Compressed air nail-shooting gun

A compressed air and nail gun technology, applied in the field of nail guns, can solve the problems of low nailing efficiency, narrow application range, and broken nail guns, so as to reduce the probability of safety accidents, low-carbon environmental protection scope, Effect of small intake pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

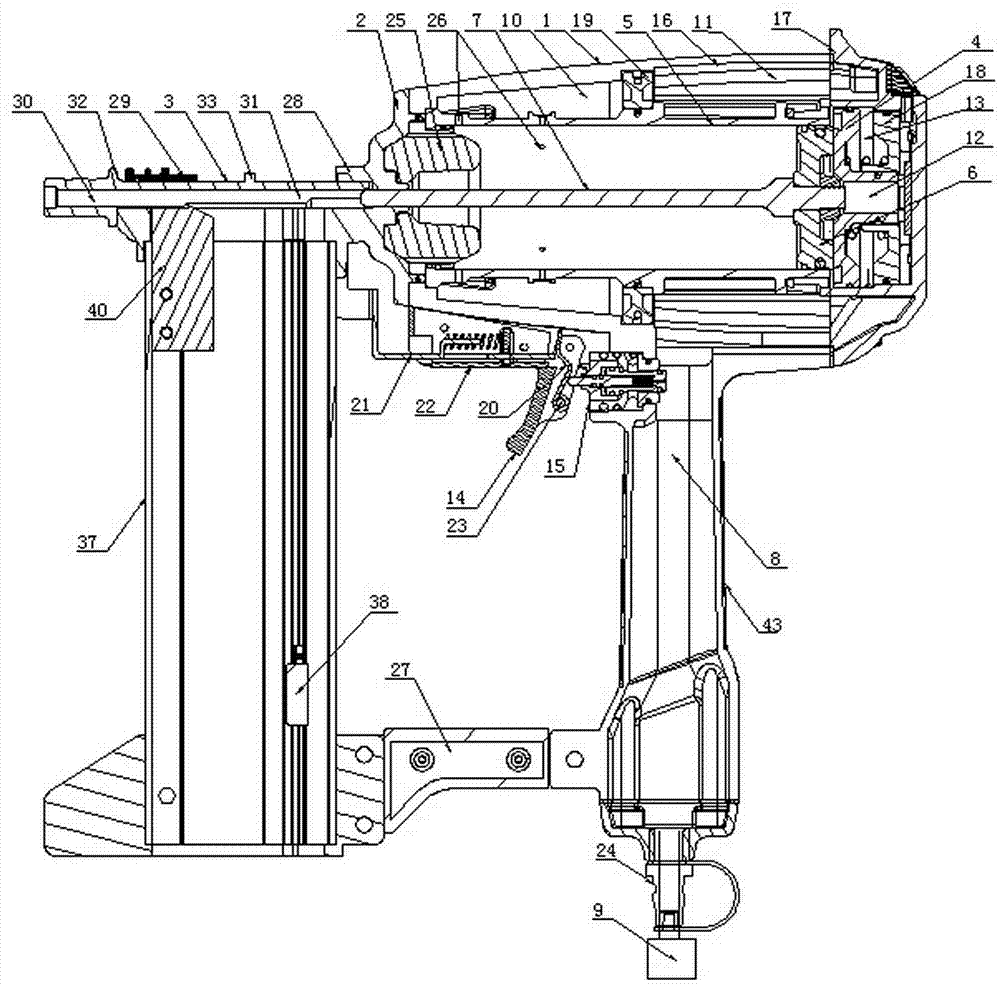

[0058] A compressed air nail gun, comprising a compressed air intake device 9, a gun head, a gun body 1, a safety device and a control device, the gun body 1 is provided with a piston 6 assembly and a balance valve 4, and the piston 6 assembly includes a cylinder body 5, the piston 6 and the piston rod 7 that are slidably arranged in the cylinder body 5, one end of the piston rod 7 is fixedly connected with the piston 6, and the other end cooperates with the gun head to knock out nails, and the lower part of the gun body 1 is provided with an air inlet passage 8, The air intake passage 8 is connected with the compressed air intake device 9, and the safety device is respectively connected with the gun head and the trigger 14 for controlling the action of the trigger 14, and an air return cabin 10 and The air storage chamber 11, the control device includes a trigger 14 and a valve 15, the balance valve 4 is provided with an exhaust passage 12, one side of the balance valve 4 coop...

Embodiment 2

[0070] This embodiment is basically the same as the above-mentioned embodiment, the main difference is that: the gun head includes a barrel base 2 and a gun barrel 3, one side of the gun barrel base 2 is fixedly connected with the gun body 1, and the other side is connected with a gun Pipe sleeve 28, the gun barrel 3 is movably sleeved in the gun sleeve sleeve 28; wherein the gun sleeve sleeve 28 and the gun barrel seat 2 are preferably integrally arranged, and the stability of the gun barrel 3 is better;

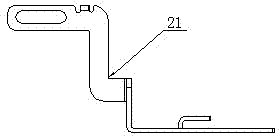

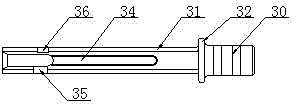

[0071] Another preferred implementation of this embodiment is that the barrel cover 28 is a concave structure, and one side of the concave barrel cover 28 is provided with a through hole and a limit post, and a pressure plate is provided on the opening surface. 29, its bottom surface is provided with nail feeding groove 42, and is fixedly connected with nail box 37; Described gun barrel 3 comprises gun mouth 30 and gun body 31, and limit portion 32 is arranged between gun mo...

Embodiment 3

[0077] This embodiment is basically the same as the above-mentioned embodiment, the main difference is: a nail feeder 38 is arranged in the nail box 37, preferably a coil spring is installed on the nail box 38, and one end of the coil spring is fixed on the upper end of the nail box 37 , to ensure that when nails are loaded into the nail magazine 37 for shooting, the power to replenish nails to the gun barrel 3 can be provided;

[0078] Further, preferably a push rod 39 is set on the nail feeder 38, a notch is set in the nail feed groove 42, when the nails in the nail box 37 are few or shot, the push rod 39 enters through the notch The safety slot 35 prevents empty bullet shooting, so that the gun barrel 3 cannot be pressed down to promote the safety device, which can prevent empty bullet shooting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com