Environmentally friendly and clean process method for producing hydrocyanic acid derivatives by utilizing purge gas

A process method, the technology of hydrocyanic acid, applied in the directions of metal cyanide, inert gas compound, chemical instrument and method, etc., can solve the problem of not giving full play to the value of comprehensive utilization of purge gas, and achieve good economic and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

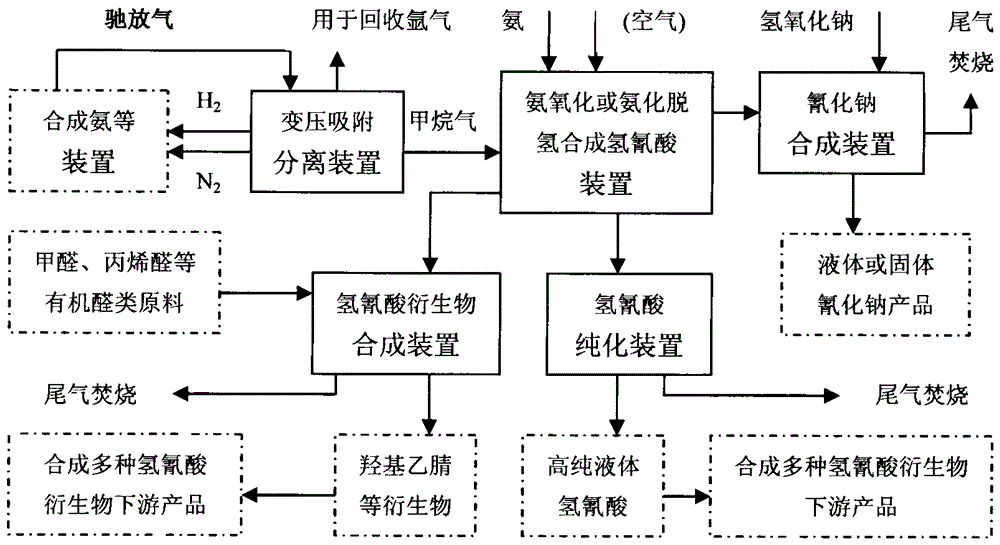

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: The purge gas of synthetic ammonia is separated by pressure swing adsorption and other auxiliary separation devices to obtain H 2 , NH 3 , N 2 、CH 4 and exhaust gas; H 2 , NH 3 , N 2 Respectively enter the ammonia synthesis system for recycling, the tail gas is used to recover Ar, CH 4 It is used for the synthesis of hydrocyanic acid by Angle's ammoxidation.

[0041] The purge gas is separated to give CH 4 (methane gas) composition:

[0042] serial number

[0043] CH 4 (Methane gas) Synthesis gas is obtained through Angle's ammoxidation synthesis reaction, and the composition of the synthesis gas is as follows:

[0044] serial number

[0045] The synthesis gas is directly absorbed and reacted by sodium hydroxide aqueous solution without going through the ammonia removal process to obtain a high-purity sodium cyanide aqueous solution, and free ammonia remains in the tail gas; the quality table of the sodium cyanide aqueous solut...

Embodiment 2

[0060] Embodiment 2: same as embodiment 1, utilize above-mentioned synthetic ammonia to purge gas separation and obtain CH 4 (Methane gas) Synthesis gas is obtained through Angle's ammoxidation synthesis reaction; reaction synthesis gas is obtained through joint removal of ammonia to obtain reaction synthesis gas without ammonia or containing constant ammonia; synthesis gas after ammonia removal is absorbed by formaldehyde solution to obtain high-purity hydroxyl Acetonitrile aqueous solution, used to synthesize high-purity hydrocyanic acid derivatives.

[0061] The composition of the synthesis gas is as follows:

[0062] serial number

component name

Component ratio%

serial number

component name

Component ratio%

1

HCN

8.092

6

N 2

54.328

2

NH 3

1.508

7

CO 2

0.503

3

h 2 o

25.513

8

CO

4.705

4

CH 4

0.462

9

H 2

4.765

5

O 2

0.020

10

othe...

Embodiment 3

[0072] Embodiment 3: same as embodiment 2, utilize above-mentioned synthetic ammonia to purge gas separation and obtain CH 4 (Methane gas) Synthesis gas is obtained through Angle's ammoxidation synthesis reaction; reaction synthesis gas is obtained through joint removal of ammonia to obtain reaction synthesis gas without ammonia or containing constant ammonia; synthesis gas after ammonia removal is absorbed by deionized water to obtain hydrogen cyanide The acid aqueous solution is refined to obtain high-purity liquid hydrocyanic acid, which is used for the synthesis of hydrocyanic acid derivatives; absorbing tail gas and sending it to the tail gas incineration device for incineration. The quality that obtains high-purity liquid hydrocyanic acid is as follows:

[0073] Hydrocyanic acid (%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com