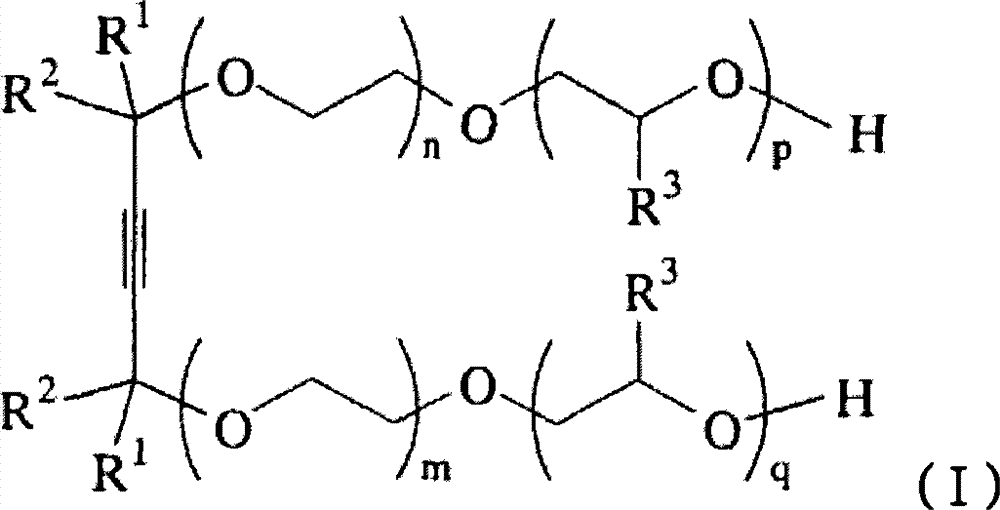

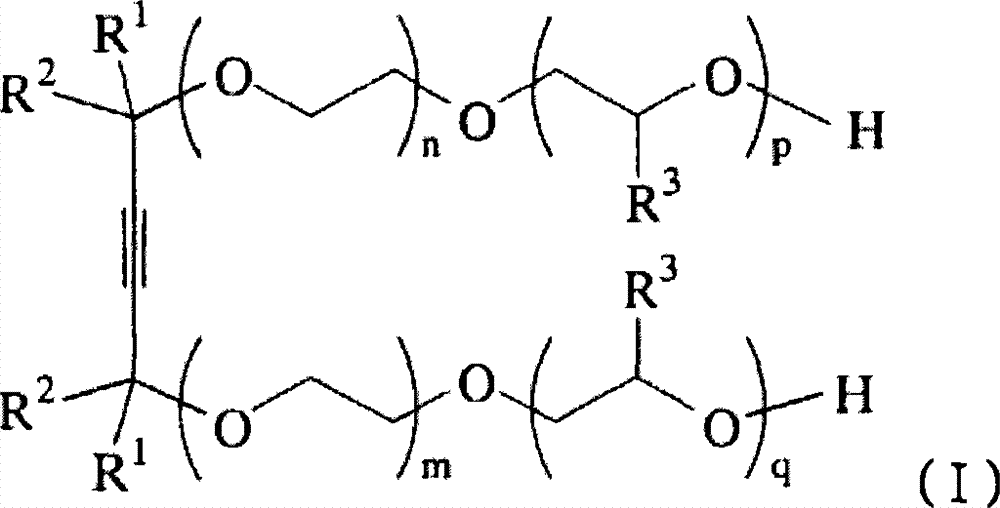

Surfactant Composition, Coating Solution Containing The Surfactant Composition, And Rubber Article Treated By The Coating Solution

A technology of surfactant and composition, applied in the field of coating of rubber products and surfactant composition, can solve the problem of not disclosing the use of rubber products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] Next, the present invention is described in further detail by referring to the following Preparation Examples, Examples and Comparative Examples, which by no means limit the scope of the present invention. In the following Preparation Examples, Examples and Comparative Examples, parts and % are parts by weight and % by weight, respectively.

[0083] Preparation Example

[0084]7.5 parts of 2-ethylhexyl glycidyl ether-capped acetylenic glycol ethoxylates that had been heated to 70° C. were placed in a container equipped with a propeller stirrer, and 92.5 parts of the formula (7) The indicated silicone surfactant was added gradually. After stirring the mixture continuously for 2 hours, the mixture was cooled to room temperature. After cooling, the mixture was filtered through a filter cloth (200 mesh) to obtain a surfactant composition (hereinafter referred to as M-1).

[0085] Surfactant compositions M-2 to M-14 were obtained by repeating the above steps by using the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com