Grouting machine

A grouting machine and grouting technology, applied in the direction of supply device, liquid cleaning method, clay preparation device, etc., can solve the problems such as not easy to block materials, achieve not easy to block materials, good use effect, improve use effect and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

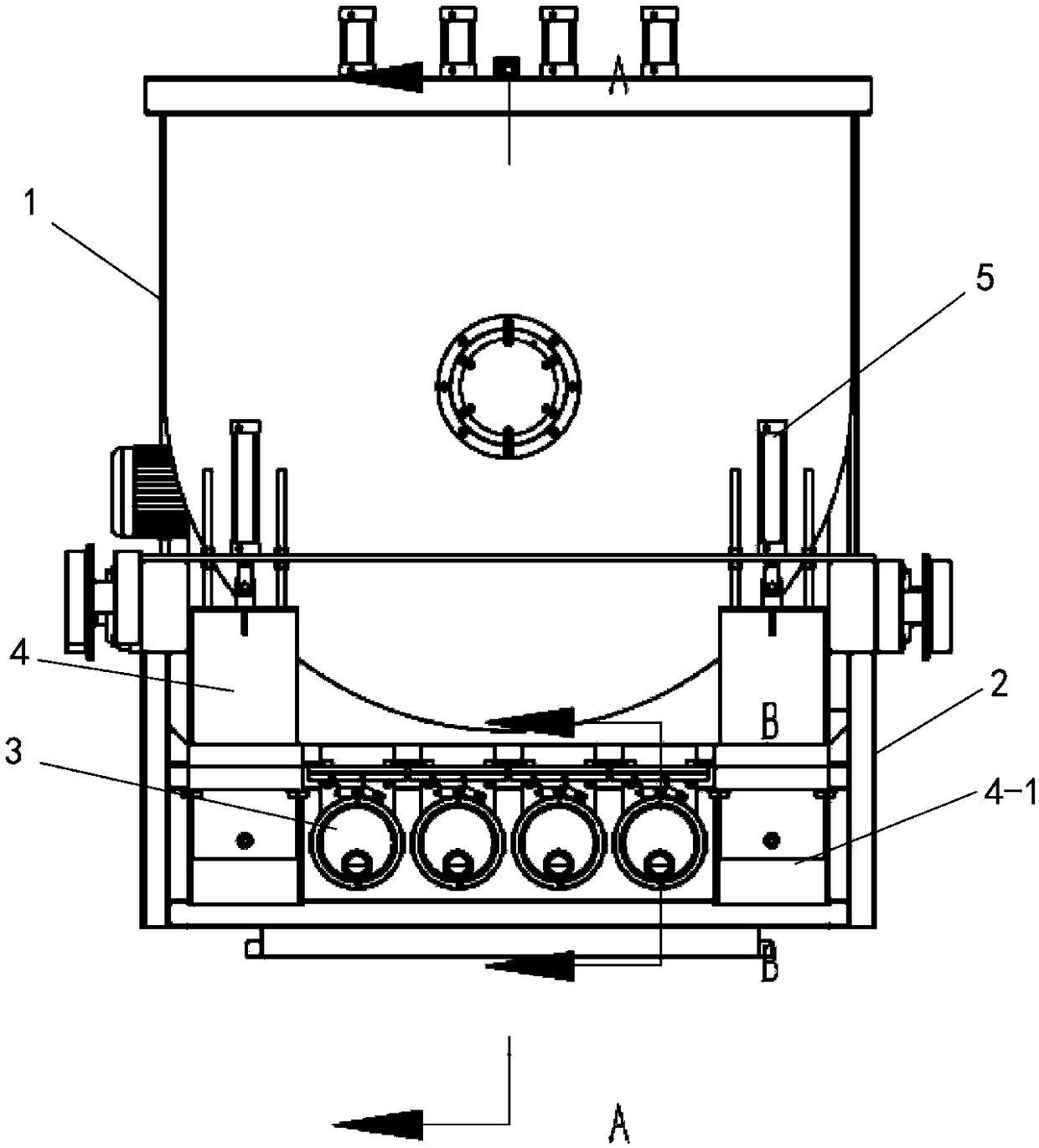

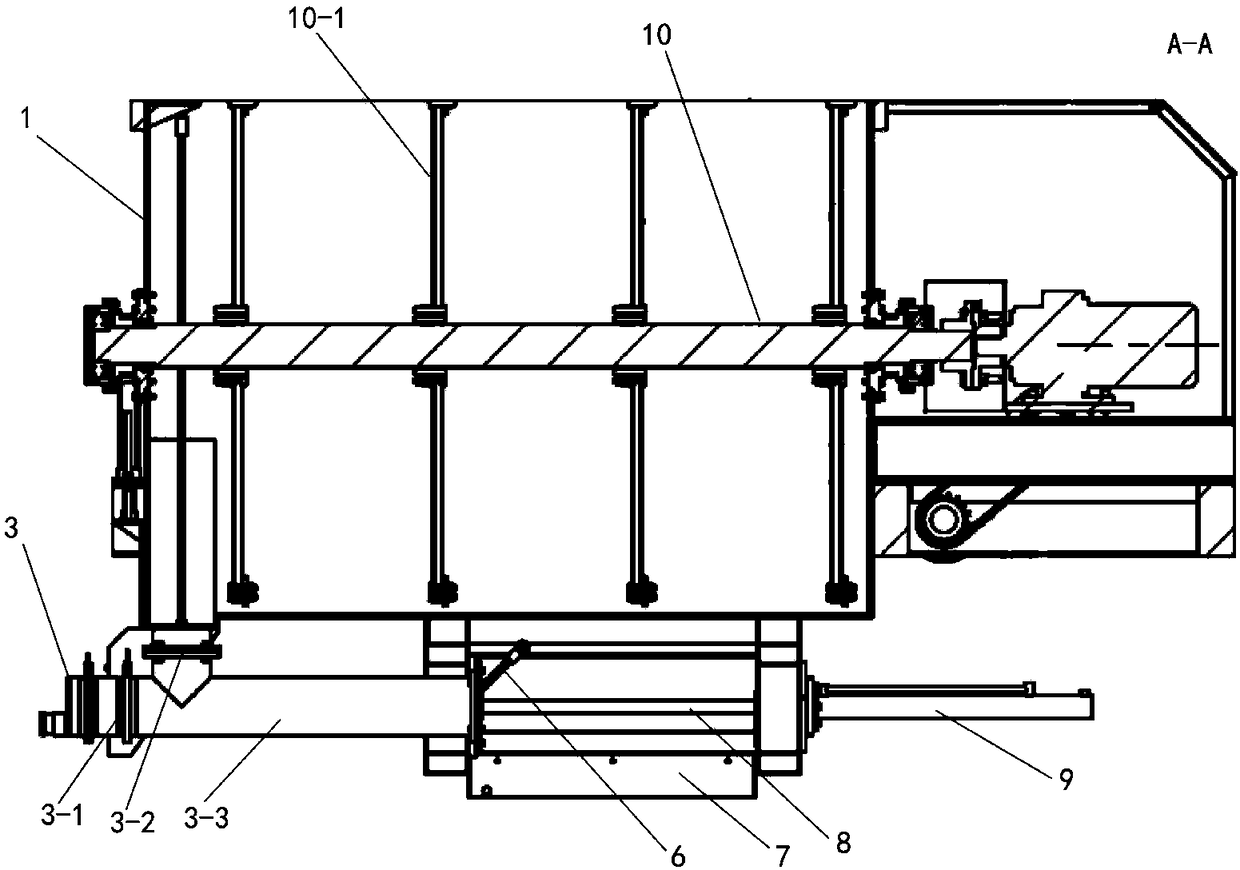

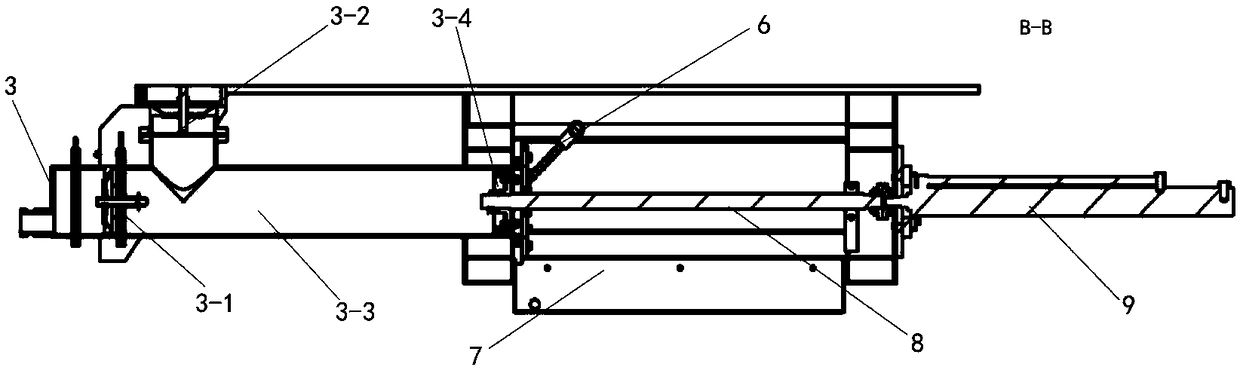

[0015] like Figure 1~3 As shown, a grouting machine includes a mixing tank 1, a grouting cleaning assembly and two free grouting pipelines 4, and the grouting cleaning assembly is distributed on the lower bracket 2 of the grouting machine; the grouting cleaning assembly includes Four grouting pumps 3, cleaning components and four sets of grouting pump driving components; the front part of the grouting pump 3 is provided with a grout inlet and a grout outlet; the grout inlet is provided with a one-way valve 3-2; The slurry outlet is provided with a one-way valve 3-1; the slurry inlet is connected to the bottom of the stirring box 1; the cleaning assembly includes a water pump and a cleaning tank 7; the cleaning tank 7 is distributed in the Below the back of the grouting pump 3; the water inlet of the water pump is distributed in the cleaning tank 7, so that the water in the cleaning tank 7 is circulated; cavity, the water in the cleaning tank 7 is sprayed into the inner cavit...

specific Embodiment 2

[0017] The difference between this embodiment and Embodiment 1 is that the drive assembly of the grouting pump is a drive structure using a drive motor and a crank connecting rod assembly; the drive motor is combined with the grouting pump 3 through the crank connecting rod assembly The piston rod provides reciprocating driving force for the grouting pump 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com