Modular integrated compressed air purification device

A technology of compressed air and purification equipment, which is applied in the direction of combined equipment, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of product scrapping, lower production efficiency, and large space occupation, and achieve convenient installation and maintenance and compact structure. Reasonable, small temporary use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

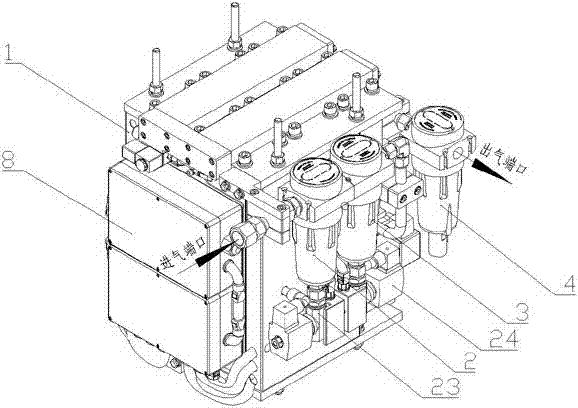

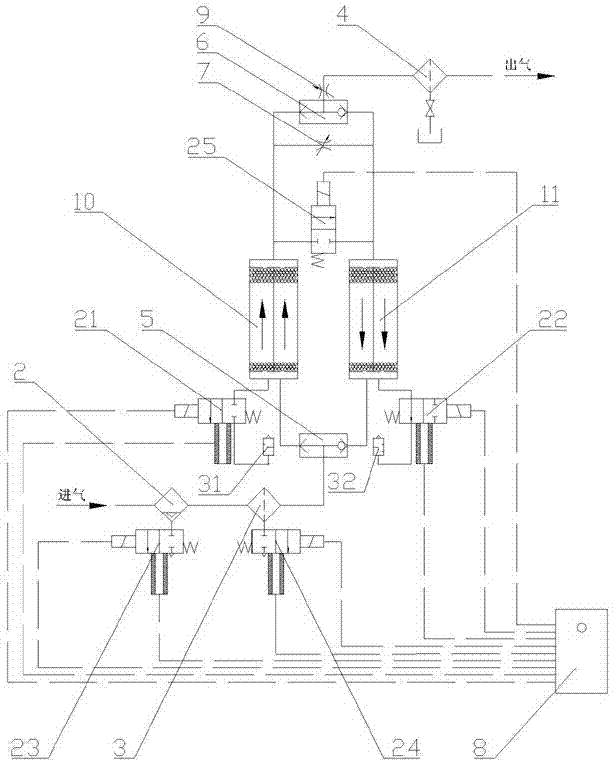

[0012] like figure 1 , figure 2 As shown, the modular integrated compressed air purification device of the present invention includes a dryer 1, an oil-water separator 2 arranged on the side wall of the dryer 1, a high-efficiency filter 3, a dust filter 4, and an electrical control device 8 And the discharge solenoid valve I21, the discharge solenoid valve II22, the discharge solenoid valve III23, the discharge solenoid valve IV24, and the rapid boost valve 25 electrically connected to the electrical control device 8, the unpurified compressed air output from the upstream air compressor passes through in sequence The oil-water separator 2, the high-efficiency filter 3, the dryer 1 and the dust filter 4 are processed and delivered to the downstream gas equipment. The dryer 1 includes a parallel double-chamber module structure, and The inlet valve assembly and the outlet valve assembly connected at both ends of the parallel double-cavity module structure, the inlet valve assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com