Integral inclined pin-fin tube

A technology of slanted needles and finned tubes, applied in the field of heat exchange elements, can solve the problems of not being able to promote the discharge of condensate, and achieve the effect of avoiding corrosion problems and eliminating stagnation zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

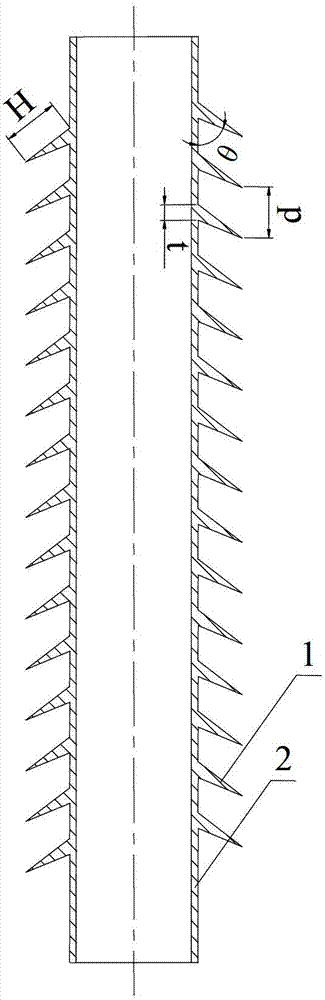

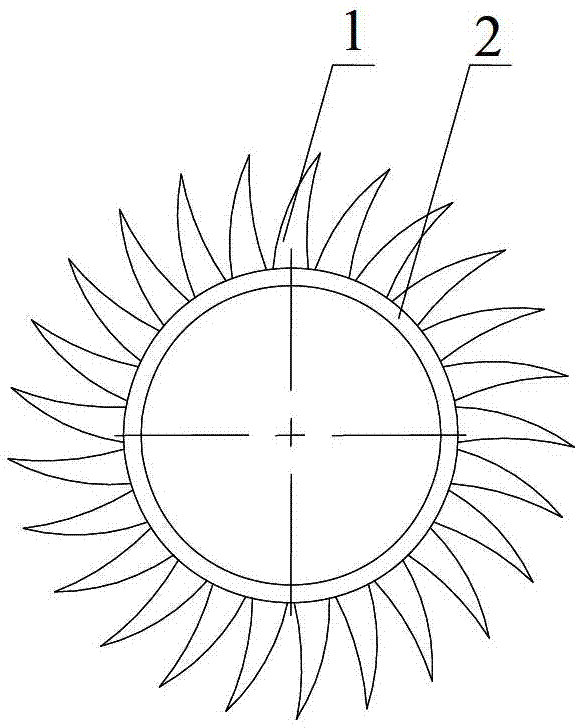

[0024] to combine figure 1 and figure 2 , the overall oblique pin-fin tube is composed of the base tube 2 and the pin-fin 1, and the axial angle θ between the pin-fin 1 and the base tube 2 is less than 90°.

[0025] The integral slanted pin-fin tube is based on a smooth round tube, and the pin-fin 1 is directly processed on the outer surface of the smooth tube by using a continuous cutting method. The pin fins 1 are arranged on the outer surface of the base tube 2 with a certain pitch p. According to the needs of the service conditions, the needle fin 1 can be designed and processed into different heights H, different pitches p, different root thicknesses t and different angles θ.

[0026] When the steam contains a lot of air, the basic parameters of the slanted pin-fin tube are: the outer diameter of the base tube is 25-50mm, the wall thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com