Rustproof lubricating agent

A technology of anti-rust lubricant and anti-corrosion agent, which is applied in the direction of lubricating composition and petroleum industry, etc. It can solve the problems of not being suitable for automatic cleaning machines, etc., and achieve the effect of preventing corrosion, reducing corrosion and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

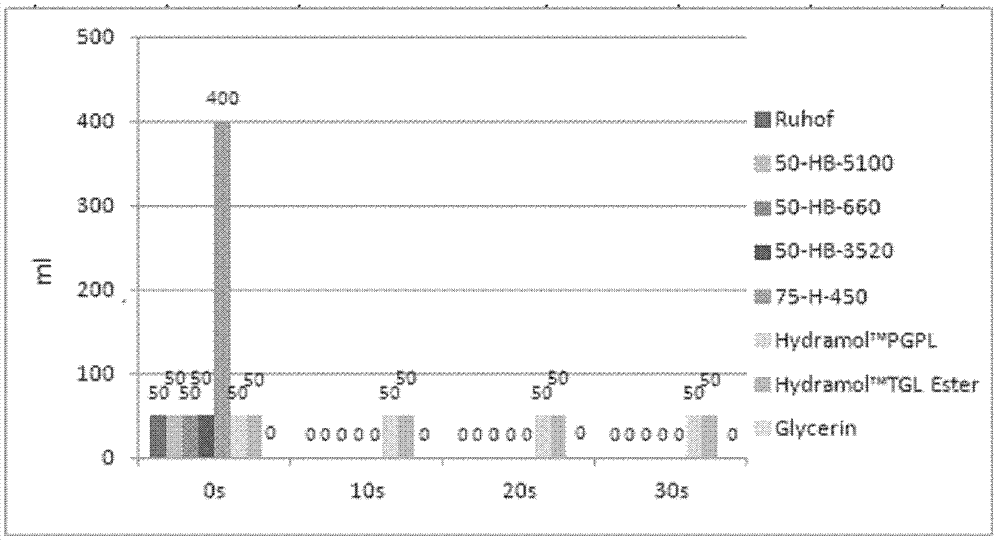

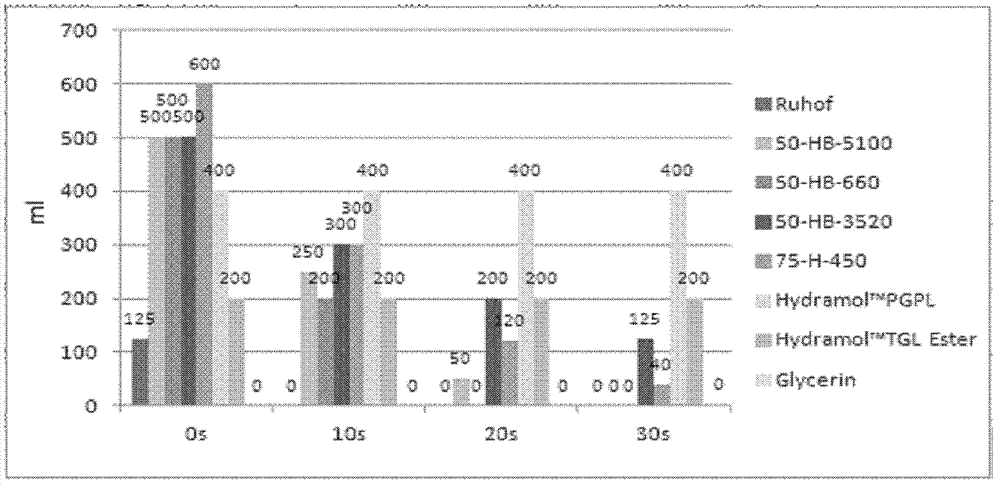

[0052] A. Bubble level test

[0053] Since lubricants are to be used in automatic cleaning machines, it is preferable to choose a formulation with low foaming ingredients. Use the foam level test (STM 100) to carry out the base oil screening test.

[0054] 1) Dilute 5% oil solution with distilled water at 25°C or 60°C at 1:200;

[0055] 2) Put the diluted solution into the beaker and record the initial height of the solution (record the volume value marked in ml as the height, and the appropriate final volume is 500 ml);

[0056] 3) Mix the solution in a blender (Philips Comfort) at high speed for 20 seconds;

[0057] 4) Stop stirring and record the height of the solution foam at 0, 10, 20 and 30 seconds respectively;

[0058] 5) Calculate the height of the foam:

[0059] Foam height = total height at the time of recording-initial solution height.

[0060] The preferred base oil is that the foam height is less than 50ml in 20 seconds.

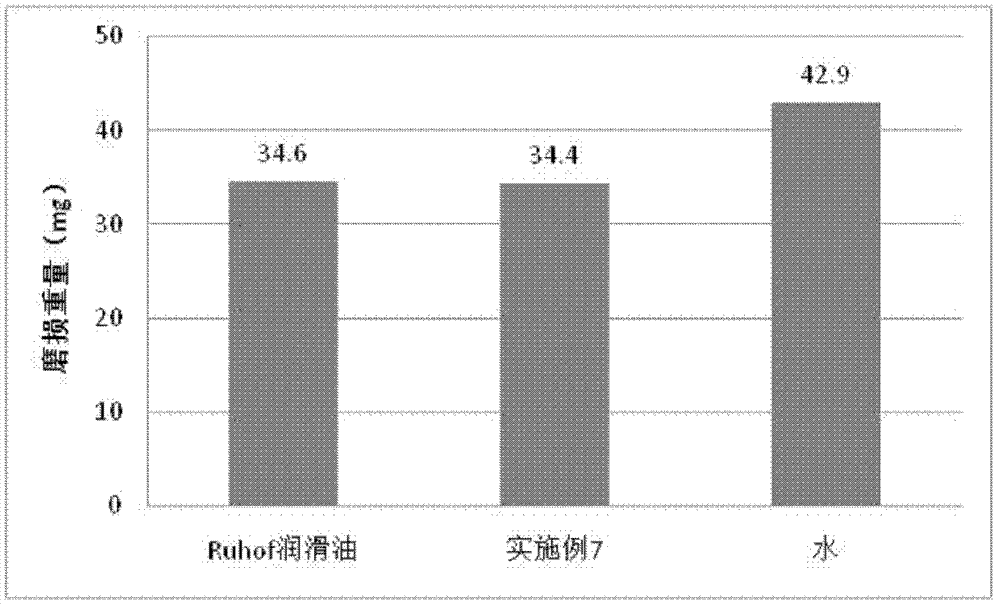

[0061] Table 1 shows the base oils evaluated in the p...

Embodiment 1

[0072]

Embodiment 2

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com