Transplanting mechanism special for male parent two-line transplanting of hybrid rice seed production

A hybrid rice and male parent technology, applied in the field of agricultural machinery, can solve the problems of uneven spacing between seedlings, high labor intensity, poor straightness and parallelism of ridges and rows, and achieve uniform spacing between seedlings, high planting quality, and reduced movement. The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and example.

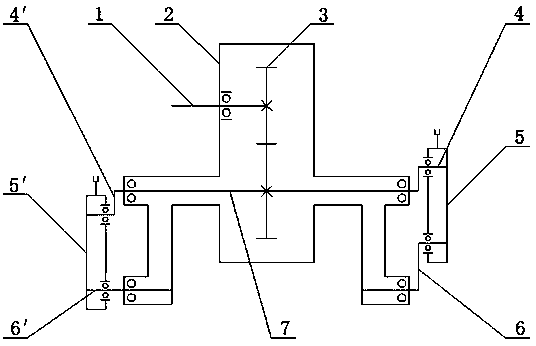

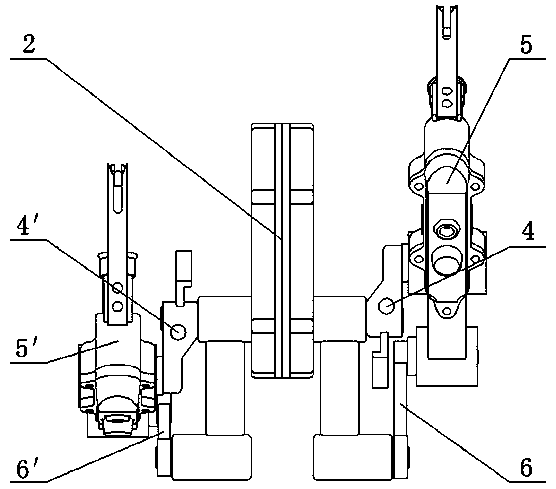

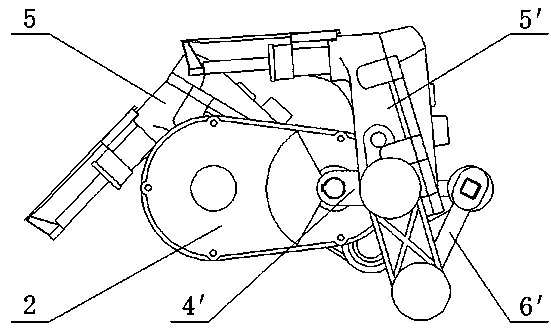

[0016] Such as figure 1 , 2 , shown in 3, 4, hybrid rice seed production male parent two rows transplanting special-purpose sub-insertion mechanism of the present invention, comprise transmission part, left sub-insertion mechanism and right sub-insertion mechanism; Transmission part comprises transmission shaft 1, gearbox body 2, Driving gear 3, gear shaft 7, transmission shaft 1 is installed on the front part of gearbox body 2 through bearing, driving gear 3 is fixed on the transmission shaft 1, gear shaft 7 is installed on the middle part of gearbox body 2 through bearing, driving gear 3 It forms a gear transmission with the gear shaft 7, the rear end of the left crank shaft 4' of the left split mechanism 5' is fixed on the left end of the gear shaft 7, and the rear end of the left rocker shaft 6' of the left split mechanism 5' is installed through a bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com