Preparation method of anti-reflection self-cleaning coated glass

A coated glass and self-cleaning technology, which is applied in the field of preparation of anti-reflection and self-cleaning coated glass, can solve the problems of poor UV aging resistance, unsatisfactory self-cleaning effect, and inability to achieve super-hydrophilicity, etc., and achieve UV aging resistance Excellent, improve the visible light transmittance, reduce the temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention relates to a kind of preparation method of anti-reflection self-cleaning coated glass, which comprises the following steps:

[0024] Step 1. Preparation of SiO 2 -TiO 2 Composite sol: nano-SiO 2 Sol and Nano TiO 2 The sol is mixed according to the silicon-titanium molar ratio of 1:5-30, stirred evenly, then an acid catalyst is added dropwise to adjust the pH value of the mixed sol to 2-4, and the stirring is continued to obtain the SiO 2 -TiO 2 Composite sol;

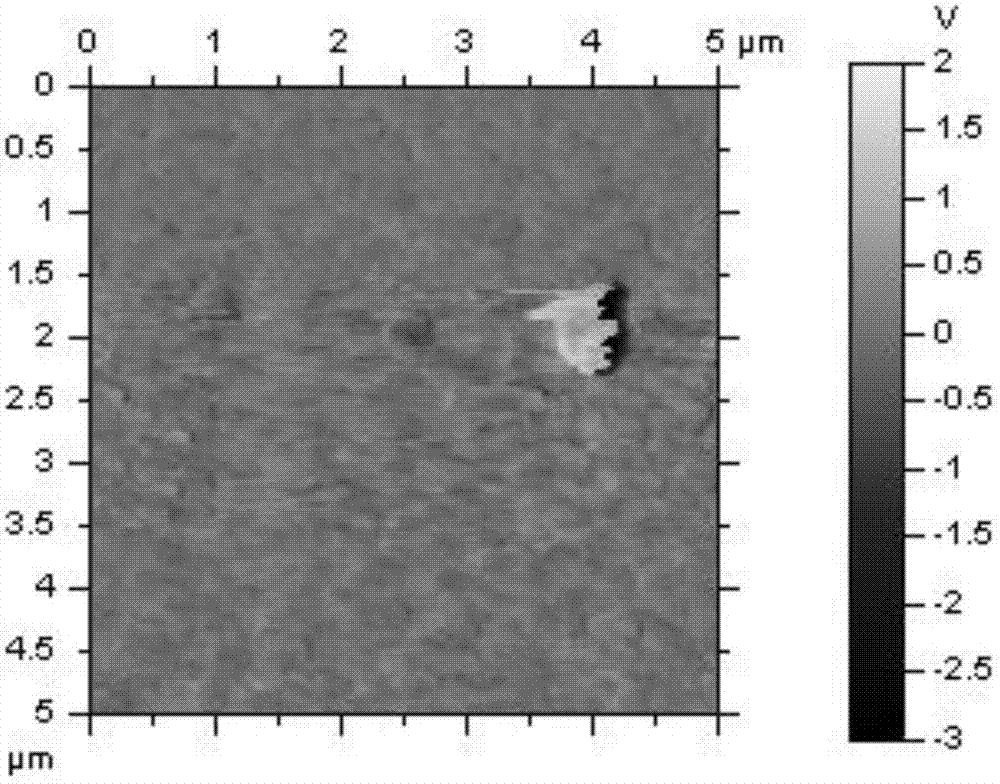

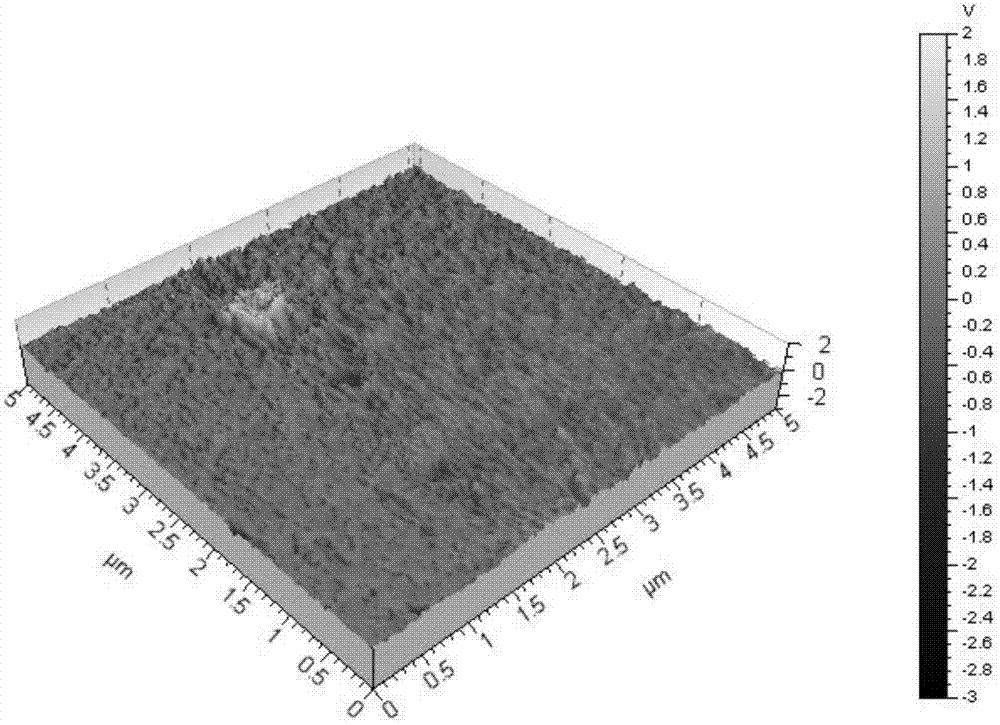

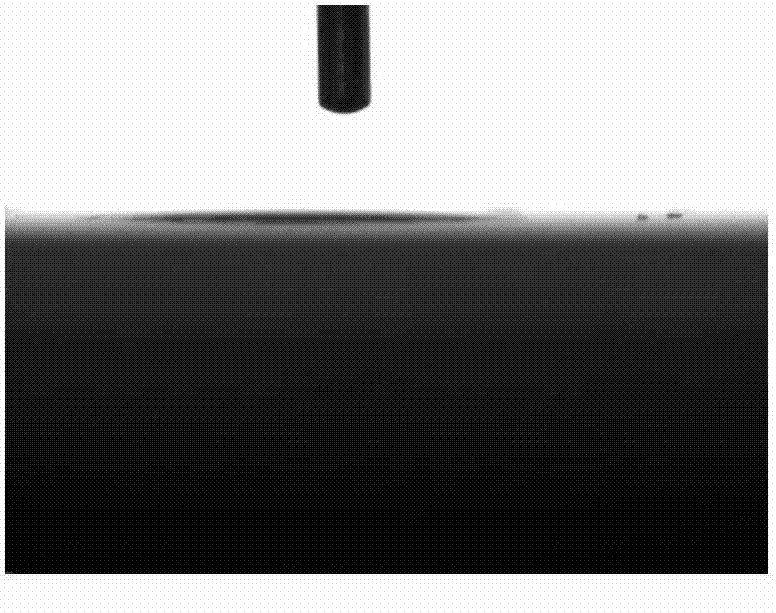

[0025] Step 2. Coating by pulling method: first put the clean glass substrate on the pulling machine, and then put the glass substrate on the SiO 2 -TiO 2 After fully immersing in the composite sol for 5-20 minutes, pull it up at a pulling rate of 1-20cm / min, and then let the glass substrate with the wet film attached to it dry at room temperature for 10-20 minutes, and the surface of the glass substrate forms a The layer has a roughness nano film layer;

[0026] Step 3. Post-treatme...

Embodiment 1

[0028] Step 1. Preparation of TiO 2 Sol:

[0029] Anatase TiO 2 The powder is completely dissolved in deionized water, anatase TiO 2 The molar ratio of powder to deionized water is 1:5 to obtain the TiO 2 Sol;

