Preparation method of hydrogen-microbubble-containing aqueous solution, and product and application of method

An aqueous solution and hydrogen technology, applied in the field of biomedicine, can solve the problems of unstable concentration, difficult to control, short storage time, etc., and achieve the effects of improving solubility, reducing dosage and controllable concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

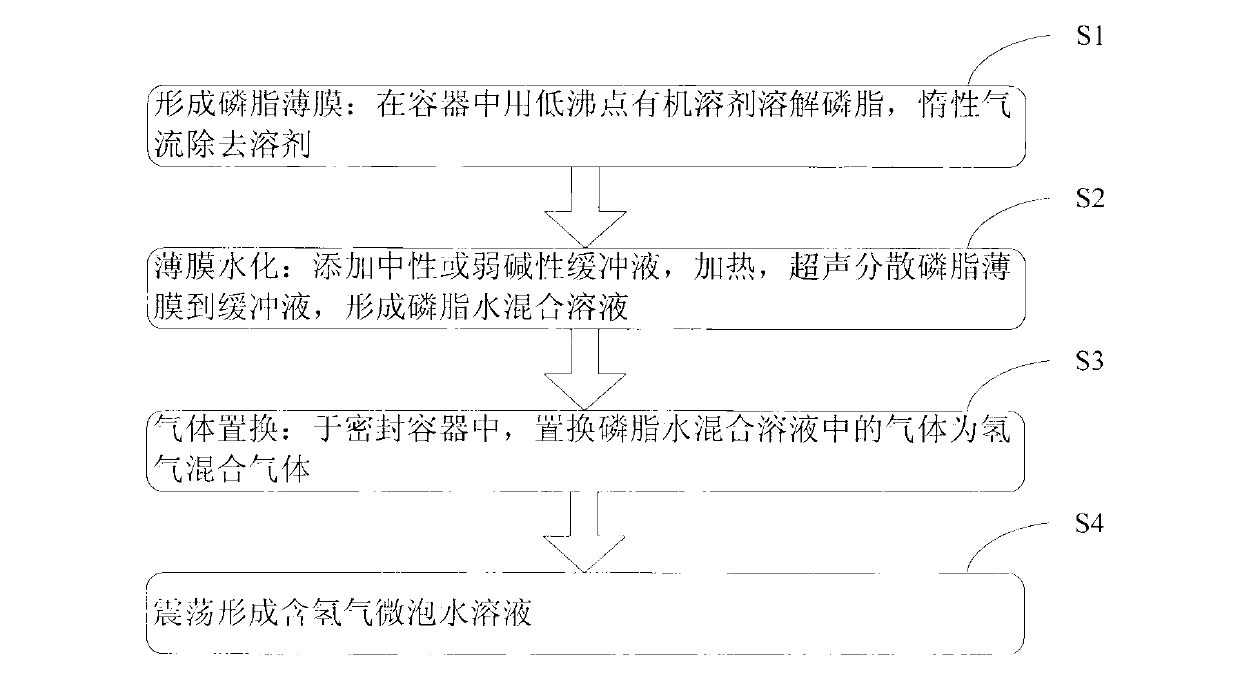

Method used

Image

Examples

Embodiment 1

[0064] Preparation of Hydrogen Microbubble Aqueous Solution

[0065] In S1, a certain amount of 1,2-arachidylglycerylphosphatidylcholine (20:0, PC) and 1,2-distearoylglycerylphosphatidylcholine modified by polyethylene glycol 2000 were added in a 90:10 molar ratio. Ethanolamine (DSPE-PEG) was mixed in chloroform with a vortex mixer. The chloroform was removed with a dry nitrogen flow to form a uniform film of the dissolved material on the wall of the test tube, and dried in a vacuum oven at 45°C for more than 2 hours.

[0066] S2 According to the total mass of the above-mentioned phospholipids, add a certain volume of buffer solution with a pH of 7.4 (containing 10% (volume ratio) glycerol, 10% (volume ratio) propylene glycol and 80% (volume ratio) 0.1M Tris Tris trihydroxyaminomethane) , the phospholipid mixture film was hydrated so that the final concentration of phospholipids was 3 mg / ml. Heat to above 70°C to make it fall off the wall of the test tube. Keep the water ...

Embodiment 2

[0086] Preparation of Hydrogen Microbubble Aqueous Solution

[0087] In S1, a certain amount of 1,2-docosyl fatty acylglyceryl phosphatidylcholine (22:0PC), polyethylene glycol 2000 modified 1,2-distearoyl Glycerylphosphatidylethanolamine (DSPE-PEG) was mixed in chloroform with a vortex mixer. The chloroform was removed with a dry nitrogen flow to form a uniform film of the dissolved material on the wall of the test tube, and dried in a vacuum oven at 45°C for more than 2 hours.

[0088] S2 According to the total mass of the above-mentioned phospholipids, add a certain volume of buffer solution with a pH of 7.4 (containing 10% (volume ratio) glycerol, 10% (volume ratio) propylene glycol and 80% (volume ratio) 0.1M Tris Tris trihydroxyaminomethane) , the phospholipid mixture film was hydrated so that the final concentration of phospholipids was 3 mg / ml. Heat to above 70°C to make it fall off the wall of the test tube. Keep the water temperature above 80°C with a water-bath...

Embodiment 3

[0094] Preparation of Hydrogen Microbubble Aqueous Solution

[0095] S1 A certain amount of 1,2-arachidylglycerylphosphatidylcholine (20:0, PC) and polyethylene glycol 2000 stearate (PEG40S) were mixed in chloroform with a vortex at a molar ratio of 85:15. Spin mixer to mix. The chloroform was removed with a dry nitrogen flow to form a uniform film of the dissolved material on the wall of the test tube, and dried in a vacuum oven at 45°C for more than 2 hours.

[0096] S2 According to the total mass of the above-mentioned phospholipids, add a certain volume of buffer solution with a pH of 7.4 (containing 10% (volume ratio) glycerol, 10% (volume ratio) propylene glycol and 80% (volume ratio) 0.1M Tris Tris trihydroxyaminomethane) , the phospholipid mixture film was hydrated so that the final concentration of phospholipids was 3 mg / ml. Heat to above 70°C to make it fall off the wall of the test tube. Keep the water temperature above 70°C with a water-bath ultrasonic oscilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com