Drive system of synchronized electric motor

A synchronous motor and drive system technology, applied in AC motor control, electronic commutation motor control, control system and other directions, can solve the problems of low sensitivity and submerged position information in noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

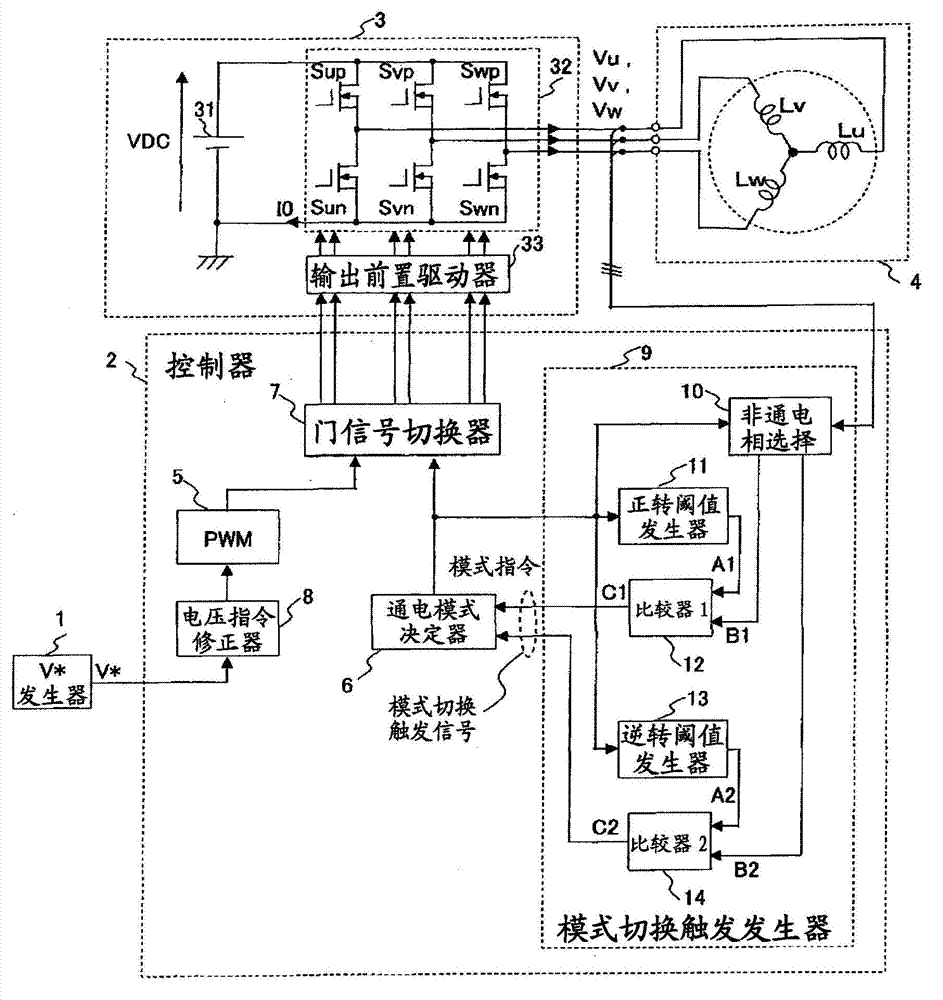

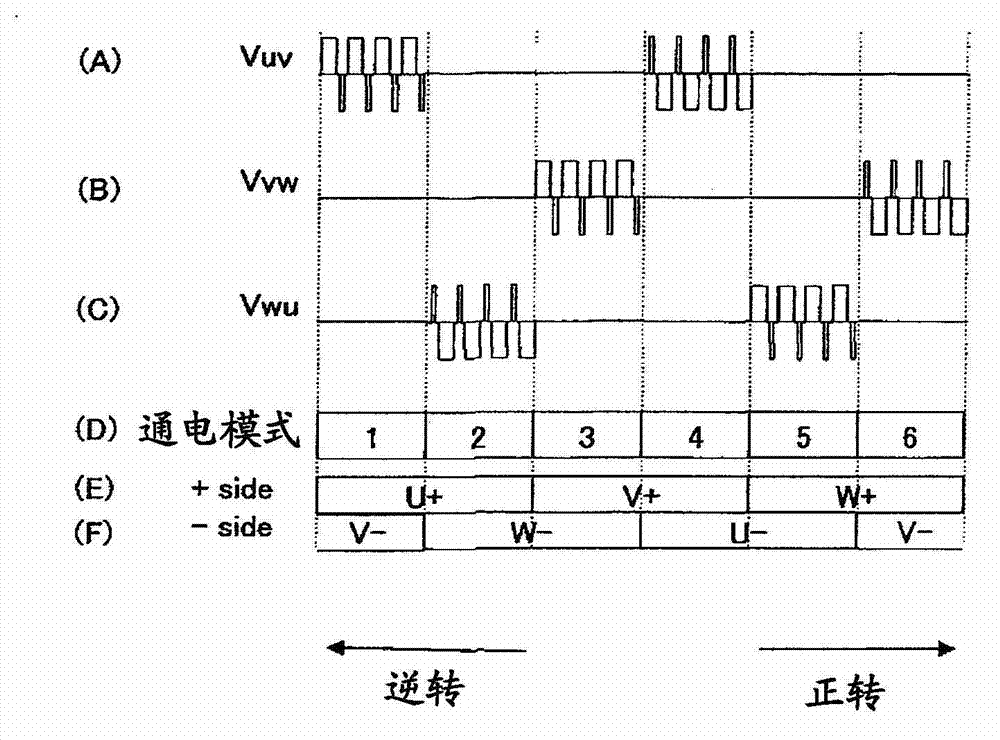

[0049] Below, use Figure 1 to Figure 23 , the configuration and operation of a drive system for a synchronous motor according to an embodiment of the present invention will be described.

[0050] First, use figure 1 The overall configuration of the drive system of the synchronous motor according to the present embodiment will be described.

[0051] figure 1 It is a block diagram showing the overall configuration of a drive system for a synchronous motor according to an embodiment of the present invention.

[0052] The synchronous motor drive system of this embodiment includes a voltage command generator (V* generator) 1 , a controller 2 , an inverter 3 , and a synchronous motor (PM motor) 4 .

[0053] The PM motor 4 is a three-phase synchronous motor holding a plurality of permanent magnets on the rotor.

[0054] The V* generator 1 is a controller positioned upstream of the controller 2 that generates a voltage command V* to be applied to the PM motor 4 . For example, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com