[0030] Step 2. Preparation of SiO 2 Sol:

[0031] Weigh tetraethyl orthosilicate, absolute ethanol, deionized water and acid catalyst (30% nitric acid aqueous solution) with a molar ratio of 1:15:1:0.001, dilute ethyl orthosilicate with absolute ethanol, The mixed solution of acid catalyst and deionized water was added dropwise, the above mixed solution was stirred and reacted for 4 hours at 20°C, and then aged for 1 day, and the reacted mixed solution was diluted 1.2 times with additional absolute ethanol to obtain The SiO 2 Sol, spare;

[0032] Step 3. Preparation of SiO 2 -TiO 2 Composite sol:

[0033] nano-SiO 2 Sol and Nano TiO 2 The sol is mixed according to the silicon-titanium molar ratio of 1:5, stirred evenly, and then an acid catalyst (30% nitri...

Embodiment 2

[0039] Step 1. Preparation of TiO 2 Sol:

[0040] Anatase TiO 2 The powder is completely dissolved in deionized water, anatase TiO 2 The molar ratio of powder to deionized water is 1:30 to obtain the TiO 2 Sol;

[0041] Step 2. Preparation of SiO 2 Sol:

[0042] Weigh tetraethyl orthosilicate, absolute ethanol, deionized water and acid catalyst (20% sulfuric acid aqueous solution) with a molar ratio of 1:30:5:0.01, dilute ethyl orthosilicate with absolute ethanol, drop Add the mixed solution of acid catalyst and deionized water, ultrasonically react the above mixed solution at 30°C for 20 minutes, let it stand for aging for 2 days, and then dilute the reacted mixed solution by 0.8 times with additional absolute ethanol to obtain the obtained SiO 2 Sol, spare;

[0043] Step 3. Preparation of SiO 2 -TiO 2 Composite sol:

[0044] nano-SiO 2 Sol and Nano TiO 2 The sol is mixed according to the silicon-titanium molar ratio of 1:30, stirred evenly, and then an acid cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com