Flaw-detecting, edge-milling and pre-bending unit for straight slit steel pipe

A technology of pre-bending and steel pipes, which is applied in the field of straight seam steel pipe flaw detection and edge milling pre-bending units, can solve the problems of high production costs, large equipment investment, small roller spacing and large quantities, etc., to save investment and operating costs, and have a high degree of automation , good coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

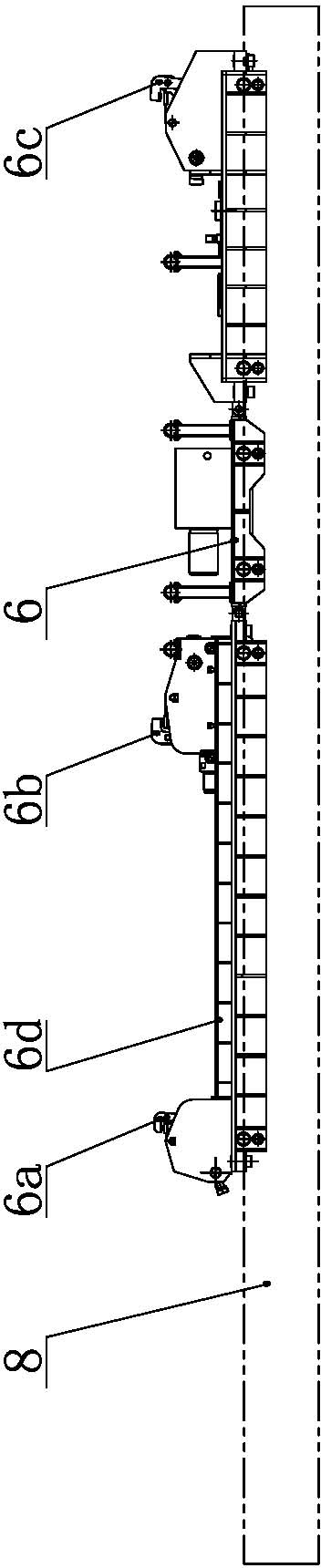

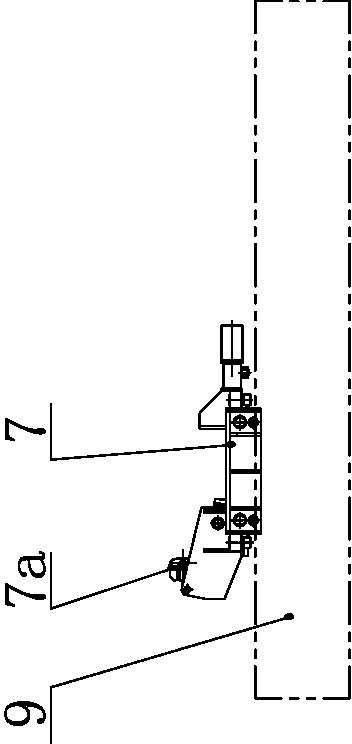

[0019] Such as Figures 1 to 4 The straight seam steel pipe flaw detection and edge milling pre-bending unit shown in the figure includes two passive roller tables 4 arranged parallel to each other, a hydraulic system 10 and an electrical automation control system 11, and the two passive roller tables 4 are connected from the feed end to the discharge A flaw detection device 1, a milling device 2, and a pre-bending device 3 are arranged in turn at the end, and a flaw detection head that can move laterally is arranged on the flaw detection device 1. Correspondingly, there are two sets of bending dies 3a and 3b driven by oil cylinders, a milling device 2, a pre-bending device 3, a first centering device 5a, a second centering device 5b, a third centering device 5c, and a fourth centering device. The centering device 5d is provided with a screw drive mechanism, the first centering device 5a, the second centering device 5a, the second centering device 5a, the second Centering dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com