High-detergency hydraulic oil composition

A technology of hydraulic oil composition and detergency, applied in lubricating compositions, petroleum industry, etc., can solve the problems of rising operating temperature, poor heat transfer effect, affecting valve response speed, etc., and achieve the effect of keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

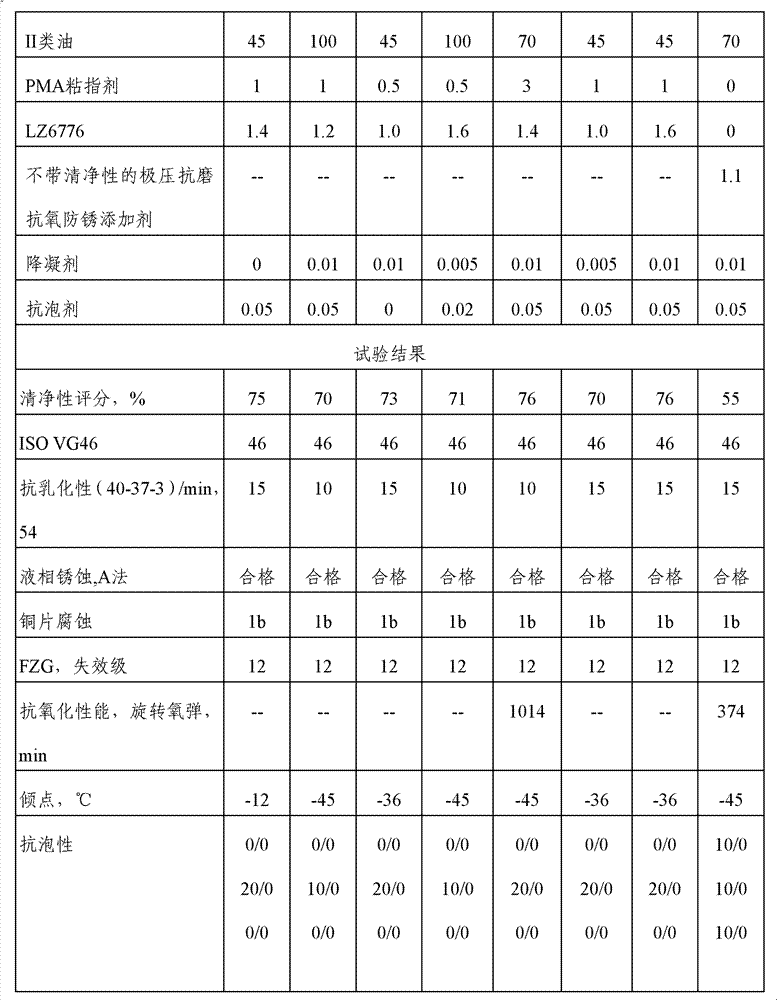

Examples

Embodiment 1

[0032] The components of the hydraulic oil composition in this embodiment are: 55 kg of type I oil, 45 kg of type II oil, 1 kg of PMA viscosity index agent, 1.4 kg of LZ6776, 0.01 kg of pour point depressant, and 0.050 g of antifoaming agent.

[0033] Among them, 150SN is used for type I oil; II4 base oil produced by Shanghai Gaoqiao is used for type II oil; LZ7720C is used for PMA type viscosity index improver; LZ7749B is used for pour point depressant; Produced by Borun Company.

[0034] The preparation process is as follows: mixing each component according to the above ratio, heating to keep the temperature at 45°C, and stirring at the same time, and the stirring time is controlled at 2 hours.

Embodiment 2

[0036] The components of the hydraulic oil composition in this embodiment are: 100 kg of type II oil, 1 kg of PMA viscosity index agent, 1.2 kg of LZ6776, and 0.050 g of antifoaming agent.

[0037] Among them, the II6 base oil produced by Shanghai Gaoqiao was used as the II type oil; the PMA type viscosity index improver was Viscoplex 8-200; the pour point depressant was Empicryl PPT148; the antifoaming agent was 1# composite antifoaming agent.

[0038] The preparation process is as follows: mixing each component according to the above-mentioned ratio, heating to keep the temperature at 50°C, and stirring at the same time, and the stirring time is controlled at 1.5 hours.

Embodiment 3

[0040] The components of the hydraulic oil composition in this embodiment are: 55 kg of type I oil, 45 kg of type II oil, 0.5 kg of PMA viscosity index agent, 1.0 kg of LZ6776, 0.01 kg of pour point depressant, and 0.050 g of antifoaming agent.

[0041] Among them, 500SN is used as the type I oil, and II6 base oil produced by Shanghai Gaoqiao is used as the type II oil; Viscoplex 8-310 is the viscosity index improver of the PMA type; Viscoplex 1-156 is the pour point depressant; foaming agent.

[0042] The preparation process is as follows: mixing each component according to the above-mentioned ratio, heating to keep the temperature at 50°C, and stirring at the same time, and the stirring time is controlled at 1.5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com