Stator punching of single-phase capacitor-run motor

A stator punching and motor technology, applied in the magnetic circuit shape/style/structure, magnetic circuit static parts and other directions, can solve the problem that the efficiency and temperature rise cannot meet the requirements, the motor efficiency cannot be improved, and the effective utilization of windings is low, etc. problems, to facilitate automated production, improve motor efficiency, and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

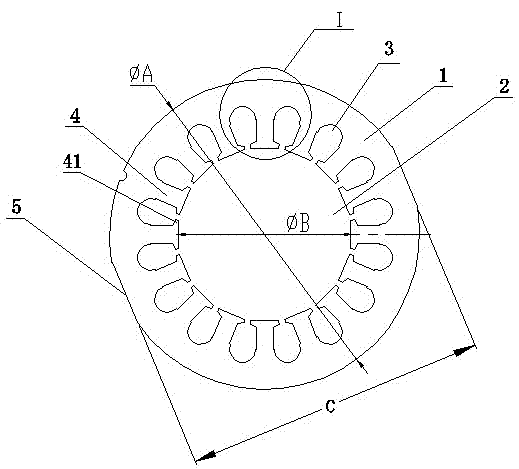

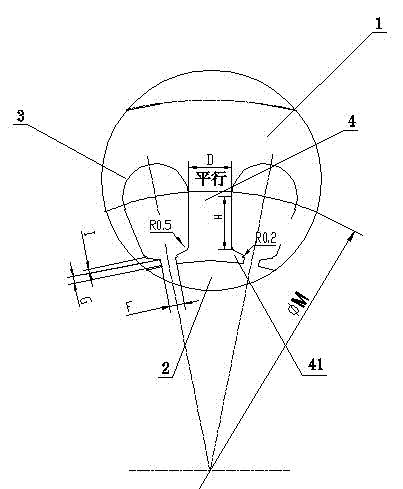

[0016] The structure diagram of the present invention is as figure 2 , image 3 , the center of the stator punch 1 of the present invention is provided with a hollow inner circular hole 2, and several winding slots 3 are arranged along the radial direction of the stator punch 1, and the number of winding slots 3 arranged along the radial direction of the stator punch 1 is 16 and Evenly distributed, stator teeth 4 are formed between adjacent winding slots 3, salient poles 41 are formed at the ends of the stator 4, and two opposite 1 mm trimmings 5 are provided on the outer diameter of the stator punch 1. Among them, the dimensions of the stator punch 1, the hollow inner hole 2 and the winding slot 3 are as follows:

[0017] The diameter ΦA of the outer circle of the stator punching sheet 1 is: 88.00-88.03mm, the diameter ΦB of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com