Bagging and encasement all-in-one machine

An all-in-one machine and bag-packing technology, which is applied in packaging, packaging bottles, packaging food, etc., can solve the problems of product damage, waste of manpower, and low work efficiency, and achieve the effects of convenient use, reasonable structure, and high packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

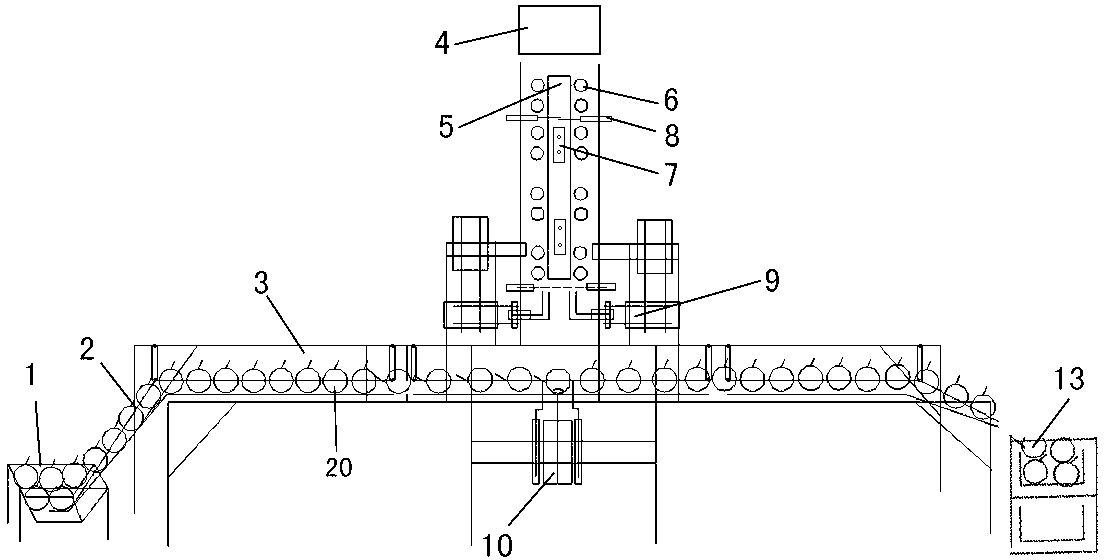

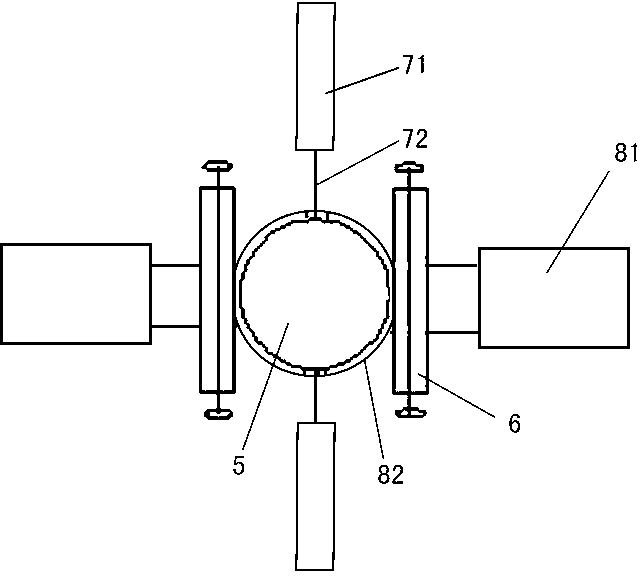

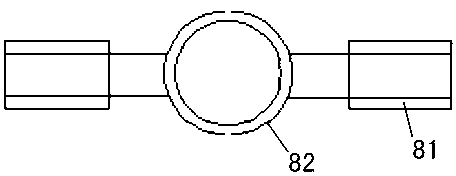

[0018] see Figure 1 to Figure 6 As shown, the present invention provides a bagging and boxing all-in-one machine, which includes a transmission system, a bagging system, a boxing system 13 and a control system. 2. The worktable conveying device 3 located at the rear of the feeding conveyor belt; the bagging system is located in the middle of the workbench conveying device, including a net sleeve feeding roller 4, a net sleeve cylinder 5 located below the net sleeve feeding roller, Conveying rollers 6 located on the left and right sides of the net sleeve cylinder, fixed brackets 7 located on the front and rear sides of the net sleeve cylinder, net sleeve cutters 8 located on the upper half of the net sleeve cylinder, and net sleeves located below the net sleeve cylinder Opening device 9, the negative pressure adsorption pushing device 10 below the workbench conveyor below the net cover opening device; the fixed support includes telescopic arm 71, support frame 72, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com