Electrode active material, preparation method thereof, and electrode and lithium battery containing the same

A technology of electrode active material and lithium oxide, which can be used in non-aqueous electrolyte batteries, electrode manufacturing, lithium batteries, etc., and can solve problems such as battery performance deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0128] Preparation Example 1 (dry process)

[0129] Tin oxide (SnO) and zinc oxide (ZnO) were mixed in a molar ratio of about 1:2 and milled in a planetary ball mill (Fritsch, Planetary mono mill 6) at about 300 to about 500 rpm for about 5 hours. Subsequently, SnZn having a spinel structure was prepared by sintering the resultant at about 1200°C for about 48 hours in an air atmosphere. 2 o 4 . Then, by using a paint shaker (paint shaker) to SnZn 2 o 4 SnZn with a diameter of about 100 nm was prepared by grinding for about 1 hour 2 o 4 nanoparticles.

[0130] figure 2 Shows that the SnZn prepared in Preparation Example 1 2 o 4 Scanning electron microscope (SEM) image of nanoparticles.

Embodiment 1

[0135] SnO and ZnO were mixed at a molar ratio of about 1:2, and then milled in a planetary ball mill (Fritsch, Planetary mono mill 6) at about 300 to about 500 rpm for about 5 hours. Subsequently, SnZn having a spinel structure was prepared by sintering the resultant at about 1200°C for about 48 hours in an air atmosphere. 2 o 4 . Then, by using a paint shaker to mix the SnZn 2 o 4 SnZn with a diameter of about 100 nm was prepared by grinding for about 1 hour 2 o 4 nanoparticles.

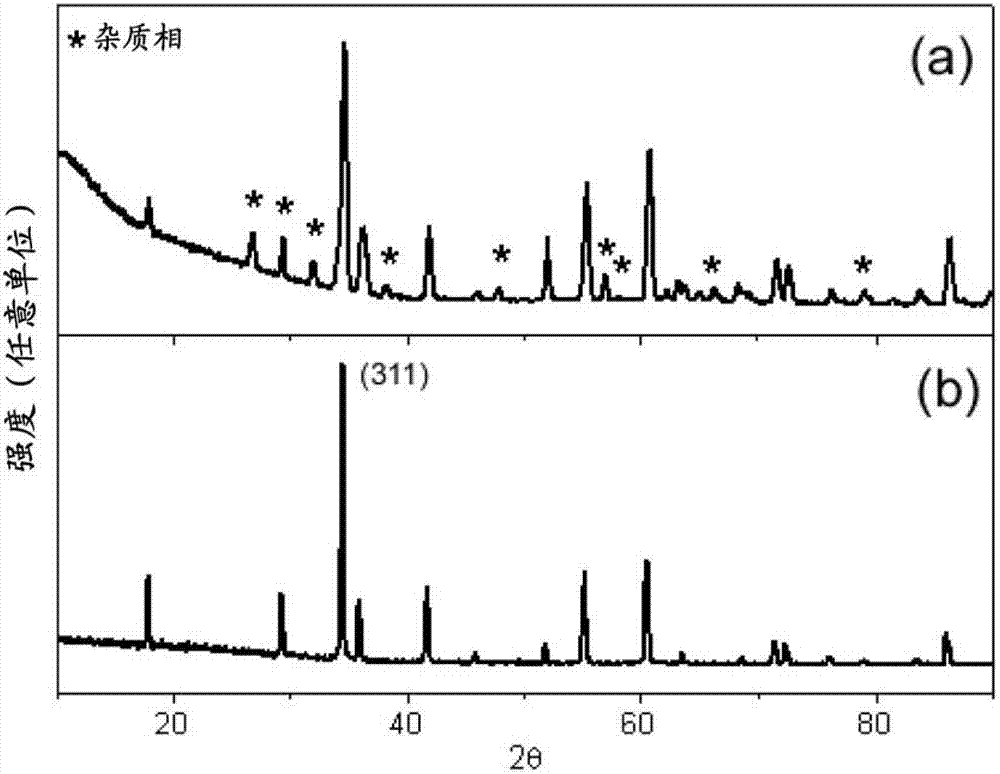

[0136] 3 parts by weight of the SnZn 2 o 4 Nanoparticles and 97 parts by weight of LiNi with an average particle size of 10 μm 0.5 mn 1.5 o 4 Powder mix. The LiNi with an average particle size of 10 μm 0.5 mn 1.5 o 4 powder shown in image 3 middle. The LiNi 0.5 mn 1.5 o 4 On-nucleus formation including SnZn 2 o 4 Positive active material of the surface treatment layer: the mixture was placed in a dry surface treatment device (Hosokawa Micron Corporation, Japan, Mechanofusion d...

Embodiment 2

[0138] The positive active material was fabricated using the same method as in Example 1, except that SnO and magnesium oxide (MgO) were used as lithium-free oxide precursors to form 2 o 4 outside the surface treatment layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com