Delayed coking method

A delayed coking method and mixed liquid phase technology, applied in the field of carbonization or coking process, can solve the problems of reducing foam layer, reducing coke yield, etc., to reduce volume, increase light oil yield, save operating costs and Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0055] The present invention is illustrated below with specific examples, but the scope of the present invention is not limited.

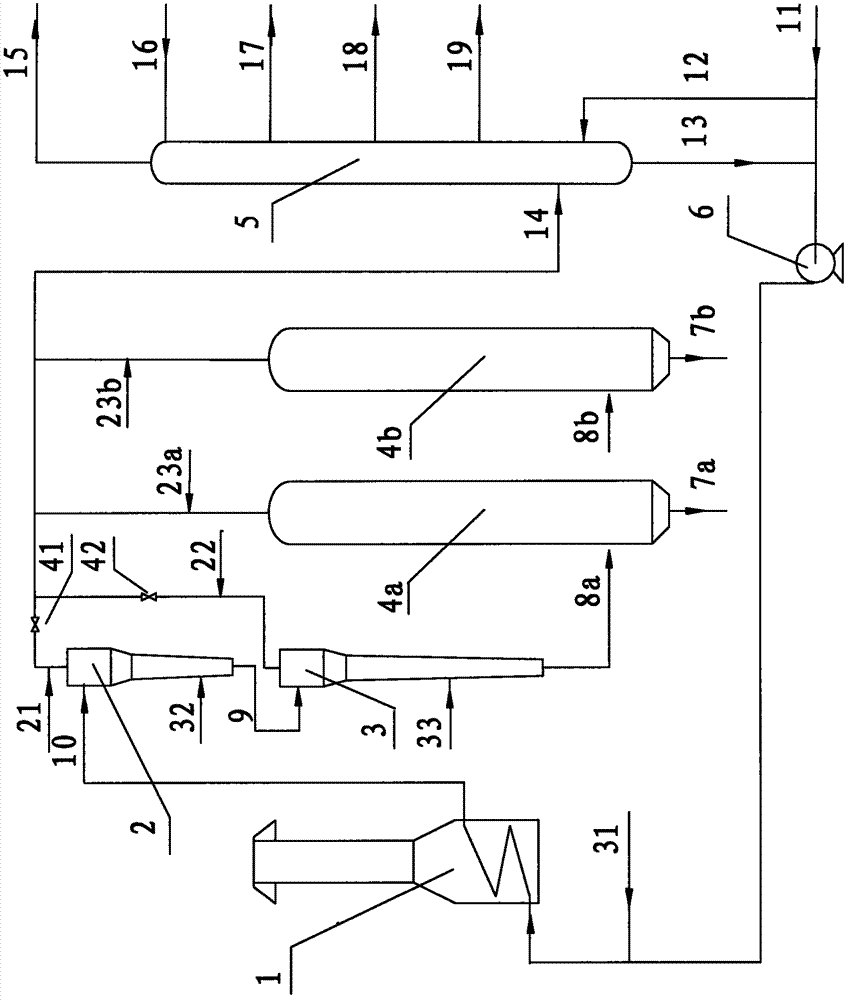

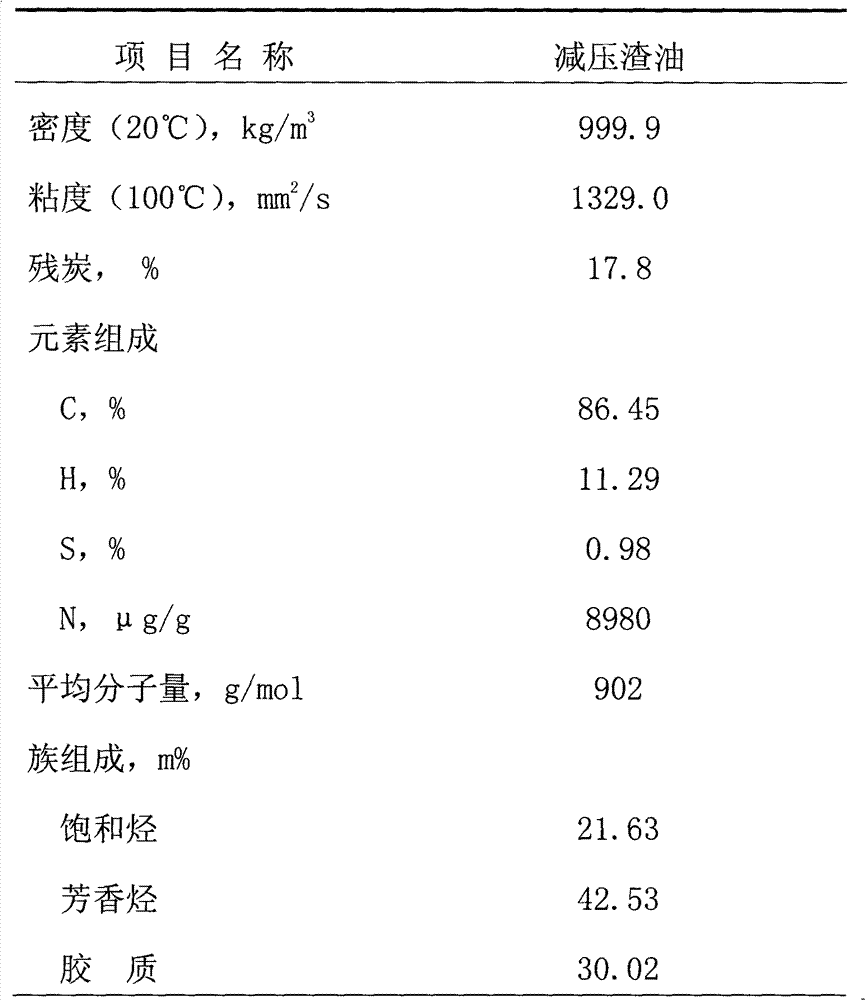

[0056] Four groups of tests were carried out on the medium-scale delayed coking test device, namely Examples 1 to 3 and Comparative Examples. For the flow chart of the test device, see figure 1 . Comparative test with figure 1 The difference of the flow shown is that no hydrocyclone is provided, and the hot stream flows out of the heating furnace 1 and directly enters the first coke tower 4a or the second coke tower 4b. The raw oil 11 used in Comparative Example, Example 1, Example 2 and Example 3 is the same residual oil feed, its properties are shown in Table 1, and the feed rate is 6kg / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com