A production process of top-quality down and down and down and down screening device

A screening device and suspending velvet technology, which are applied in the fields of fiber separation, textile and papermaking, fiber processing, etc., can solve the problems of unseen suspending velvet production process, inability to industrialize production, low efficiency, etc., and achieve high added value, The effect of large market demand and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

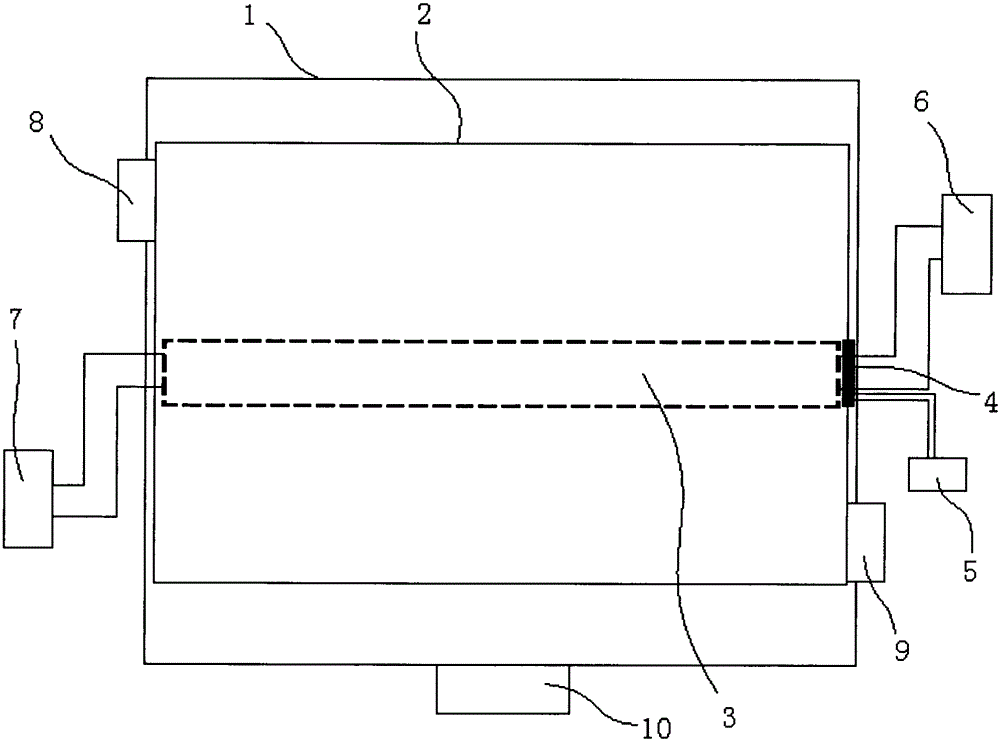

[0025] As a preferred embodiment of the present invention, please refer to figure 1 , The hanging velvet screening device has a screening box 1, and the screening box 1 is provided with a trommel 2, and the middle part of the trommel 2 is provided with a blowing leak pipe 3, and the center line of the trommel 2 coincides with the blowing leak pipe 3.

[0026] The two ends of the trommel 2 are connected with the drive motor 5 through the rolling shaft 4, and the trommel 2 is composed of stainless steel wires criss-crossing, thereby having a screen hole with an aperture of 13×1.5mm (rectangular hole), and the two sides of the trommel 2 are respectively set There are eider down feeding port 8 and hanging velvet feeding port 9.

[0027] The two ends of blowing leak pipe 3 are respectively connected with blower 6 and blower 7, and the surface of blowing leak pipe 3 is evenly distributed with air leakage holes, and the aperture of air leakage holes is 5mm.

[0028] The side end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com