A method of "plugging/regulating/flooding" integration to enhance oil recovery

A technology for oil recovery and oil reservoirs, applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve problems such as difficulty in advancing oil displacement agents, reduce microscopic sweep volume of oil displacement agents, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

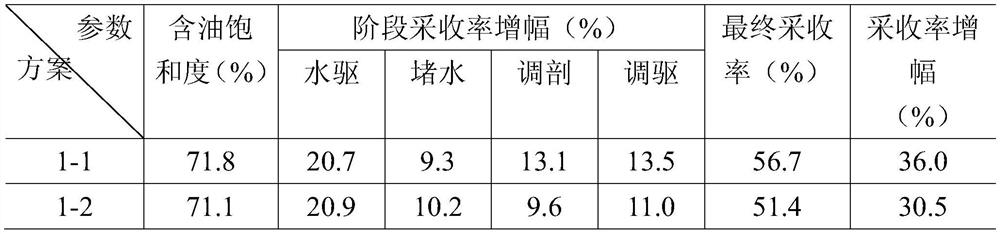

Embodiment 1

[0014] A "plugging / modulation / flooding" integrated method for enhancing oil recovery, comprising the following steps:

[0015] Step 1. Composite gel is prepared by injecting water into the target oil reservoir to prepare composite gel. The composition mass percentage is: 2.5% polyaluminum chloride, 4.5% acrylamide, 0.9% urea, 0.3% ammonium persulfate and 0.3% N , N-methylenebisacrylamide, the initial viscosity of the composite gel is lower than 5mPa. s, the viscosity after gelling exceeds 10×10 4 mPa. s;

[0016] Step 2: Prepare the "polymer microsphere / high-efficiency oil displacement agent" composite system, and use the injection water of the target reservoir to prepare the "polymer microsphere / high-efficiency oil displacement agent" composite system. The components are composed of: the polymer microsphere material is Hydrophobic association polymer gel, the concentration of microspheres is 0.3%, the initial particle size of microspheres is 2.75 μm, and the median particl...

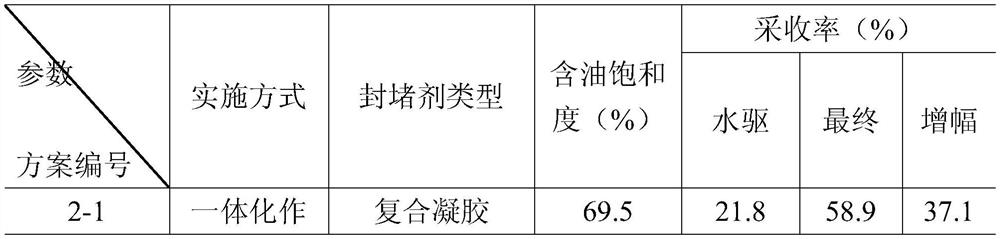

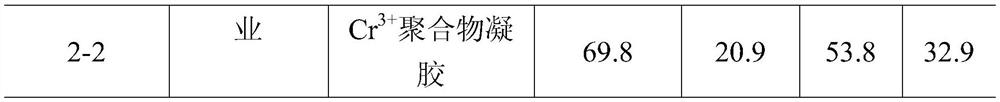

Embodiment 2

[0020] A "plugging / modulation / flooding" integrated method for enhancing oil recovery, comprising the following steps:

[0021] Step 1. Composite gel is prepared by injecting water into the target oil reservoir to prepare composite gel. The composition mass percentage is: 1.5% polyaluminum chloride, 3.0% acrylamide, 0.6% urea, 0.2% ammonium persulfate and 0.2%% N, N-methylenebisacrylamide, the initial viscosity of the composite gel is lower than 5mPa. s, the viscosity after gelling exceeds 10×10 4 mPa. s;

[0022]Step 2: Prepare the "polymer microsphere / high-efficiency oil displacement agent" composite system, and use the injection water of the target reservoir to prepare the "polymer microsphere / high-efficiency oil displacement agent" composite system. The components are composed of: the polymer microsphere material is Hydrophobic association polymer gel, the concentration of microspheres is 0.2%, the initial particle size of microspheres is 1.00 μm, and the median particle...

Embodiment 3

[0026] A "plugging / modulation / flooding" integrated method for enhancing oil recovery, comprising the following steps:

[0027] Step 1. Composite gel is prepared by injecting water into the target oil reservoir to prepare composite gel. The composition mass percentage is: 3.5% polyaluminum chloride, 6.0% acrylamide, 1.2% urea, 0.4% ammonium persulfate and 0.4% N , N-methylenebisacrylamide, the initial viscosity of the composite gel is lower than 5mPa. s, the viscosity after gelling exceeds 10×10 4 mPa. s;

[0028] Step 2: Prepare the "polymer microsphere / high-efficiency oil displacement agent" composite system, and use the injection water of the target reservoir to prepare the "polymer microsphere / high-efficiency oil displacement agent" composite system. The components are composed of: the polymer microsphere material is Hydrophobic association polymer gel, the concentration of microspheres is 0.4%, the initial particle size of microspheres is 4.50 μm, and the median particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com