Electrostatic reinforcing bag type dust collector with reverse electric field

A bag-type dust collector and dust collector technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode structure, etc., can solve the problems that the electrostatic attraction and electric field force cannot be taken into account at the same time, it is difficult to clean dust, and has not been well solved. Achieve the effects of enhancing the surface filtering effect, increasing the filtering resistance, and improving the dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

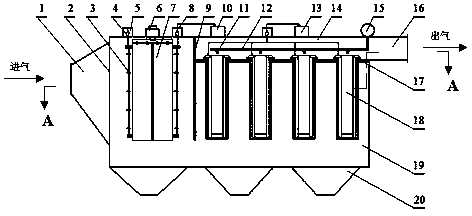

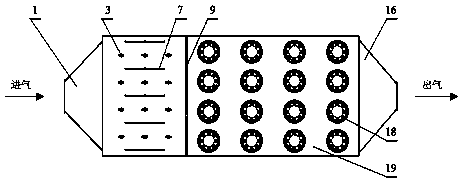

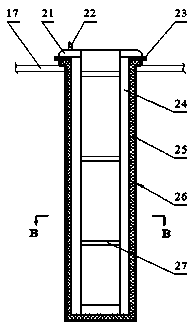

[0048] A reverse electric field electrostatically enhanced bag filter such as figure 1 and figure 2 shown. The dust collector consists of an air intake box 1 , a dust collector body 2 , an air outlet box 16 and an ash hopper 20 . The inlet box 1 is fixedly connected to the inlet end of the dust collector body 2, the air outlet box 16 is fixedly connected to the outlet end of the dust collector body 2, and the ash hopper 20 is fixedly connected to the bottom of the dust collector body 2 shell.

[0049] The structure of the dust collector body 2 is: a baffle 9 is arranged in the housing of the dust collector body 2, and the baffle 9 is perpendicular to the air intake direction, and the baffle 9 is connected to the top of the housing of the dust collector body 2 and the two sides of the housing. The inner wall of the side is sealed and fixedly connected, and the lower end of the spoiler 9 is suspended. The baffle 9 divides the dust collector body 2 into two front and rear are...

Embodiment 2

[0059] A reverse electric field electrostatically enhanced bag filter. Except following technical parameter, all the other are with embodiment 1.

[0060] The distance between the corona pole line 3 and the dust collection pole plate 7 is 200mm;

[0061] The shown corona pole lines 3 are 3 rows, 4 in each row; the dust collecting pole plates 7 are 4 rows, 3 in each row;

[0062] The pitch of filter bag unit 18 is 220-260mm;

[0063] The corona pole wire 3 is a circular wire;

[0064] The output voltage of the precharged DC high voltage power supply 10 is 80kV;

[0065] The grounded dust collecting pole plate 7 is a Z-shaped plate.

Embodiment 3

[0067] A reverse electric field electrostatically enhanced bag filter. Except following technical parameter, all the other are with embodiment 1.

[0068] The distance between the corona pole line 3 and the dust collecting plate 7 is >50mm and <200mm;

[0069] The shown corona pole wires 3 are 5 to 10 rows, 5 to 6 in each row; the dust collecting pole plates 7 are 5 rows, 4 to 5 in each row;

[0070] The pitch of filter bag unit 18 is 240-280mm;

[0071] The corona pole line 3 is a star line;

[0072] The output voltage of the pre-charged DC high-voltage power supply 10 is >20kV and <80kV;

[0073] The grounded dust collecting pole plate 7 is a porous plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com