Heat treatment PAG water base quenching medium stabilizer and uses thereof

A water-based quenching and stabilizer technology, applied in quenching agents, heat treatment equipment, manufacturing tools, etc., can solve problems such as polluted water sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

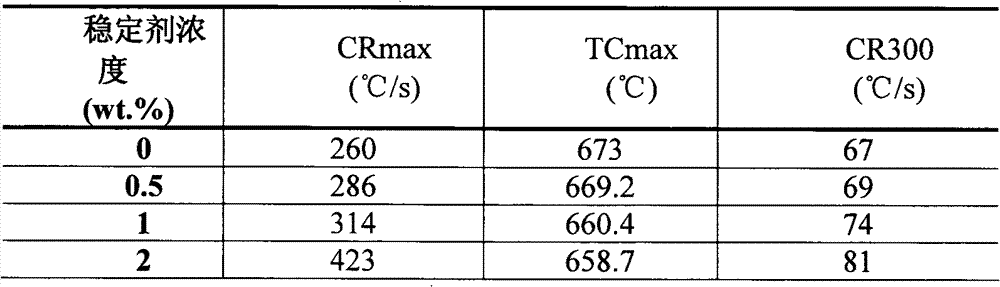

[0011] In the PAG quenching solution with a mass percentage concentration of 5%, add the following components by weight and stir and mix to form a stabilizer: 3 parts of foam-breaking polysiloxane solution, 5 parts of diisobutyl ketone, alkenyl succinic acid- 7 parts of zinc naphthenate, 2 parts of barium sulfonate and 2 parts of polyethylene glycol. The test results of the prepared quenching liquid using a cooling characteristic tester are shown in Table 1, wherein 1% is the optimal ratio, and the service life is increased by 20%.

[0012] Table 1 Effect of stabilizer addition amount on PAG5 cooling characteristics

[0013]

Embodiment 2

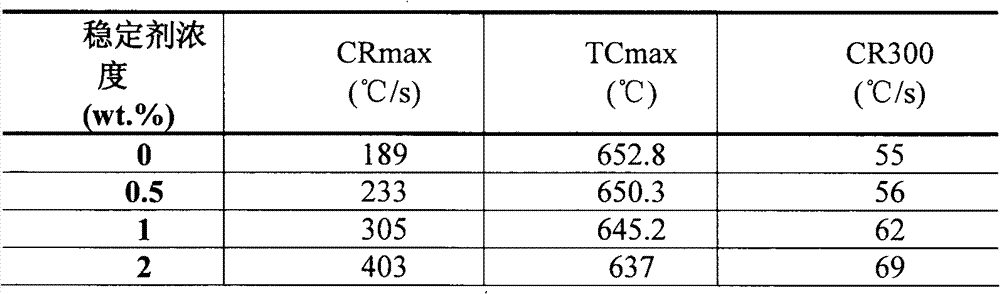

[0015] In the PAG quenching solution with a mass percentage concentration of 10%, add the following components by weight and stir and mix to form a stabilizer: 1 part of foam-breaking polysiloxane solution, 3 parts of diisobutyl ketone, alkenyl succinic acid- 4 parts of zinc naphthenate, 2 parts of barium sulfonate and 3 parts of polyethylene glycol. The test results of the prepared quenching liquid using a cooling characteristic tester are shown in Table 2, wherein 0.5% is the optimal ratio, and the service life is increased by 16%.

[0016] Table 2 Effect of stabilizer addition amount on PAG10 cooling characteristics

[0017]

Embodiment 3

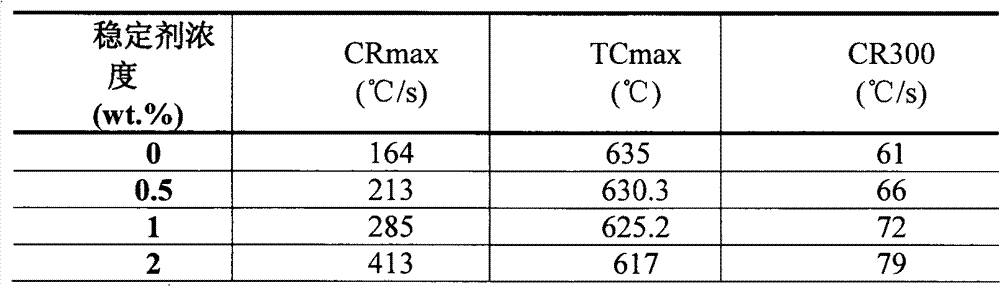

[0019] In the PAG quenching solution with a concentration of 10% by mass of PAG, add the following components by weight and stir and mix to form a stabilizer: 4 parts of foam-breaking polysiloxane solution, 6 parts of diisobutyl ketone, alkenyl succinic acid-cyclic 7 parts of zinc alkanoate, 4 parts of barium sulfonate and 5 parts of polyethylene glycol. The test results of the prepared quenching liquid using the cooling characteristic tester are shown in Table 3, wherein 1% is the optimal ratio, and the service life is increased by 21%.

[0020] Table 3 The effect of the amount of stabilizer added on the cooling characteristics of PAG15

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com