Guidewire

A technology of guide wire and coil, applied in the direction of guide wire, etc., can solve the problems of inability to transmit, poor wettability, and detachment of coil wire, etc., and achieve the effects of preventing detachment, improving torque transmission, and reliable tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

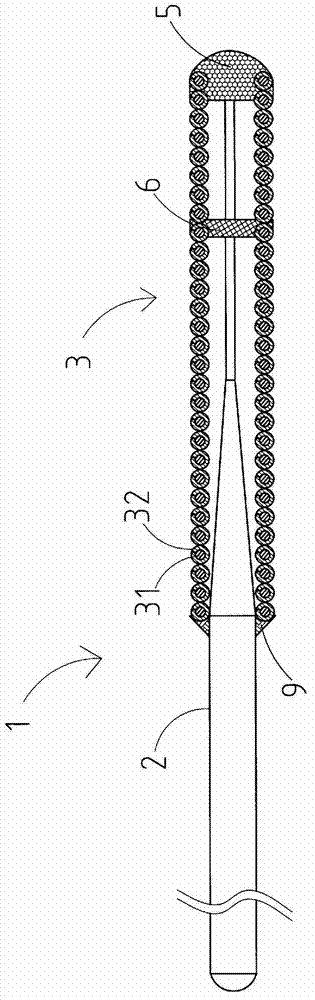

[0031] figure 1 It is an overall view showing the guide wire 1 according to the first embodiment of the present invention.

[0032] In addition, in figure 1 In the description, for convenience of description, the left side is referred to as the "proximal side" and the right side is described as the "tip side".

[0033] In addition, in figure 1 In FIG. 2 , the longitudinal direction of the guide wire 1 is shortened and the whole is schematically shown for easy understanding, so the overall size is different from the actual size.

[0034] exist figure 1 Among them, the guide wire 1 includes: a mandrel 2; a coil body 3 covering the front end of the mandrel 2; In the proximal direction of the front end portion 5 , the coil body 3 and the mandrel 2 are fastened by the intermediate fastening portion 6 , and the proximal end of the coil body 3 and the mandrel 2 are fastened by the proximal fastening portion 9 .

[0035] Furthermore, the front end portion 5 , the intermediate fas...

no. 2 approach >

[0059] Below, use figure 2 , the guide wire 11 of the second embodiment will be described focusing on differences from the first embodiment. The same reference numerals are assigned to the same parts as in the first embodiment in the drawings.

[0060] Also, for ease of understanding, figure 2 The length direction of the guide wire 11 is shortened, and the whole of the guide wire 11 is schematically shown, so the overall size is different from the actual size.

[0061] exist figure 2 Among them, the coil wire material of the coil body 13 of the guide wire 11 includes a core wire 31 composed of a tungsten wire, and a side wire 132 composed of two stainless steel wires wound so as to cover the outer periphery of the core wire 31, except the above-mentioned Other than this point, it has the same form as 1st Embodiment.

[0062] In this way, in the guide wire 11 of the second embodiment, the coil wire material of the coil body 13 includes a core wire 31 composed of one tung...

no. 3 approach >

[0065] Second, use image 3 (a), image 3 (b) and image 3 (c) The guide wire 21 of the third embodiment will be described focusing on the differences between the first embodiment and the second embodiment. The same symbols are assigned to the same parts as those of the first embodiment and the second embodiment in the drawings.

[0066] Also, for ease of understanding, image 3 (a) The longitudinal direction of the guide wire 21 is shortened, and the entire guide wire 21 is schematically shown, so the overall size is different from the actual size. in addition, image 3 (b) is enlarged image 3 (a) A diagram of part A, image 3 (c) means image 3 (b) is a diagram of a modified example of the coil wire of the coil body.

[0067] exist image 3 (a) and image 3 In (b), for the guide wire 21 , the coil wire material of the coil body 23 includes a core wire 31 made of one tungsten wire, and eight stainless steel wires wound so as to cover the outer circumference of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com