Method for manufacturing spherical aluminum nitride powder

一种制造方法、氮化铝的技术,应用在化学仪器和方法、氮化合物、无机化学等方向,能够解决制造成本提高、工序多等问题,达到导热率高、高导热率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

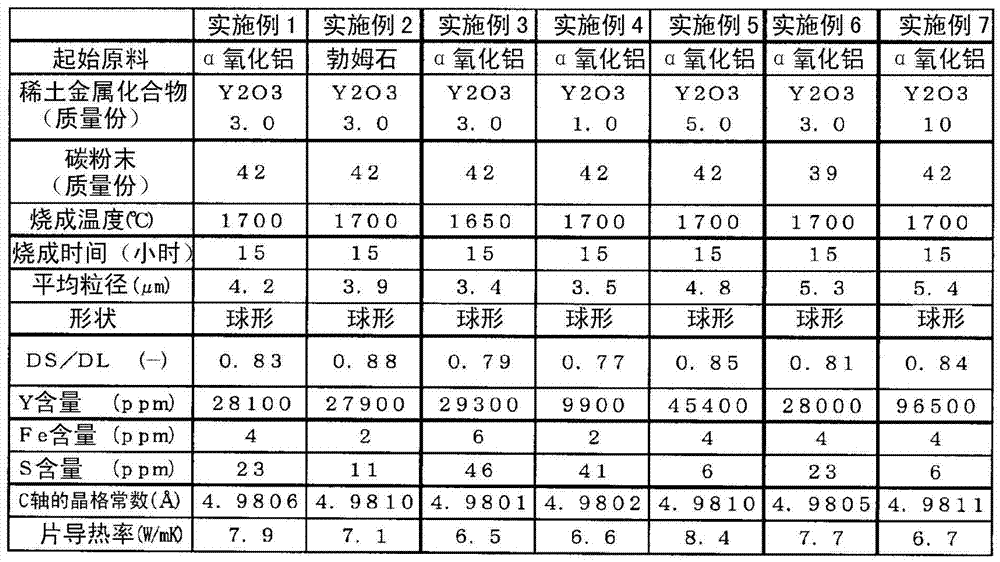

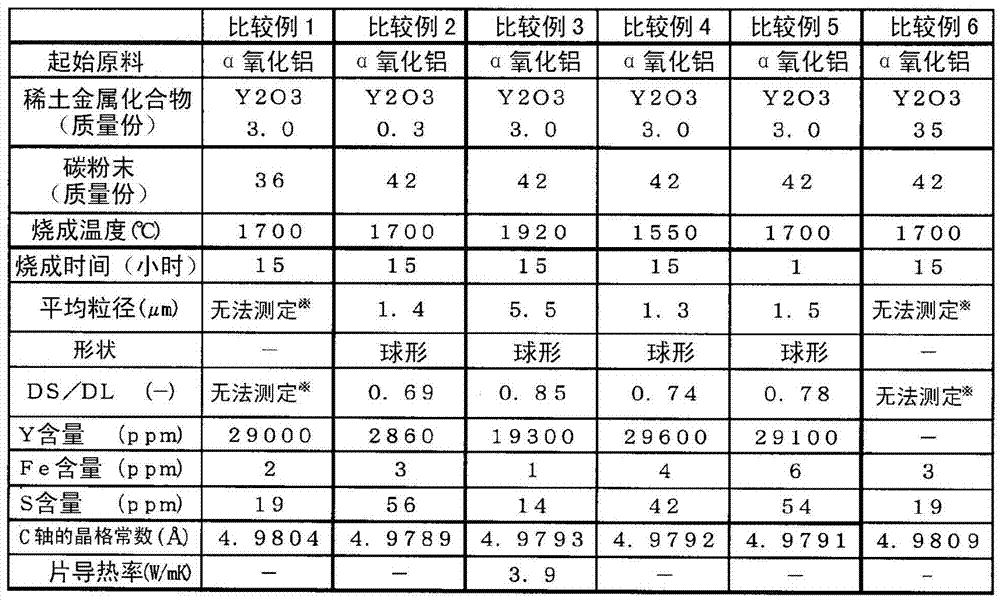

[0081] The present invention will be described more specifically below, but the present invention is not limited by these examples. Various physical properties in Examples and Comparative Examples were measured according to the following methods.

