Leather comprehensive fat liquor and preparation method of the same

A fatliquor, leather technology, applied in leather impregnation, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Large, poor stability and other problems, to achieve the effect of good softness and fullness, improved softness and hand feel, and good appearance and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

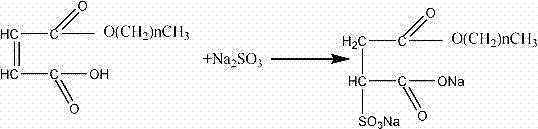

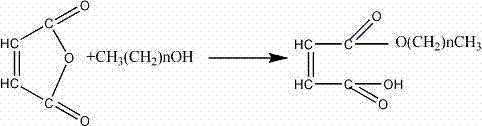

[0022] 1. Set the mass ratio to C 8 -C 10 Alcohol:C 12 -C 14 Alcohol:C 16 -C 18 Alcohol=8%:80%:12% mixed higher carbon alcohol and maleic anhydride are mixed in a molar ratio of 1:1, and reacted at 100°C for 6 hours to obtain a mixed higher carbon alcohol ester; then mixed higher carbon alcohol Alcohol esterification and anhydrous sodium sulfite were added into anhydrous sodium sulfite at a molar ratio of 1:1, and reacted at 85°C for 4 hours to obtain esterified sulfitated products of higher alcohols.

[0023] 2. The esterification sulfitation product of the above-mentioned high carbon alcohol is cooled to 60 ℃, and is measured by mass ratio: the esterification sulfitation product of high carbon alcohol: modified soybean lecithin: sulfited rapeseed oil: lanolin : Natural beef hoof oil: No. 10 white oil: Sodium lauryl sulfate: water = 22:12:12:2:2:3:1:46 Add the compound ingredients, stir for 1 hour and then use saturated sodium hydroxide Adjust the pH value of the aqueou...

Embodiment 2

[0025] 1. The mass ratio is: C 8 -C 10 Alcohol:C 12 -C 14 Alcohol:C 16 -C 18 Alcohol=12%:80%:8% mixed higher carbon alcohol and maleic anhydride are mixed in a molar ratio of 1:0.8, and reacted at 100°C for 6 hours to obtain a mixed higher carbon alcohol ester; then mixed higher carbon alcohol Alcohol and sodium metabisulfite were added into sodium metabisulfite at a molar ratio of 1:0.4, and reacted at 80°C for 4 hours to obtain esterified sulfitated products of higher alcohols.

[0026] 2. The esterification sulfitation product of the above-mentioned high carbon alcohol is cooled to 60 ℃, and is measured by mass ratio: the esterification sulfitation product of high carbon alcohol: modified soybean lecithin: sulfited rapeseed oil: lanolin : Natural beef hoof oil: No. 10 white oil: Sodium lauryl sulfate: Water = 27:12:6:1:1:4:1:48 Add compound ingredients, stir for 1 hour and then use saturated sodium hydroxide Adjust the pH value of the aqueous solution to 6-8, stir for...

Embodiment 3

[0028] 1. The mass ratio is: C 8 -C 10 Alcohol:C 12 -C 14 Alcohol:C 16 -C 18 Alcohol=15%:75%:10% mixed higher alcohol alcohol and maleic anhydride are mixed at a molar ratio of 1:0.6, and reacted at 150°C for 2 hours to obtain a mixed higher alcohol ester; then mixed higher alcohol Alcohol and anhydrous sodium sulfite were added into anhydrous sodium sulfite at a molar ratio of 1:0.6, and reacted at 80°C for 4 hours to obtain esterified sulfitated products of higher alcohols.

[0029] 2. The esterification sulfitation product of above-mentioned high carbon alcohol is cooled to 60 ℃, is the esterification sulfitation product of high carbon alcohol with mass ratio: modified soybean lecithin: sulfitated rapeseed oil: lanolin: natural Bovine hoof oil: No. 10 white oil: sodium lauryl sulfate: water = 25:12:8:2:2:3:1:47, add the compound ingredients, stir for 1 hour and adjust with saturated sodium hydroxide aqueous solution When the pH value reaches 6-8, stir for 0.5 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com