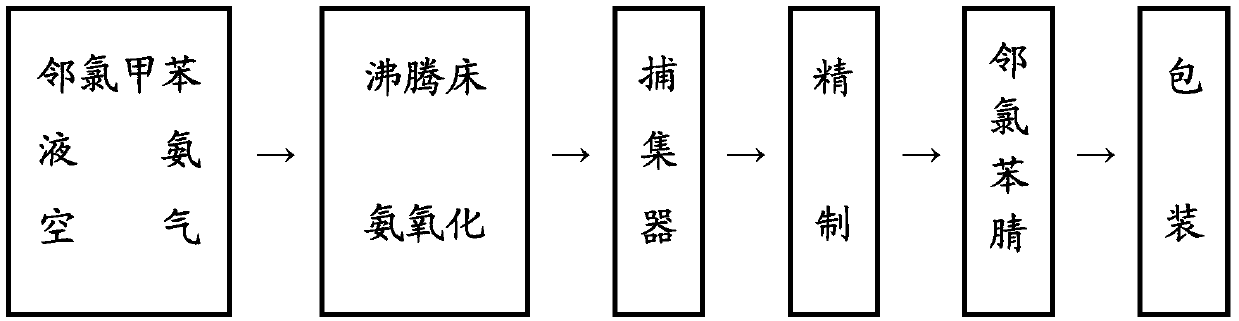

Production process for preparing chlorobenzonitrile through ammoxidation

A technology of o-chlorobenzonitrile and ammoxidation method, applied in the chemical industry, can solve the problems of little economic significance and high price of o-chlorobenzoic acid, achieve the effects of suppressing side reactions, improving production technology, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

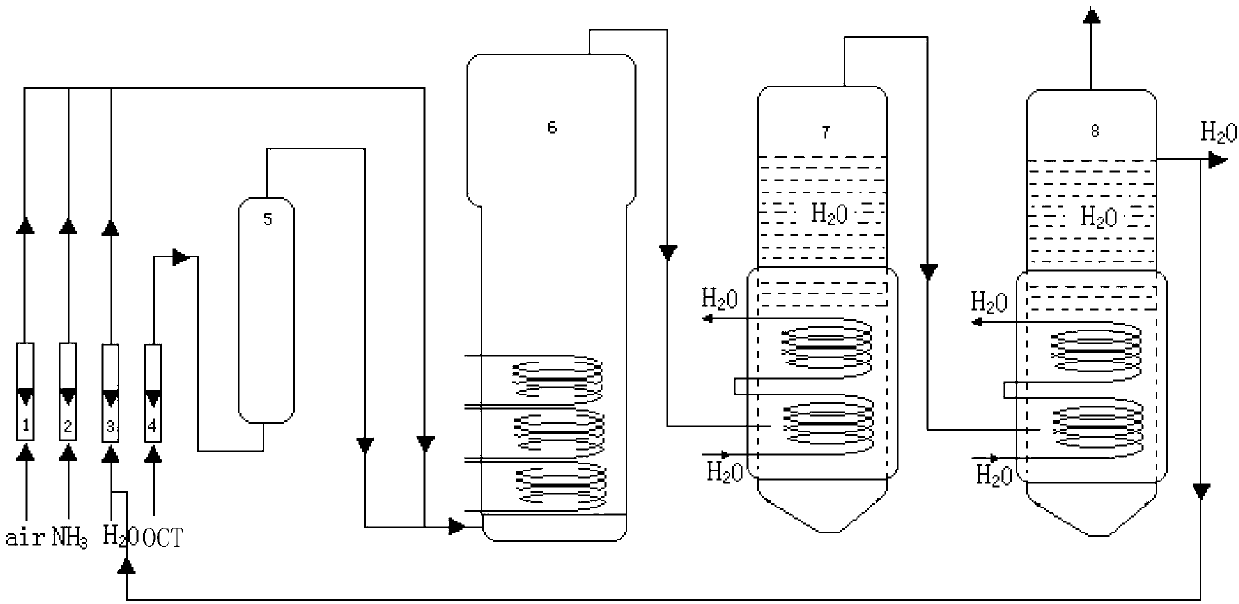

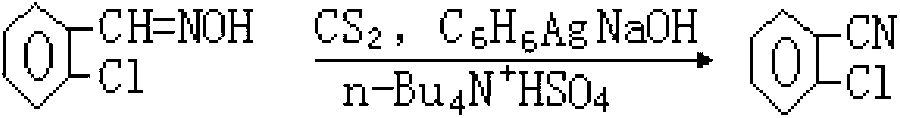

Method used

Image

Examples

Embodiment 1

[0052] First, the activated catalyst VP 0.7 Ce 0.3 Sb 0.5 o 6.1 Fill to In the ebullated bed reactor, the height of the static bed is 2m (about 1.5t of activated catalyst is required), and the heated air (450~480°C) is passed through, and the ammonia is passed through 8m after heating and boiling to 400°C. 3 / h. Continue to pass hot air (350°C) for 3 hours, rise to 500°C, keep warm and activate for 8 hours. Cool down to 370°C, feed ammonia 4m 3 / h, air 200m 3 / h, o-chlorotoluene 56kg / h, water vapor 10m 3 / h, adjust the cooling water to control the reaction temperature at 370~380°C. After the reaction is completed, the crude product with o-chlorobenzonitrile content greater than 99.5% can be collected, and the yield is as high as 94%. The catalyst has not changed after continuous operation for more than one year (no deactivation, no carbon absorption).

Embodiment 2

[0054] First, the activated catalyst VP 2 CaO 12 Fill to In the ebullated bed reactor, the height of the static bed is 2m (about 1.5t of activated catalyst is required), and the heated air (450~480°C) is passed through, and the ammonia is passed through 8m after heating and boiling to 400°C. 3 / h. Continue to pass hot air (350°C) for 3 hours, rise to 500°C, keep warm and activate for 8 hours. Cool down to 370°C, feed ammonia 4m 3 / h, air 200m 3 / h, o-chlorotoluene 56kg / h, water vapor 10m 3 / h, adjust the cooling water to control the reaction temperature at 370~380°C. After the reaction is completed, the crude product with o-chlorobenzonitrile content greater than 99.5% can be collected, and the yield is as high as 92%. The catalyst has been continuously operated for more than one year without change (no deactivation, no carbon absorption).

Embodiment 3

[0056] First, the activated catalyst VPCeSb 0.5 o 8 Fill to In the ebullated bed reactor, the height of the static bed is 2m (about 1.5t of activated catalyst is required), and the heated air (450~480°C) is passed through, and the ammonia is passed through 8m after heating and boiling to 400°C. 3 / h. Continue to pass hot air (350°C) for 3 hours, rise to 500°C, keep warm and activate for 8 hours. Cool down to 370°C, feed ammonia 4m 3 / h, air 200m 3 / h, o-chlorotoluene 56kg / h, water vapor 10m 3 / h, adjust the cooling water to control the reaction temperature at 370~380°C. After the reaction is completed, the crude product with o-chlorobenzonitrile content greater than 99.5% can be collected, and the yield is as high as 93%. The catalyst has been continuously operated for more than one year without change (no deactivation, no carbon absorption).

[0057]In the preparation process of the above-mentioned examples, the waste water from the process of ammoxidation of o-chloro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com