Application of salvianolic acid A composition for preparing medicines for preventing and/or treating cerebral thrombosis

A technology of salvianolic acid and composition, which is applied in the field of preparation of drugs for preventing and or treating cerebral thrombosis, can solve the problems of low natural content of salvianolic acid A, neglect, and difficulty in separation and purification, and achieves saving production cycle, saving cost, The effect of increasing conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

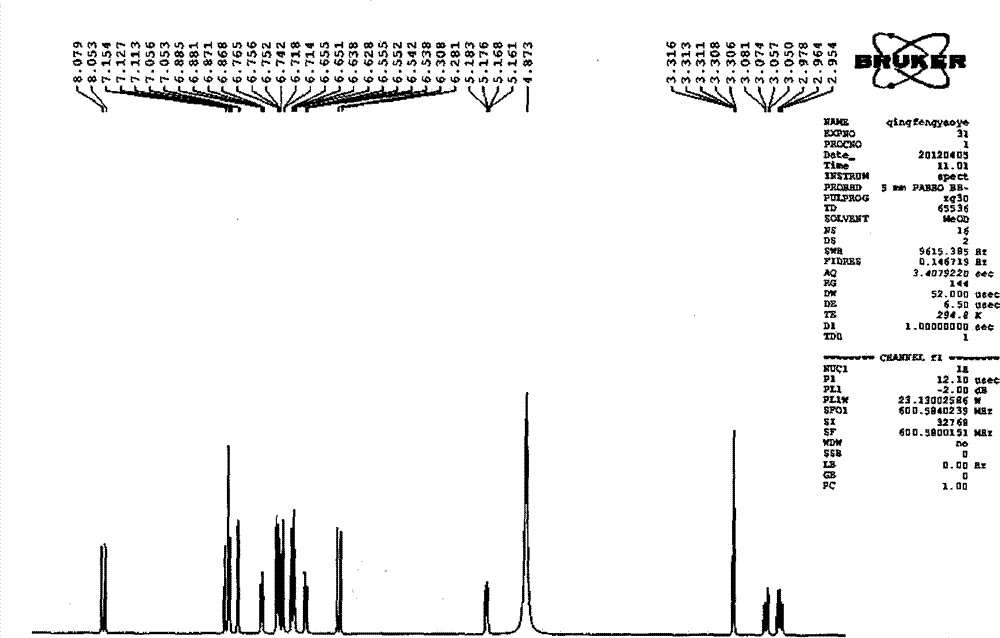

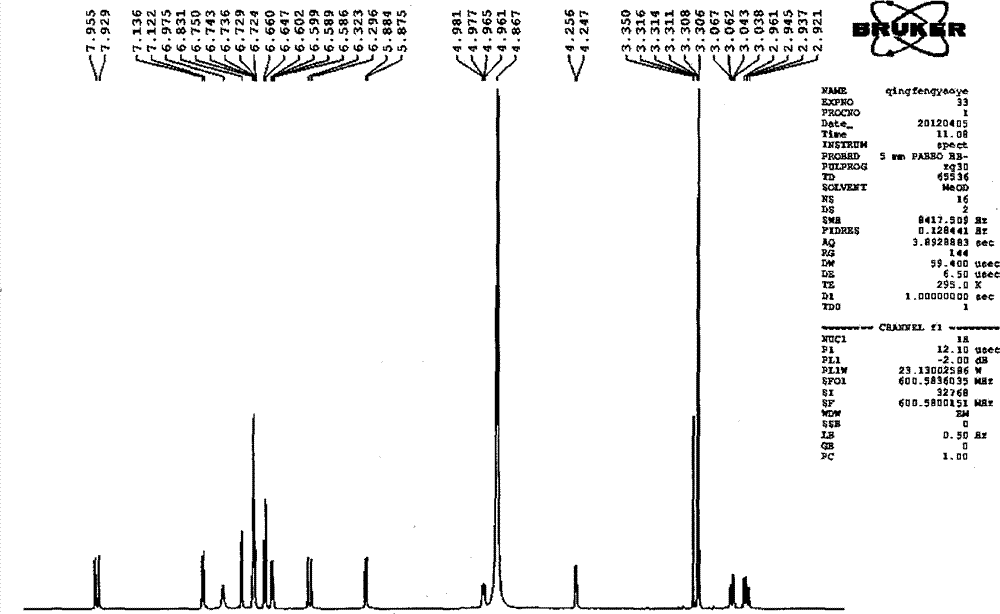

Image

Examples

Embodiment 1

[0110] Take Danshen medicinal material, crush it into 6-mesh granules, add 7 times the amount of 92°C water each time, warm soak and extract 3 times, and stir at a speed of 25 rpm, and warm soak and extract for 3 hours each time; the extract is concentrated under reduced pressure to relative Density 1.20 (60°C), add ethanol to make the alcohol content at 70%, let it stand, filter, the filtrate is decompressed to recover ethanol and concentrate until it has no alcohol smell; add water to dilute to contain salvianolic acid B20mg per 1ml, use 10% for aqueous solution Adjust the pH to 4.0 with sodium hydroxide, add 0.5% ZnCl 2As a catalyst, heat and transform at 120°C for 4 hours, adjust the pH value of the transformation liquid to 2.5 with 20% phosphoric acid, centrifuge, concentrate the supernatant under reduced pressure to contain 3 mg of salvianolic acid A per 1 ml, and perform HPD-100 macroporous resin column chromatography For separation, the ratio of salvianolic acid A load...

Embodiment 2

[0113] Take Salvia miltiorrhiza, cut into decoction pieces, add 8 times the amount each time, soak in water at 90°C for 3 times, and stir at a speed of 20 rpm, and extract with warm soaking for 2.5 hours each time; the extract is concentrated under reduced pressure to a relative density of 1.10 (60 ℃), add ethanol to make the alcohol content at 75%, let it stand, filter, and the filtrate reclaims ethanol under reduced pressure and concentrates to no alcohol smell; add water to dilute to contain salvianolic acid B15mg per 1ml, adjust the aqueous solution with 10% potassium hydroxide pH to 5.0, add 0.6% FeCl3 as a catalyst, transform by heating at 120°C for 3.5 hours, adjust the pH value of the transformation solution to 2.5 with 15% hydrochloric acid, centrifuge, and concentrate the supernatant under reduced pressure to contain 5 mg of salvianolic acid A per 1 ml. HPD-100 macroporous resin column chromatography separation, the ratio of salvianolic acid A loading to macroporous a...

Embodiment 3

[0116] Take Danshen medicinal material, crush it into 4-mesh to 10-mesh granules, add 9 times the amount each time, soak in water at 85°C for 2 times, and stir at a speed of 30 rpm, and extract with warm soaking for 3.5 hours each time; the extract is concentrated under reduced pressure to Relative density 1.18 (60°C), add ethanol to make the alcohol content 75%, let it stand, filter, the filtrate recovers ethanol under reduced pressure and concentrates until there is no alcohol smell; add water to dilute to contain salvianolic acid B18mg per 1ml, and use 10 mg of salvianolic acid B in the aqueous solution % sodium carbonate to adjust the pH to 5.2, add 0.6% AlCl3 as a catalyst, convert by heating at 123°C for 4.5 hours, adjust the pH of the conversion solution to 2.8 with 15% nitric acid, centrifuge, and concentrate the supernatant under reduced pressure to contain salvianol per 1ml Salvianolic acid A6mg, separated by HPD-100B macroporous resin column chromatography, the ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com