[0082] (1) Average particle size

[0083] The sample was dispersed in a sodium pyrophosphate aqueous solution using a homogenizer, and the average particle diameter (D 50 ).

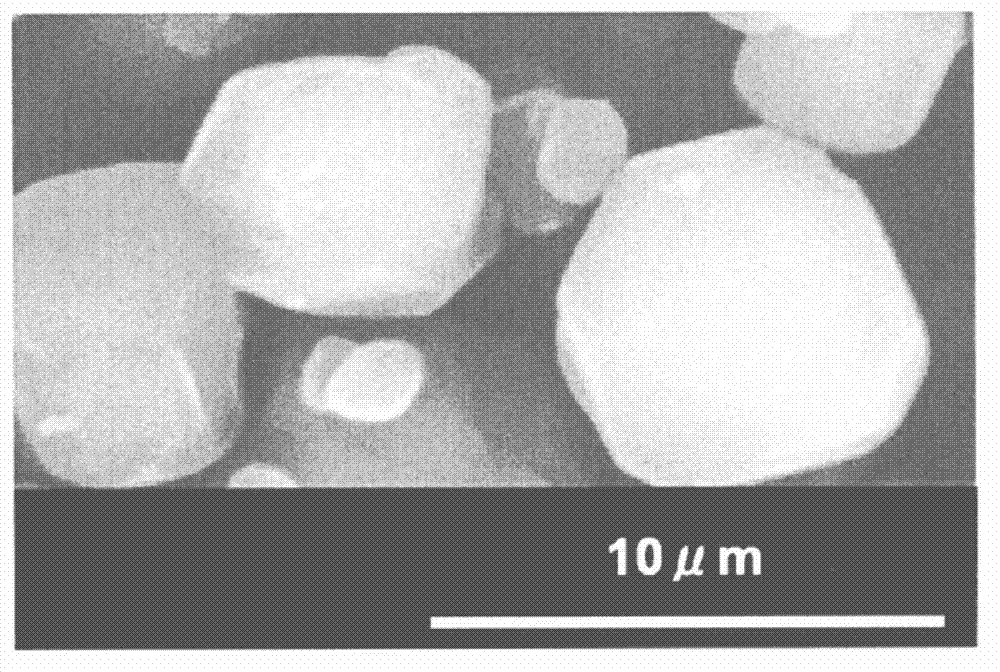

[0084] (2) Particle shape

[0085] The shape of the aluminum nitride powder was observed with a scanning electron microscope (S-2600N manufactured by Hitachi, Ltd.).

[0086] (3) Sphericity of particles (ratio of long diameter to short diameter)

[0087] Select any 100 particles from the photo image of the electron microscope, use a ruler to measure the long diameter (DL) and short diameter (DS) of the particle image, and the average value of the ratio (DS / DL) is used as the benchmark of sphericity.

[0088] (4) Cationic impurity content

[0089] Cationic ...

Embodiment 2

[0103] In addition to changing the Al source of α-alumina to an average particle size of 1.0μm and a specific surface area of 12.7m 2 / g of boehmite, a spherical aluminum nitride powder was produced in the same manner as in Example 1.

[0104] Table 1 shows the average particle size and shape of the obtained spherical aluminum nitride powder, the ratio of the major axis to the minor axis of the aluminum nitride particles, the content of cationic impurities, and the C-axis lattice constant of the aluminum nitride crystal. Furthermore, using the obtained aluminum nitride powder, a sheet was produced in the same manner as in Example 1, and the thermal conductivity was measured. The results are shown in Table 1 together.

Embodiment 3

[0106] A spherical aluminum nitride powder was produced in the same manner as in Example 1 except that the firing temperature was set to 1650°C.

[0107] Table 1 shows the average particle size and shape of the obtained spherical aluminum nitride powder, the ratio of the major axis to the minor axis of the aluminum nitride particles, the content of cationic impurities, and the C-axis lattice constant of the aluminum nitride crystal. Furthermore, using the obtained aluminum nitride powder, a sheet was produced in the same manner as in Example 1, and the thermal conductivity was measured. The results are shown in Table 1 together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com