A kind of sedimentation superimposed biological contact oxidation combination tank and its treatment process

A biological contact, oxidation tank technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. sludge blockage and other problems, to facilitate management, improve treatment effect, and ensure the effect of effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

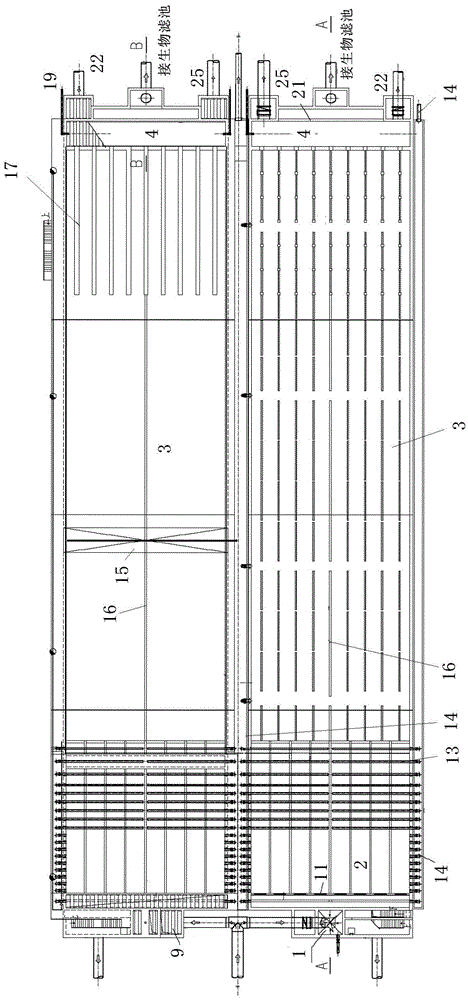

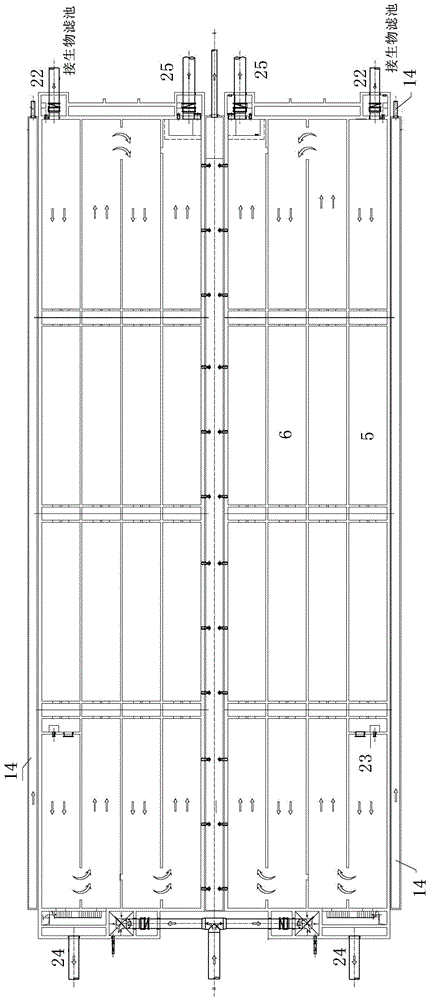

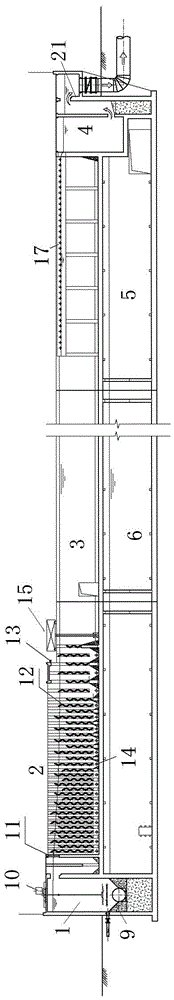

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] The present invention is a combined tank, which mainly includes a mechanical mixing tank 1, a folded plate flocculation tank 2, an advection sedimentation tank 3, a biological contact oxidation tank 4, a lower superimposed disinfection contact tank 5 and a clear water tank 6, and an independent external The blower room and the follow-up biological filter are composed. The mechanical mixing tank 1 is equipped with water inlet pipe and water inlet valve well 9, coagulant dosing and mixing equipment 10; The mud discharge pipe and mud discharge tank 14; the advection sedimentation tank 3 is equipped with a dredger 15, a diversion wall 16, and a finger-shaped groove 17; the biological contact oxidation tank 4 is equipped with a filler 18, an aerator and an aeration pipeline 19 , bottom perforated mud discharge pipeline and mud discharge tank 20, wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com