Yeast protein and preparation method thereof, food prepared from the protein as raw material and preparation method thereof

A yeast protein and food technology, applied in the field of yeast protein and its production method, can solve the problems of difficult quality assurance, rarely meeting the requirement of protein supplementation, long storage time of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

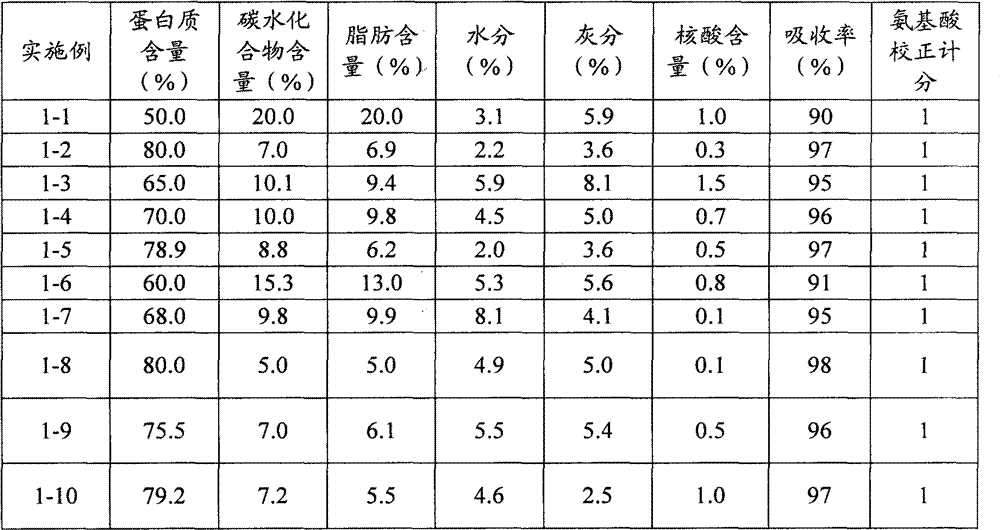

Examples

Embodiment 1-1

[0033] Using the low-nucleic acid yeast of Angel Yeast Co., Ltd. as raw material, the protein is extracted to obtain a water-soluble yeast protein. The process is as follows:

[0034] (1) Superfine pulverization treatment: take 1000g of low-nucleic acid yeast after being pulverized by a superfine pulverizer, and use tap water to make a solution with a concentration of 15% by weight;

[0035] (2) Enzymolysis: adjust the pH to 4.8 with 0.1mol / L hydrochloric acid, add β-glucanase to 0.1% of the weight of low-nucleic acid yeast, and keep warm in a constant temperature water bath at 50°C for 5 hours;

[0036] (3) Alkali treatment: adjust the pH to 9 with 0.1mol / L sodium hydroxide, and keep it warm in a constant temperature water bath at 50°C for 0.5 hours;

[0037] (4) Acid precipitation: then centrifuge to take the supernatant, adjust the pH to 4.5 with prepared 0.1mol / L hydrochloric acid, cool and stand for 1 hour;

[0038] (5) Separation, washing, and drying: centrifugal separ...

Embodiment 1-2

[0041] The test was carried out according to the following Table 3, and the sequence of the steps was consistent with that of Example 1-1.

Embodiment 1-3

[0043] The test was carried out according to the following Table 3, and the sequence of the steps was consistent with that of Example 1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com